Stellar

®

Heavy-Duty Telescopic Crane Owner’s Manual | Page 25

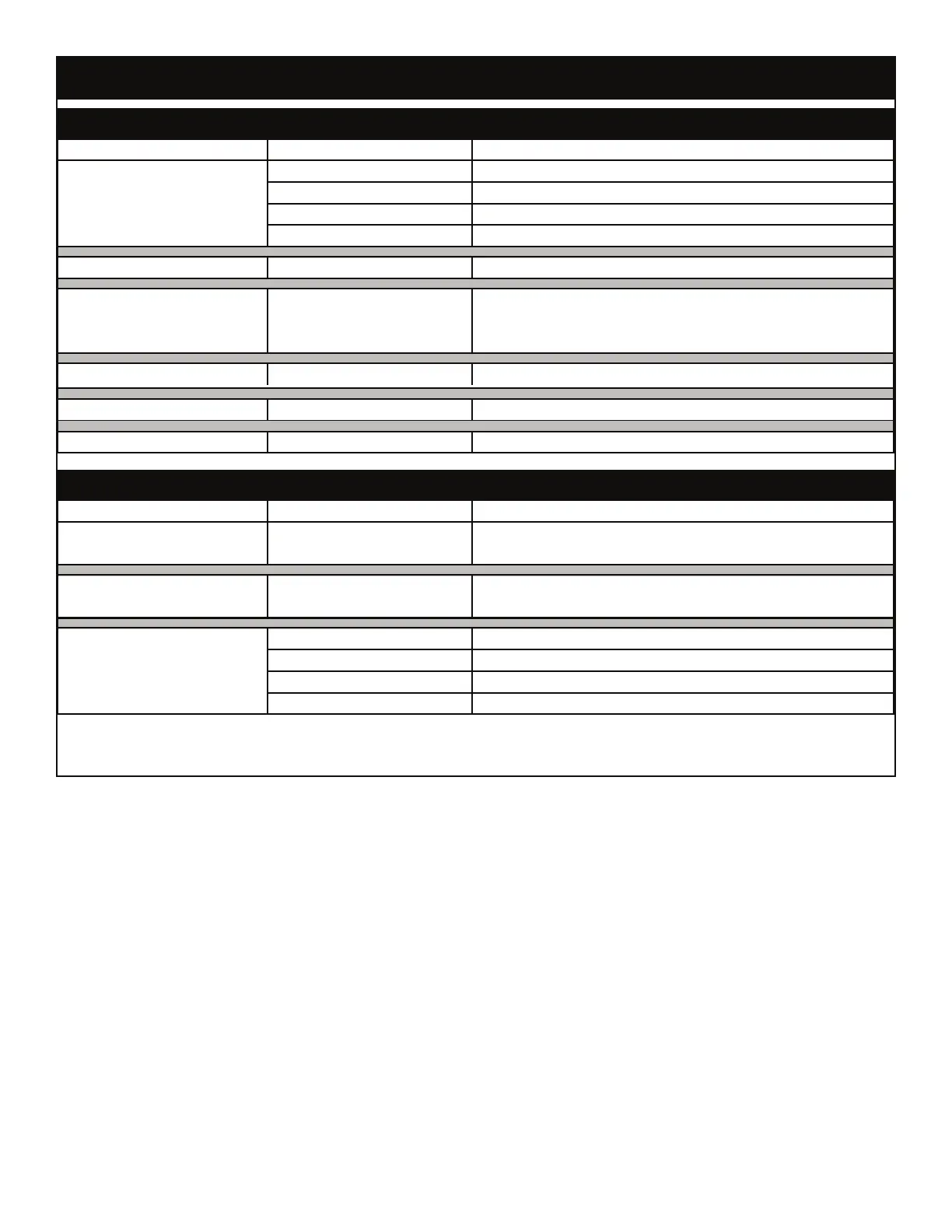

Com

onent Location Recommendation

Reservoir

Below –5˚F High VI, low pour, ISO 22, AW hydraulic oil

-5˚F to 90˚F High VI, low pour, ISO 32, AW hydraulic oil

Above 90˚F ISO 46, AW hydraulic oil

O

en Gear Teeth Crane Rotation Gear Mol

Grease 936SF Heav

Stellar PN 4460

Worm Drive Bearings

(including turntable

bearin

inner race

Crane Rotation Gear,

Inside Crane

Com

artment

EP2 Lithium Complex Grease (Stellar PN 78090)

