12 | WPL basic | WPL S basic www.stiebel-eltron.com

INSTALLATION

Mounting

Note

Suitable appliances for water softening and desalinating,

as well as for charging and flushing heating systems, can

be obtained via trade suppliers.

Note

If you treat the fill water with inhibitors or additives, the

same limits as for desalination apply.

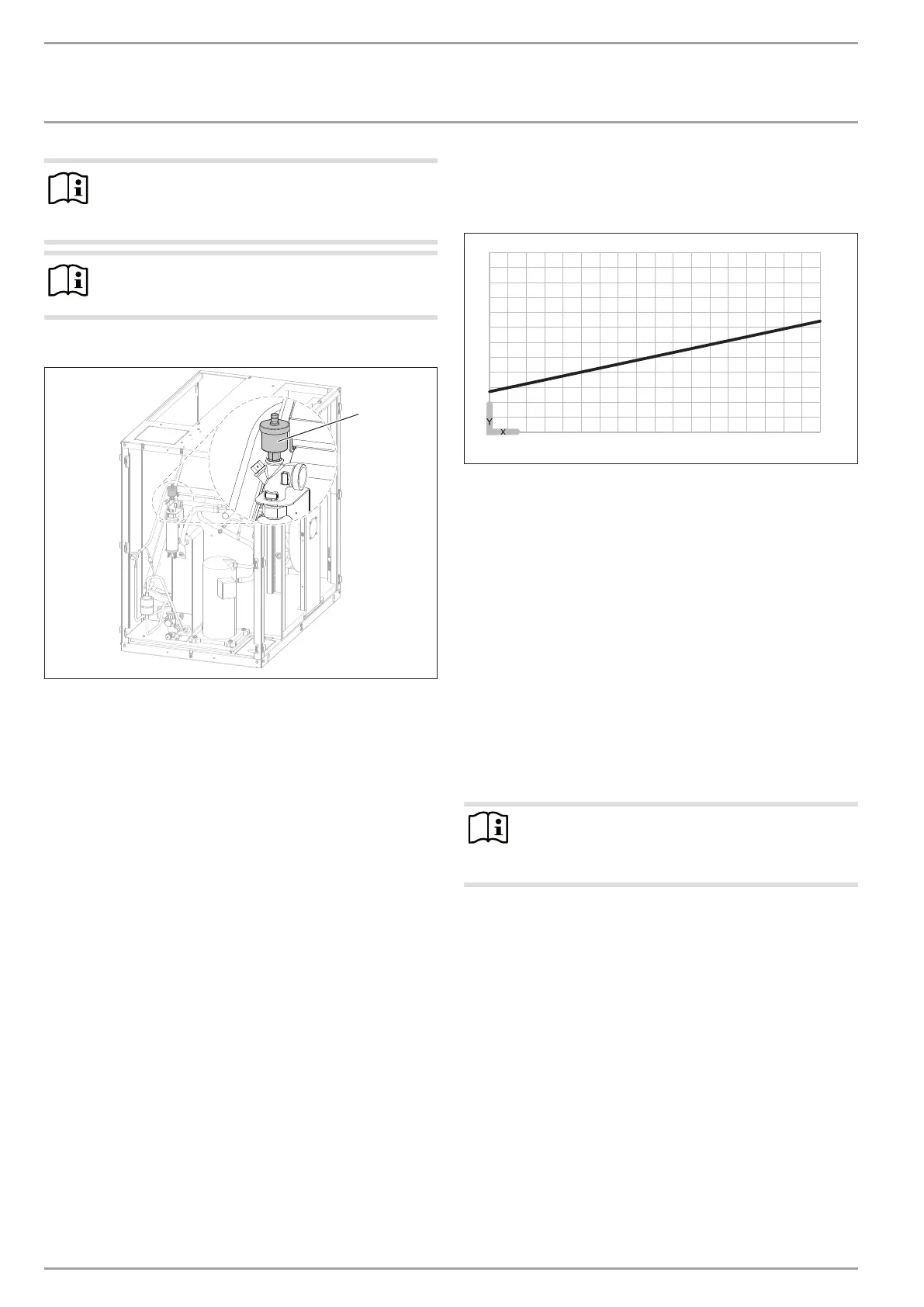

Venting the heating system

1

26�03�01�1638�

1 Air vent valve

Vent the pipework carefully. For this, also activate the air

vent valve integrated into the heating flow inside the heat

pump.

10.4 Flow rate, heating side

10.4.1 Minimum flow rate for operation without a buffer

cylinder

The appliance is designed in such a way that no buffer cylinder

is required to provide hydraulic separation of the flow in the heat

pump circuit and the heating circuit in conjunction with space

heating systems.

In an installation with several heating circuits, we recommend

using a low loss header.

The minimum flow rate is set via the temperature differential of

the heating system.

Set the heating circuit pump so that the value is equal to or lower

than the maximum temperature differential.

The setting is made in heat pump operation alone. For this, the

following settings must be carried out first:

Temporarily remove the fuse from the electric emergency/

booster heater to isolate it from the power supply. Alterna-

tively, switch OFF the second heat source.

Operate the heat pump in heating mode.

