stewmac.com

7

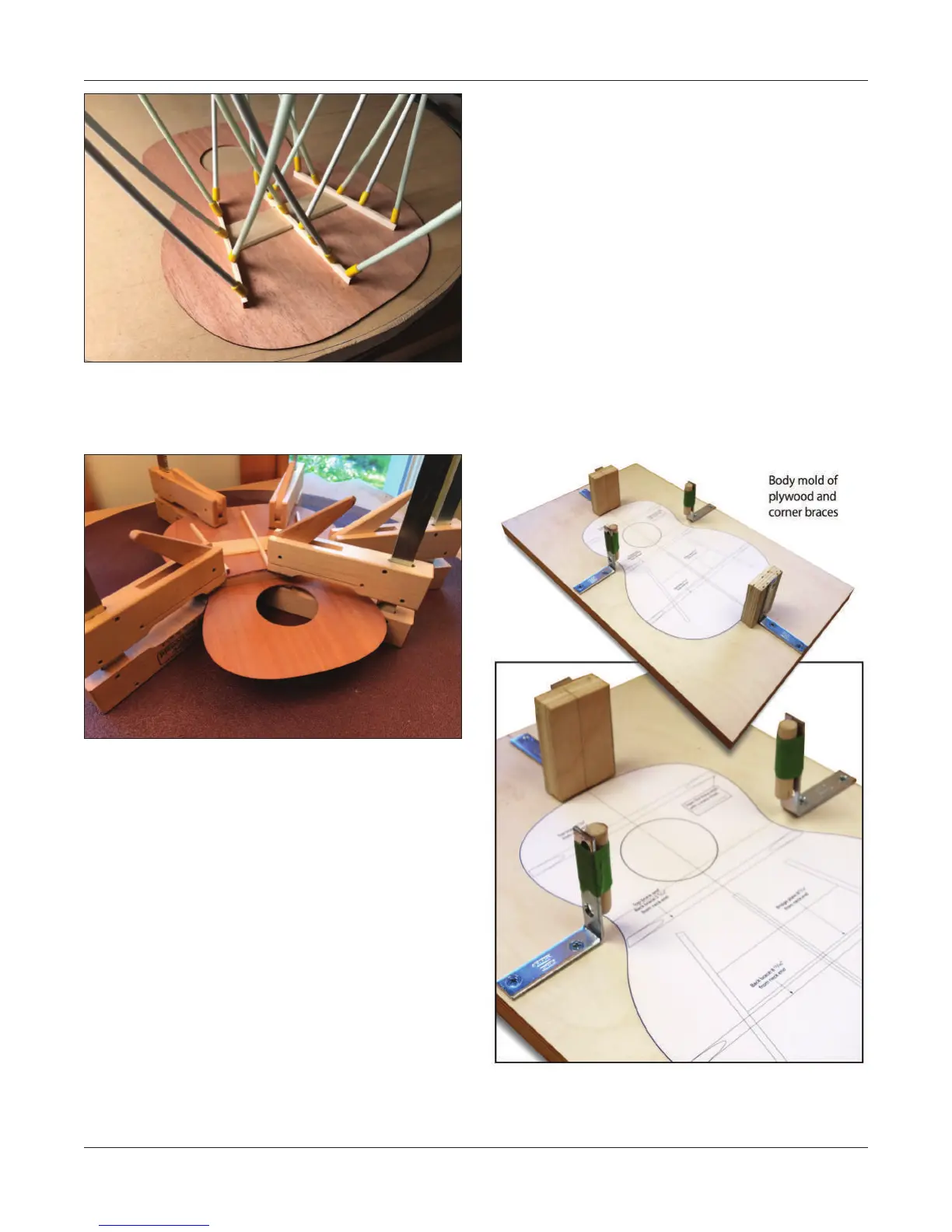

in the photo (below). Screw these two braces to the plywood,

on the centerline. Position them so they are against the bold

line of the uke shape. These are clamp supports for gluing

the neck block and tail block to the sides.

These clamping blocks should be no taller than the sides

of the ukulele.

The other two corner braces support the sides at the uke’s

waist. To avoid metal scarring the mahogany sides, give

these brackets some padding. A piece of dowel wrapped

in masking tape works well.

Screw these braces to the plywood, positioning them against

the uke outline at the waist.

Now we’re ready to begin working on the body.Next glue in the lower transverse brace followed by the

upper transverse brace.

Let the braces dry for 2 hours before removing the clamps.

