stewmac.com

22

Raise the grain by damp sanding

Sandpaper cuts away the fuzzy bers of wood grain. Sanding

causes some of these bers to lay down at, even though

they haven’t been removed. When wet nish touches them,

the bers lift up and make your nish feel rough.

Solve this problem by raising the grain with a damp rag.

When you’re done with the 180-grit sanding, wipe the wood

with damp rag (not wet. After the wood dries, you’ll feel the

roughness of the raised grain.

Sand with 220-grit

Now move on to sanding with 220-grit, which cuts away

the bers raised by the damp rag. Completely sand the

body and neck.

Examine your work thoroughly for any scratches that may

have been left by the 180-grit sand paper.

Once you’re satised you’ve removed all the scratches and

everything is smooth, the wood is ready for nish.

However, before nishing, you will need to establish the

bridge location in order to tape o the area where it will

be glued later.

Sand the body and neck

Sand with 180-grit

Sand the body using 180-grit sandpaper and a at sanding

block. Make your sanding strokes with the grain direction,

not sideways across it. You’re looking for and removing any

scratches deeper than the grain itself, and a sideways or

circular motion will create small new scratches.

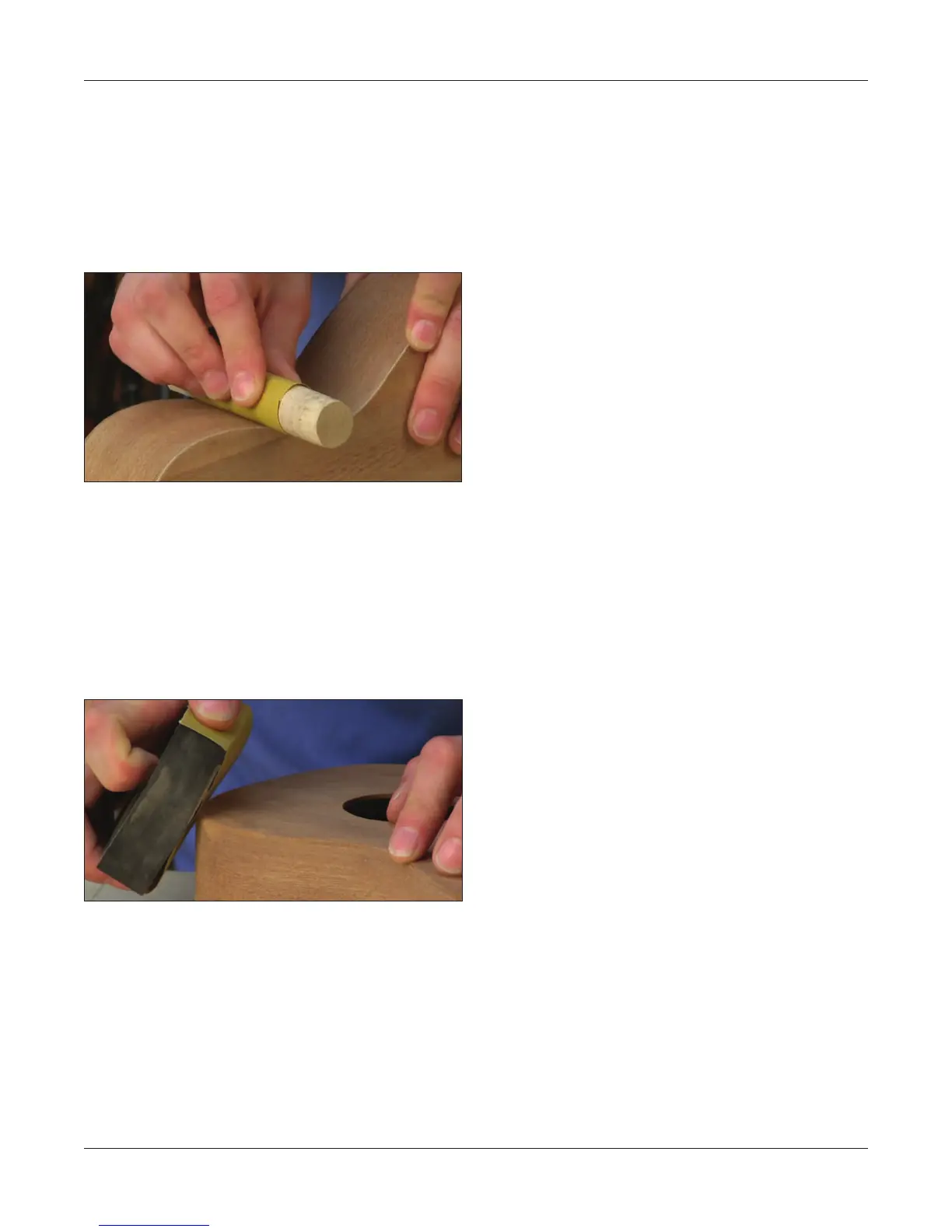

A stout wooden dowel makes a good sanding block for the

inner curves at the waist.

