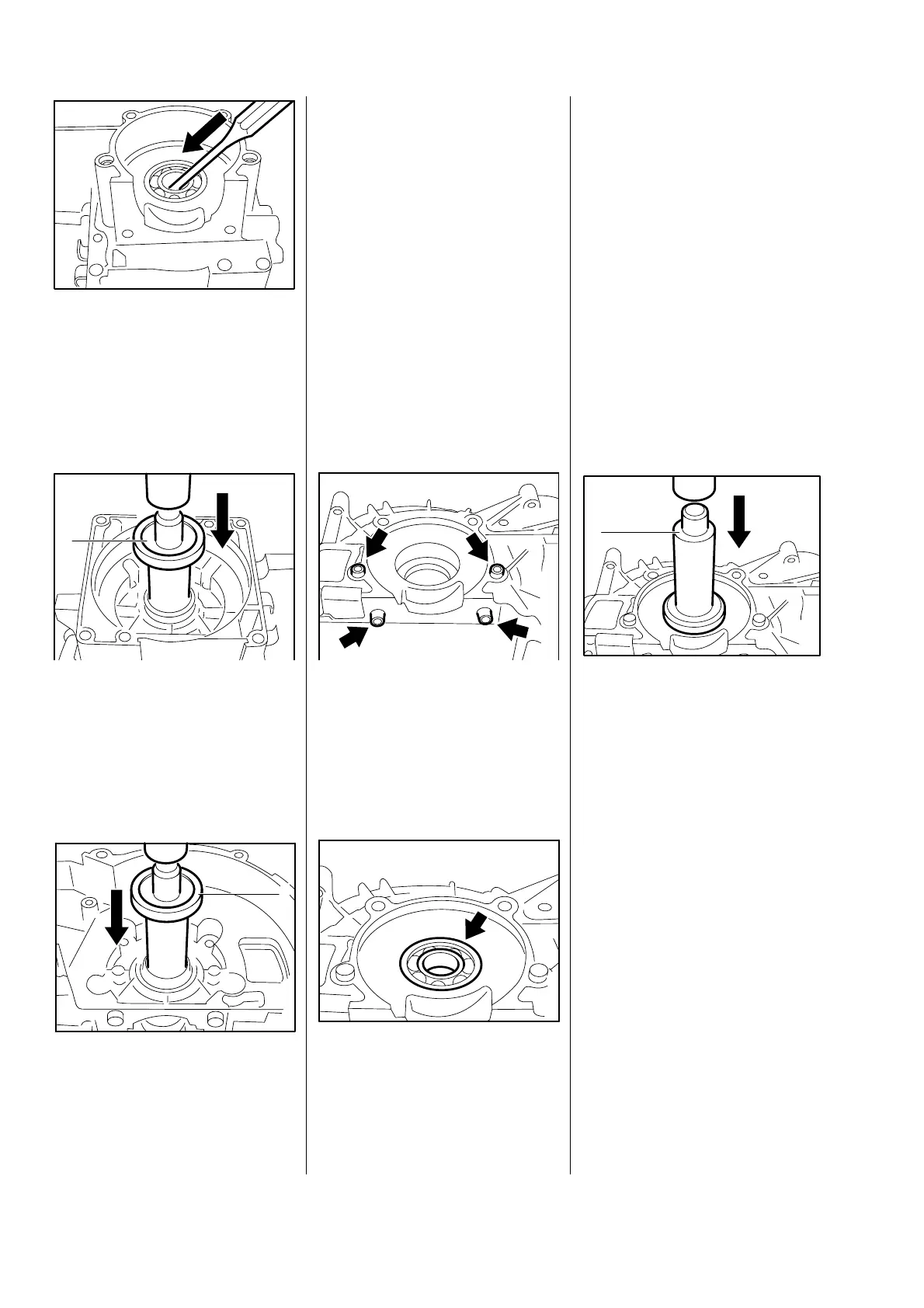

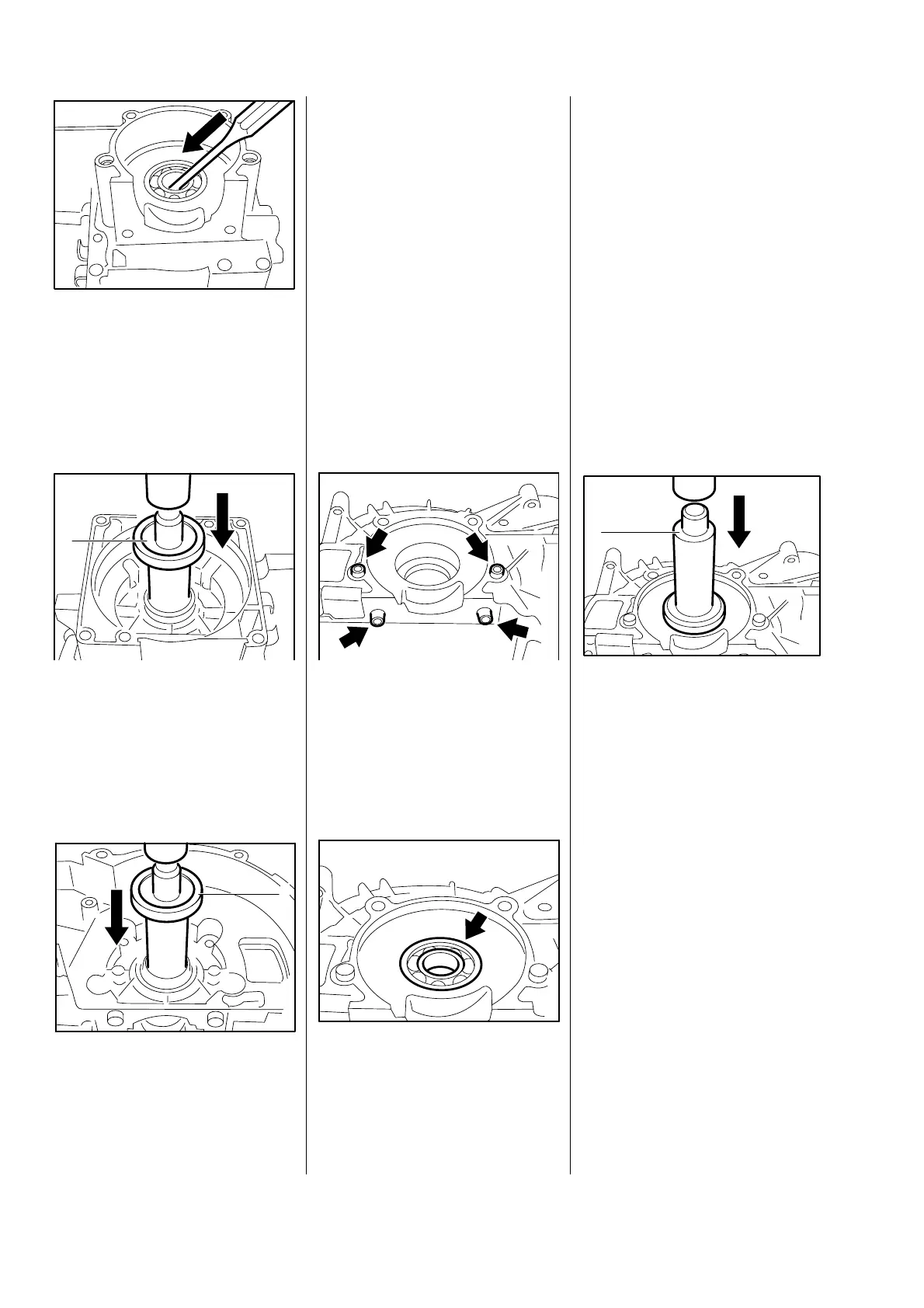

When fitting a replacement crank-

shaft always install new oil seals

and ball bearings.

•

Carefully knock the oil seals out

of the crankshaft.

•

Use press arbor (1) 4119 893

7200 to remove ball bearing.

•

Use press arbor (1) 4119 893

7200 to remove ball bearing.

Inspect both halves of the crank-

case for cracks and replace if

necessary.

Each half of the crankcase may

be replaced separately.

New crankcases come with

factory-installed ball bearings.

If the original crankcase is used

again, remove the gasket residue

and clean the mating surfaces -

they must be cleaned very

thoroughly to ensure a perfect

seal.

•

Check that bushings are in posi-

tion. If necessary, drive bushings

into the crankcase.

Heat area of bearing seat on

starter side of crankcase to

approx. 120°C (250°F).

•

Fit ball bearing in crankcase by

hand and push it home as far as

stop.

Note: This operation must be

carried out very quickly because

the bearing absorbs heat immedi-

ately and begins to expand.

•

If it is not possible to heat the

starter side of the crankcase,

use press arbor (1) 4119 893

7200 to press in the ball bearing

as far as stop.

Heat area of bearing seat on

clutch side of crankcase to

approx. 120°C (250°F).

250RA067

VA

250RA068

1

VA

250RA069

VA

1

250RA071

VA

250RA070

VA

250RA072

1

VA

4.7.2 Installing Crankshaft

)6)5

Loading...

Loading...