•

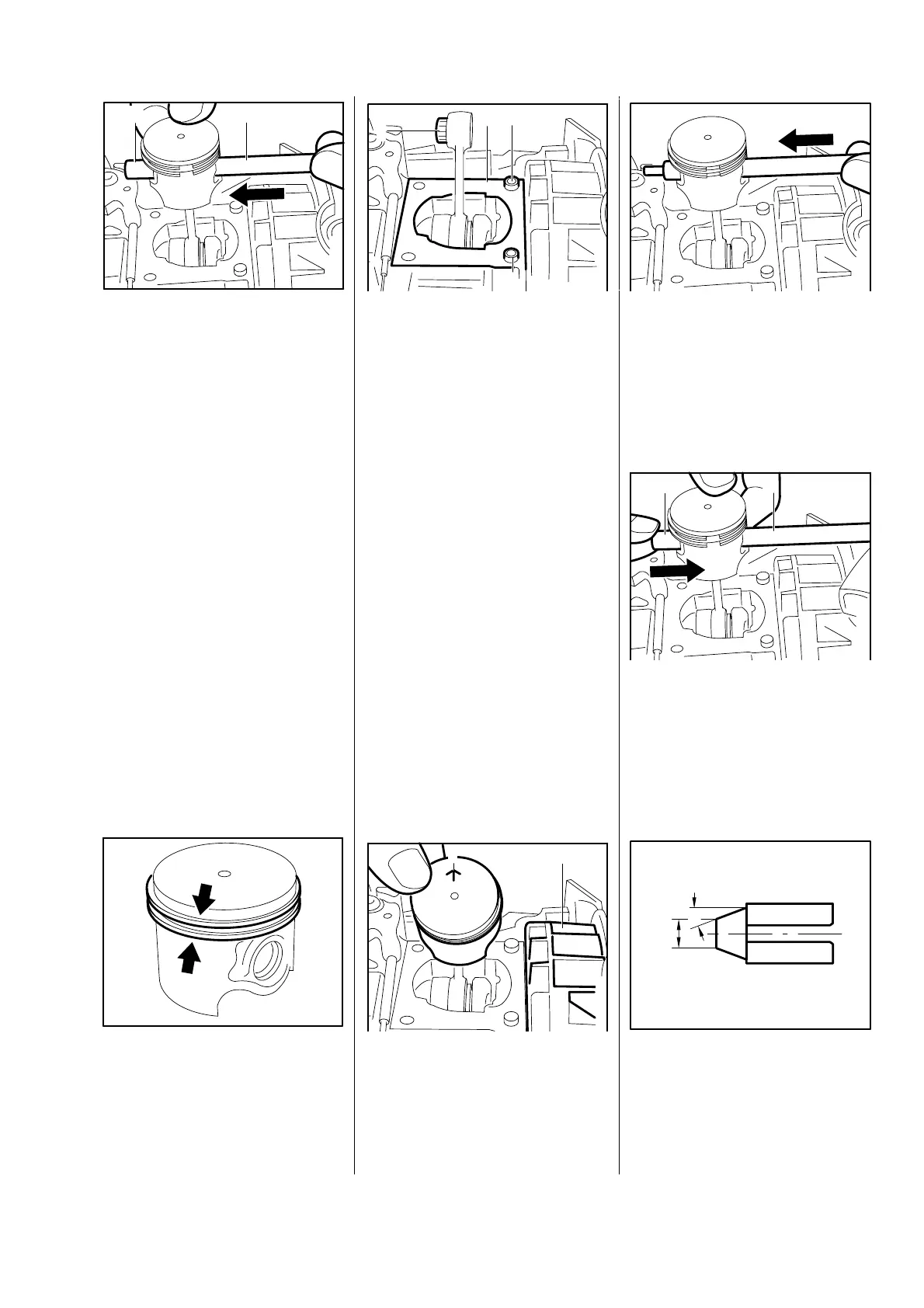

Now use the assembly drift (2)

1110 893 4700 to push the pis-

ton pin (1) out of the piston.

Note: If the piston pin is stuck, tap

the end of the drift lightly with a

hammer if necessary. Hold the

piston steady during this process

to ensure that no jolts are trans-

mitted to the connecting rod.

Remove piston and take the

needle cage out of the connect-

ing rod.

•

Inspect piston rings and replace

if necessary - see 4.6.

•

Thoroughly clean the gasket

seating surface (1).

•

Check that adapter sleeves (2)

are in place. Fit them if necess-

ary.

•

Lubricate the needle cage (3)

with oil and fit it in the connecting

rod.

•

To simplify assembly, heat the

piston and slip it over the con-

necting rod.