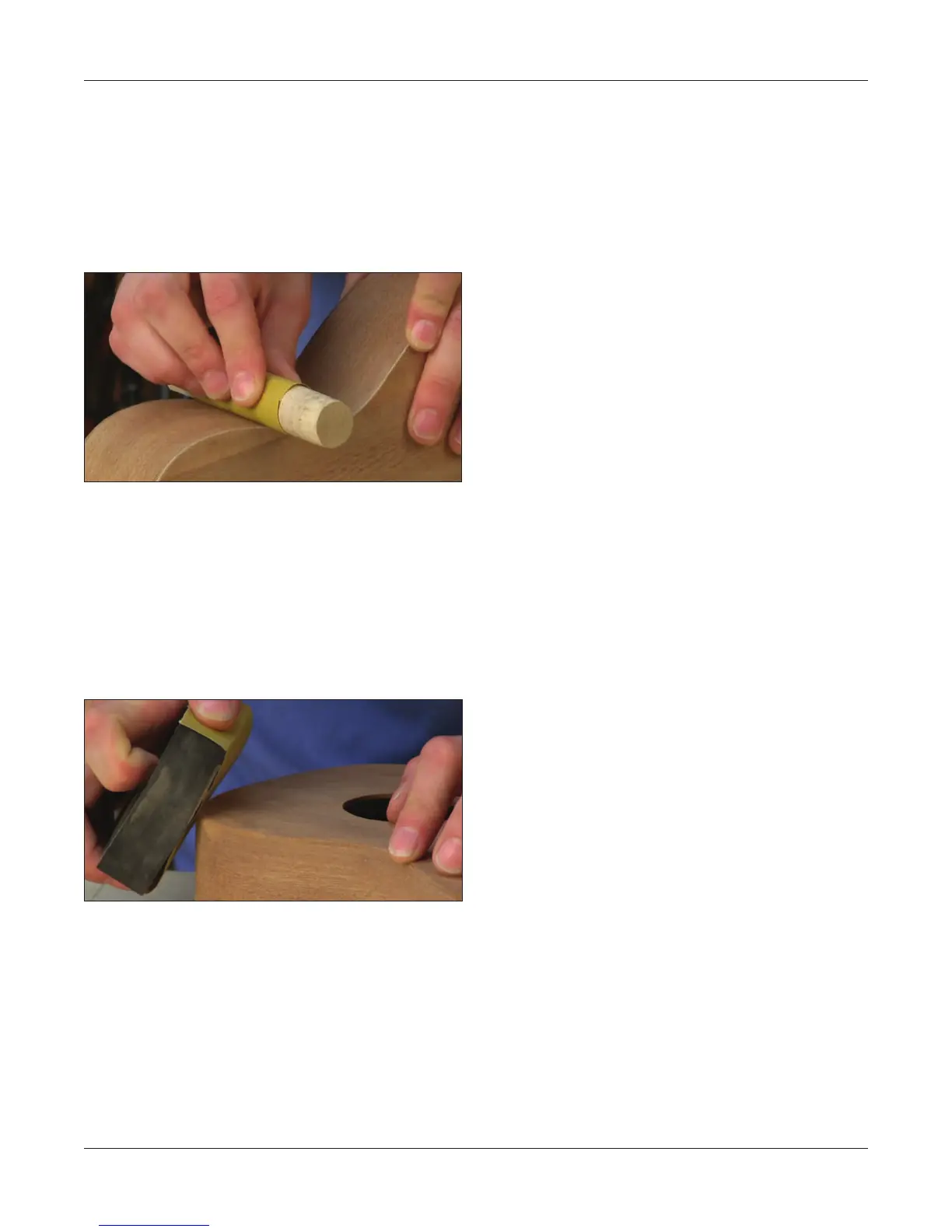

Other than the top edge directly under the ngerboard,

smooth all sharp edges to make them slightly rounded.

When edges are too sharp, it’s easy to accidentally sand the

nish away at those points when you sand between coats.

Knock o all sharp edges so they receive and hold a good

coat of nish.

Carefully examine your work using glancing light to nd

any scratches you missed. Continue with the process until

all deep scratches are removed.

Loading...

Loading...