Make the body mold

Now we are going to turn our attention to the ukulele body,

and this begins with creating an outside mold.

This is a very simple xture: a piece of plywood (or MDF) and

four 2-1/2" corner braces (angle brackets). It holds the body

pieces in shape while you build.

Start with a high quality piece of 3/4" plywood (or MDF),

19"x12". Draw a centerline down the middle of the board.

Tape or spray mount the plan drawing to the plywood,

aligning it on the centerline. The bold black line on the plan

drawing is the nal shape of your uke.

Attach blocks of wood to two of the corner braces, as shown

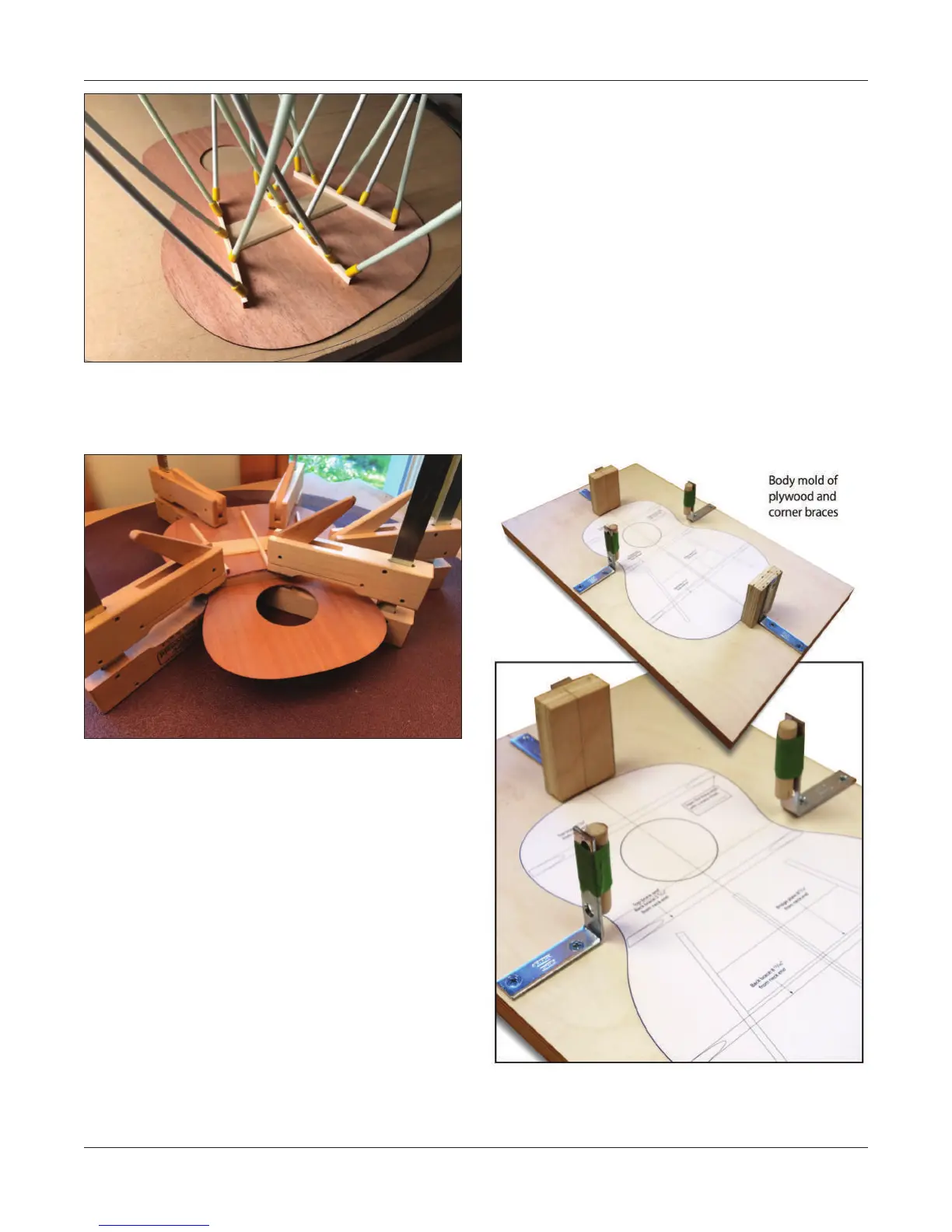

Optional: showing the gluing setup with clamps.

Loading...

Loading...