•

Installed position of piston:

1 = Marking

2 = Flywheel

•

Push the assembly drift, small

diameter first, through the piston

and small end (needle cage) and

line up the piston.

•

Fit the piston pin (1) on the

assembly drift (2) and slide it

into the piston (the pin slides

home easily if the piston is hot).

•

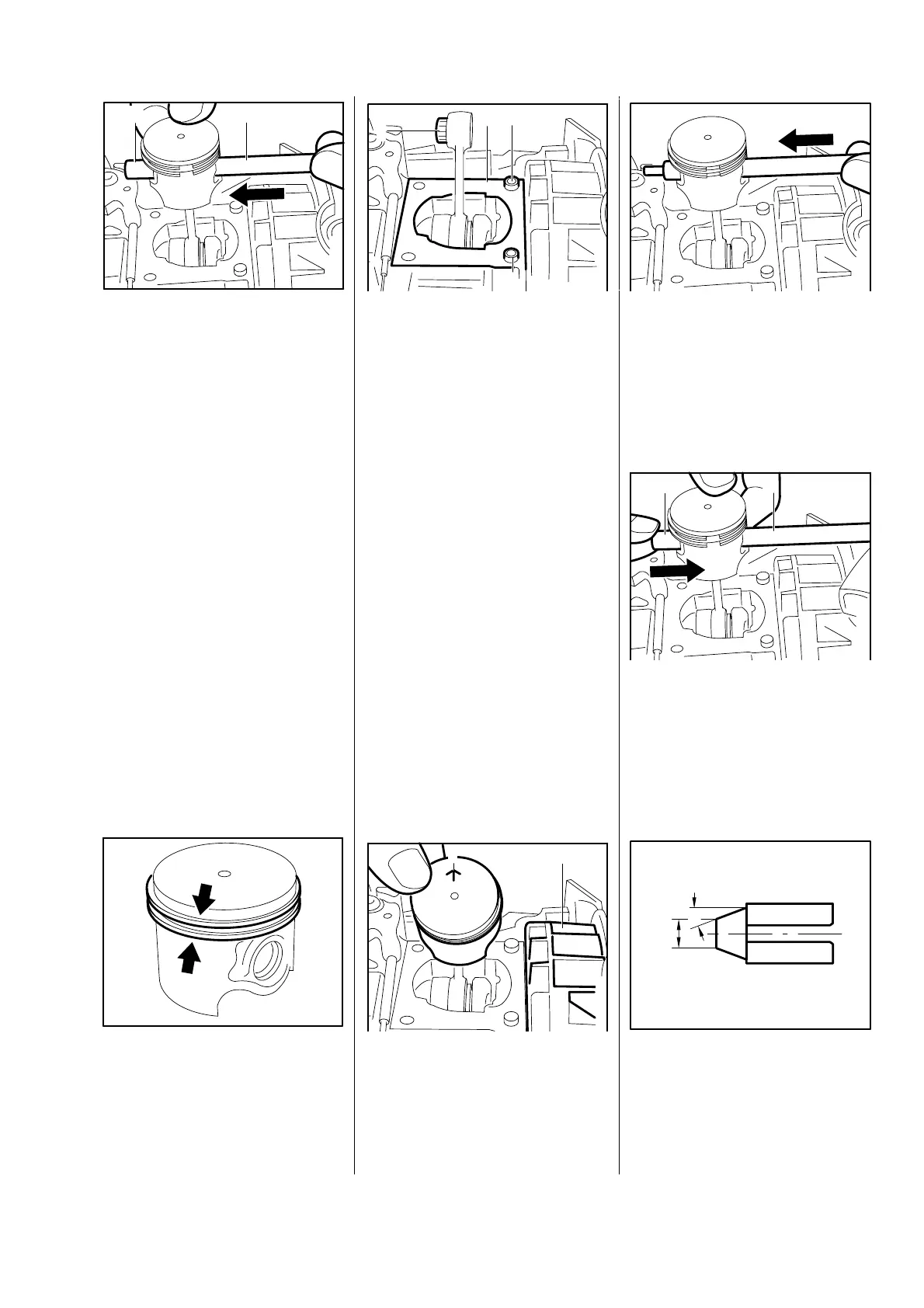

Modify sleeve of installing tool

5910 890 2210 as shown in

drawing.

a = 30 degrees

b = Ø 10 mm

250RA033

1 2

VA

250RA035

1 2

2

3

VA

250RA037

21

VA

250RA034

VA

250RA038

VA

250RA039

1 2

VA

250RA057

b

a

VA

4.5.2 Installation

)6)5

Loading...

Loading...