Page 20 | Stellar

®

Heavy-Duty Telescopic Crane Owner’s Manual

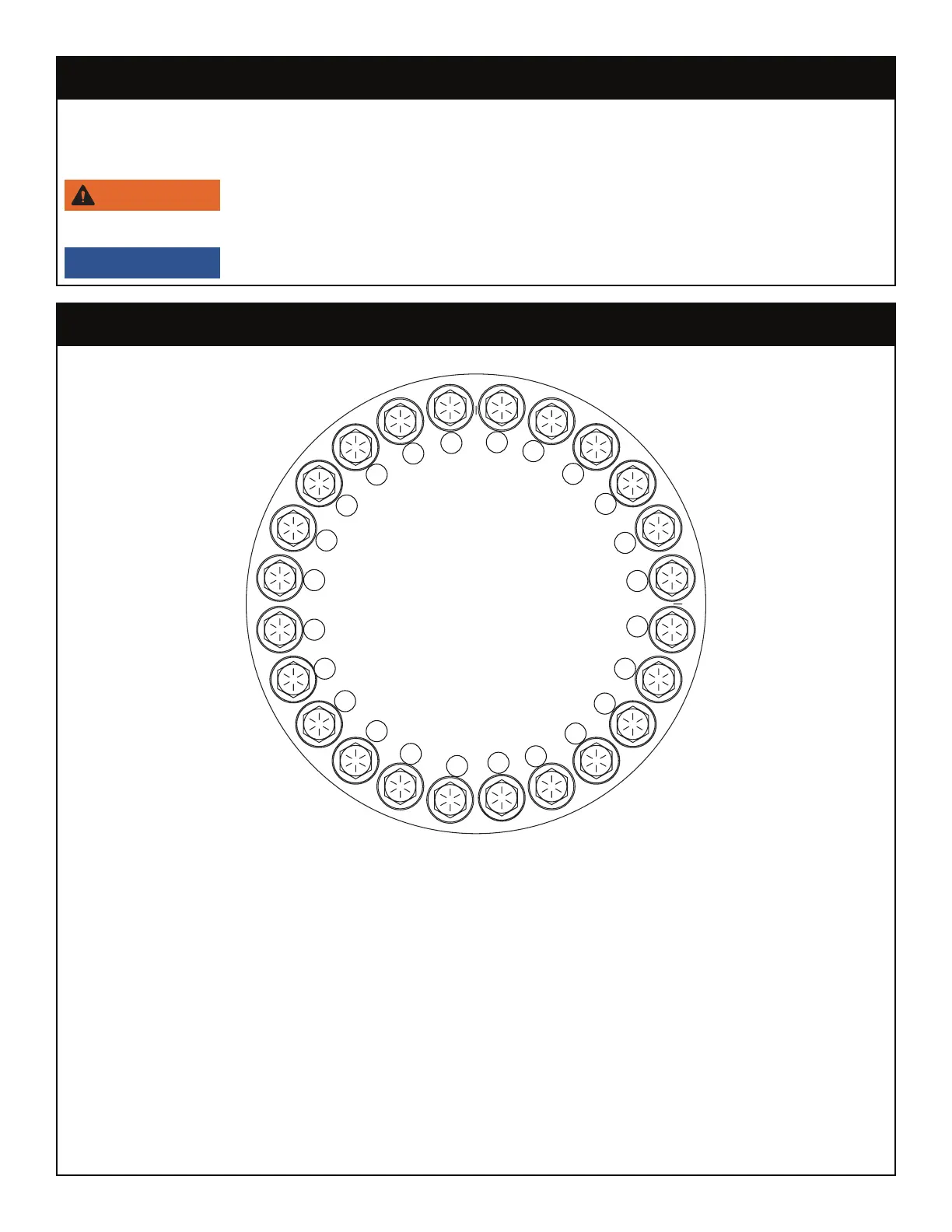

Step 1: Refer to the Torque Data Chart on the previous page to determine the proper

torque value based on the size of bolt used.

Step 2: Torque all bolts to approximately 40% of the specied torque value using the

tightening sequence shown above. Note: The number of bolts may be different

than shown in the diagram but the sequence will work using the same pattern in

relation to Bolt #1.

Step 3: Torque all bolts to 75% of the specied torque value using the tightening sequence

shown above.

Step 4: Torque all bolts to the listed torque value using the tightening sequence shown

above.

Rotation Gear Bearing Thread Tightening Procedure

Once a bolt has been torqued to 75% of its proof load and then removed, the

torque coefcient may no longer be the same as when the bolt was new thus giving

indeterminate damp loads after torquing.

Anytime a gear-bearing bolt is removed, it must be replaced with a new

bolt of the identical grade and size.

Always use Red Loctite Threadlocker sealant to secure the new bolt.

Gear-Bearing Bolt Maintenance

1

2

3

4

5

6

7

8

9

24

10

11

1213

14

15

16

17

18

19

20

21

22

23

Loading...

Loading...