21

For Example: 250

o

F = (250

o

F/20Ma - 4 mA) 20mA + b

-62.5 = b (”

”)

Retransmission Of

Process Variable

The M2B is capable of re-transmitting the process output “

'

''

'

” or the set

point input “

” via a 0-20mA analog signal. If a 4 to 20mA output is

desired, follow the scaling calculation outlined in the remote set point

section. Insert the low and high values for “

” and “

”.

Second Set Point

Input

The M2B is provided with a secondary set point “

” pre-programmed for

0

o

F (-17.7

o

C), but is adjustable. When an external switch contact is closed,

the controller will switch to this set point and will display “

” . This will

occur when SP2 is set to 0

o

F and the actual setpoint is any other value.

The controller will revert to “

” when the contact is released and unit

returns to run mode.

Flow Meter

The M2B is capable of displaying and alarming process flow in gallons per

minute (GPM) or liters per minute (LPM), via a factory installed flow sensor.

The M2B is capable of accepting numerous flow sensors.

Note:

Please contact the factory if the flow readout oscillates or appears

erratic for evaluation, calibration, and installation instructions.

The M2B is equipped with a software activated digital filter. The filter is

adjustable from 0-100, the larger the number the greater the signal

dampening. Consult the factory for further information and access.

Remote

Thermocouple

Monitor

Monitors type “J” thermocouple input. Depress

INDEX

key until “

)

))

)

”

appears. Temperature is displayed in process display window. See Figure-1

for location.

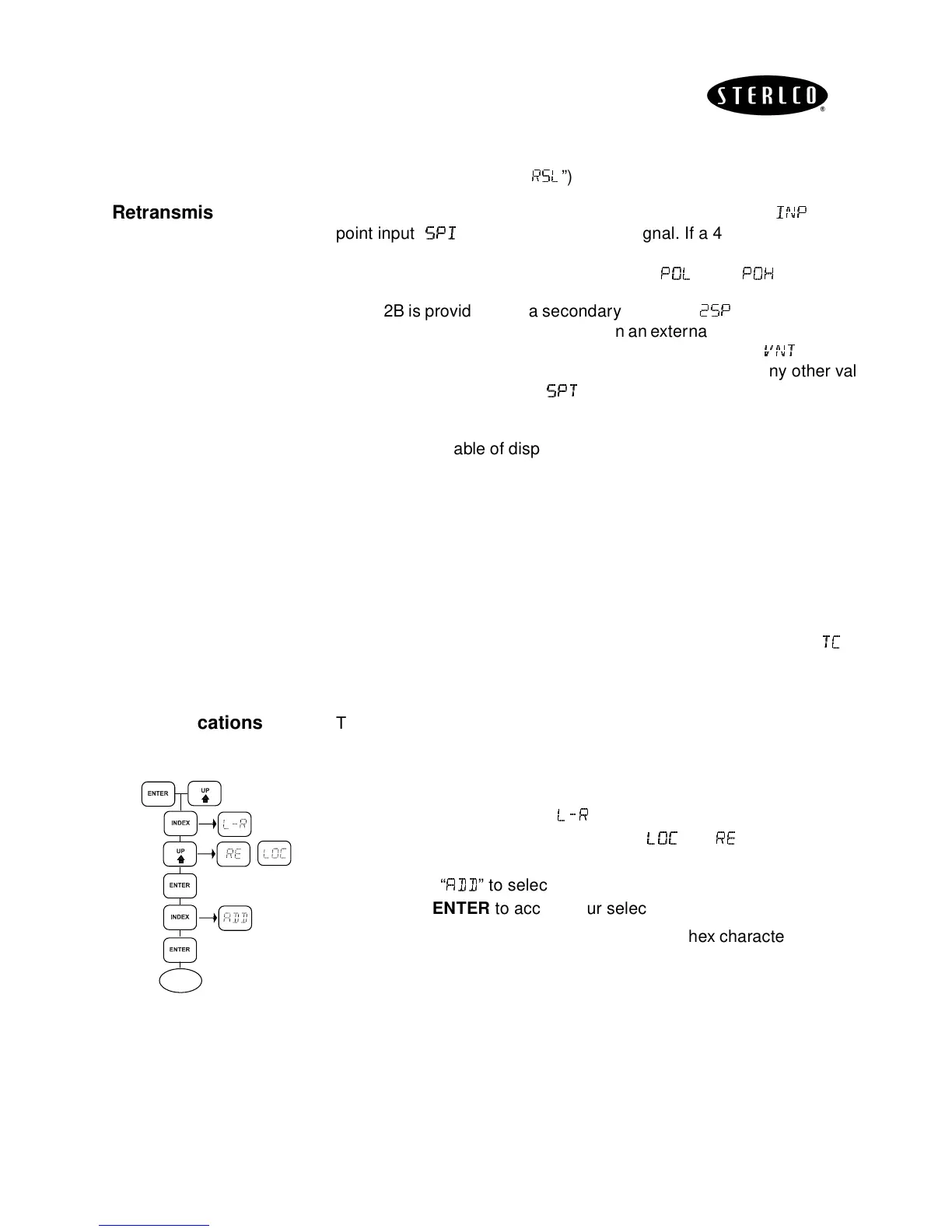

Communications

The Sterling M2B controller can communicate with a host machine via a

half or full duplex RS232 or RS485 communication link.

• Press and hold the

UP

and

ENTER

keys to access the secondary

menu.

• Use the

INDEX

key until “

+

++

+

” appears.

• Use the

UP

or

DOWN

keys to select “

” or “

”

.

• Depress

ENTER

to accept your selection.

•

INDEX

to “

” to select the controller address “1 to 3FF”.

• Depress

ENTER

to accept your selection.

Note

: All data is sent and received in the ASCII hex character format, using

10 bits: 1 Start bit, 8 data bits, no parity and 1 Stop bit.

Any changes in the communication protocol should be made by qualified

technicians.

Host

will be used to describe the computer operating as the originator of

communications.

Instrument

will be used to describe the process

control(2) using this protocol. In the following examples, only

Host

and

Instrument

will be used.

P

S

S

S

RUN

Loading...

Loading...