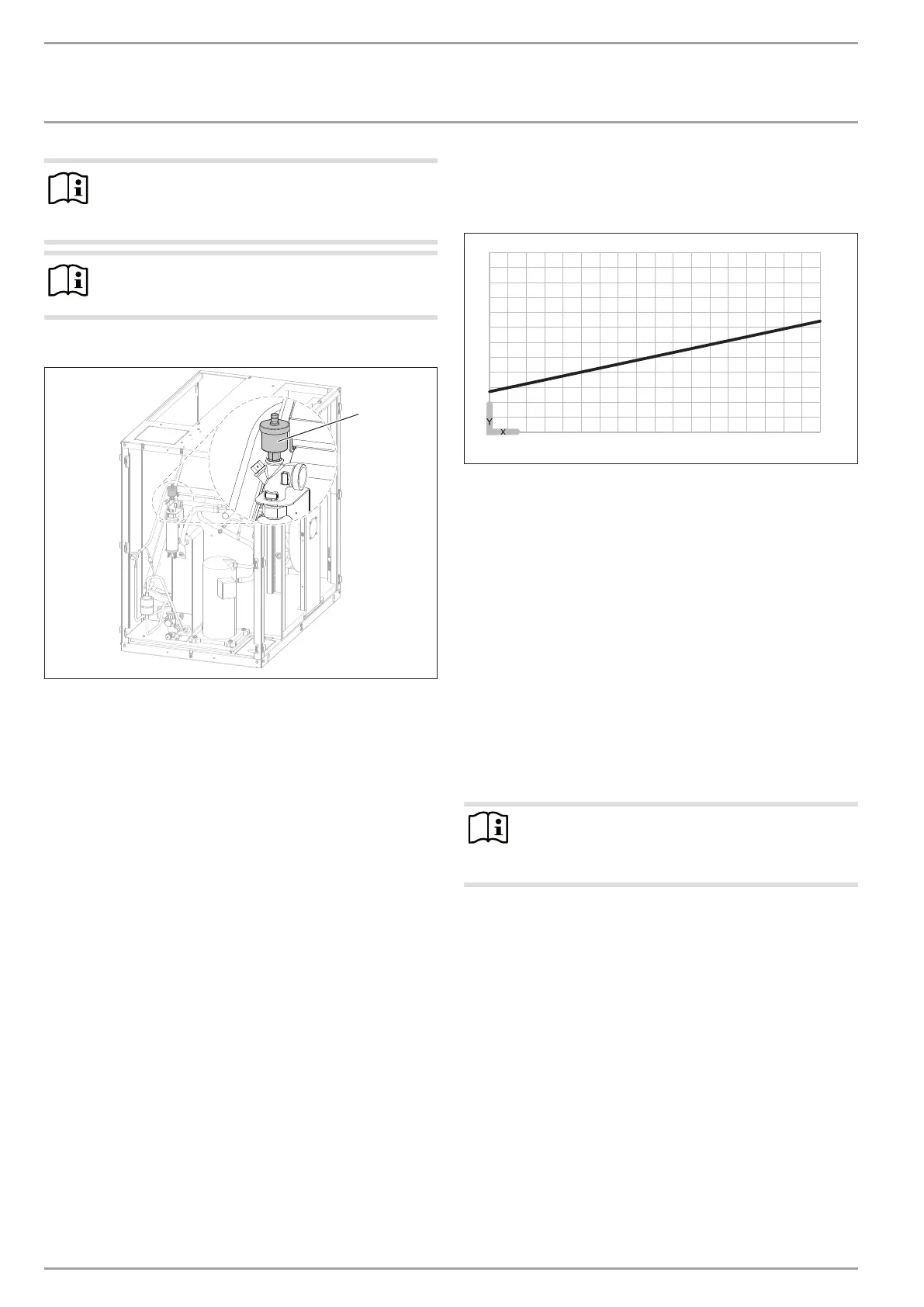

Minimum flow rate with single room control via FE7orFEK

Maximum temperature differential on the heating side with over-

flow valve or single room control with remote control

-15 -10 -5 0 5 10 15 20 25 30

0

2

4

6

8

10

12

84�03�01�0172

X Outside temperature [°C]

Y Maximum temperature differential [K]

In this case, one or more heating circuits in the heating system

must be left open. The open heating circuit(s) should be installed

in the lead room (room in which the remote control is installed,

e.g. the living room). Single room control can then be carried

out with the remote control or indirectly by matching the heating

curve.

Fully open the heating circuit(s) in the lead room.

Close all other heating circuits.

If an overflow valve is installed in the heating system, close

this fully before determining the minimum flow rate.

Make the settings at the circulation pump when the tempera-

ture differential between the flow and return temperature

has stabilised.

Set the heating circuit pump so that the minimum flow rate re-

quired to operate the system is safeguarded.

Note

Never adjust the flow rate of the cylinder primary pump.

The flow rate of the cylinder primary pump has been

optimised at the factory.

Compare the resulting temperature differential between the

flow and return at the appliance with the diagram “Maximum

temperature differential on the heating side with overflow

valve or single room control with remote control”.

Set the heating circuit pump so that the value is equal to or

lower than the maximum temperature differential.

Loading...

Loading...