C

linders Crane Pivot Areas EP2 Lithium Com

lex Grease

Stellar PN 78090

Crane Pins & Bushin

s Crane Pivot Points EP2 Lithium Com

lex Grease

Stellar PN 78090

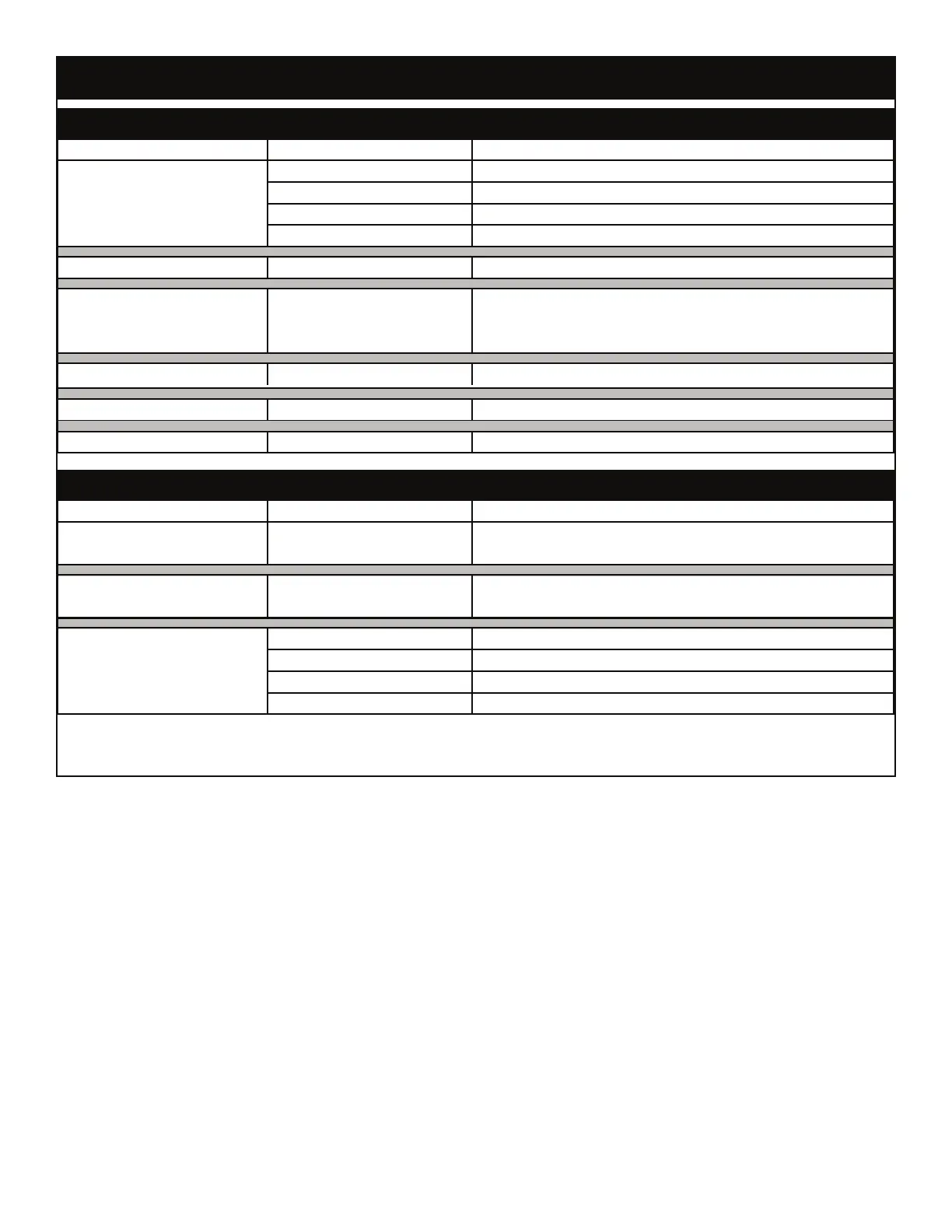

Com

onent Location Recommendation

Reciprocating Single

Sta

e

Compressor Crankcase ISO 100 compresser oil

Reciprocating Double

Sta

e

Compressor Crankcase ISO 100 compresser oil

Compressor Crankcase

-15˚F to 86˚F Synthetic performing ISO 32 compresser oil

-23˚F to 100˚F Synthetic performing ISO 46 compresser oil

32˚F to 113˚F Synthetic performing ISO 68 compresser oil

Compressor Lubrication

Crane Lubrication

Hydraulic System

Screw Compressor

Wear Pad Lubrication Extension BoomsS

nthetic lubricant containin

Teflon®

Lubrication Recommendations

Loading...

Loading...