•

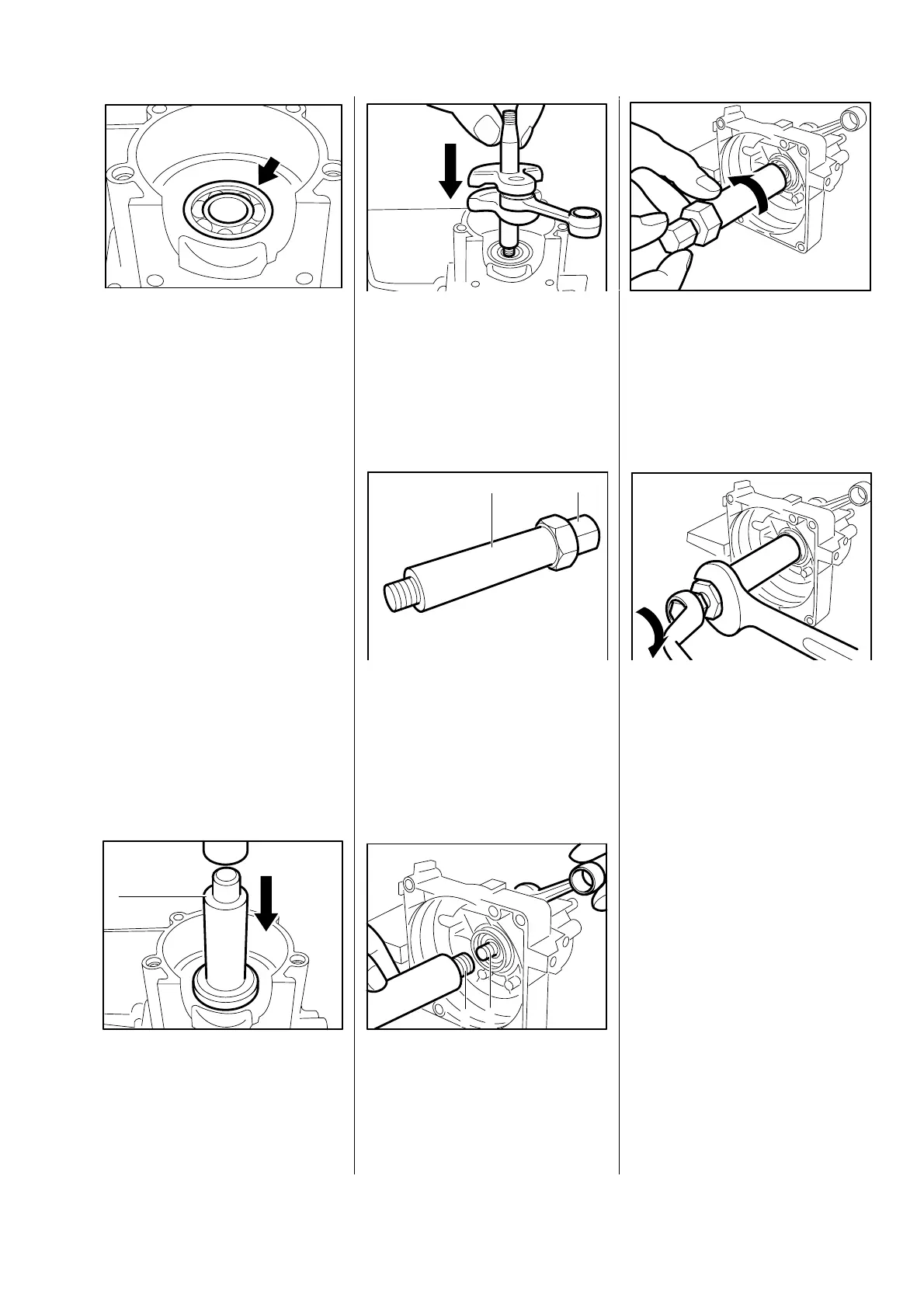

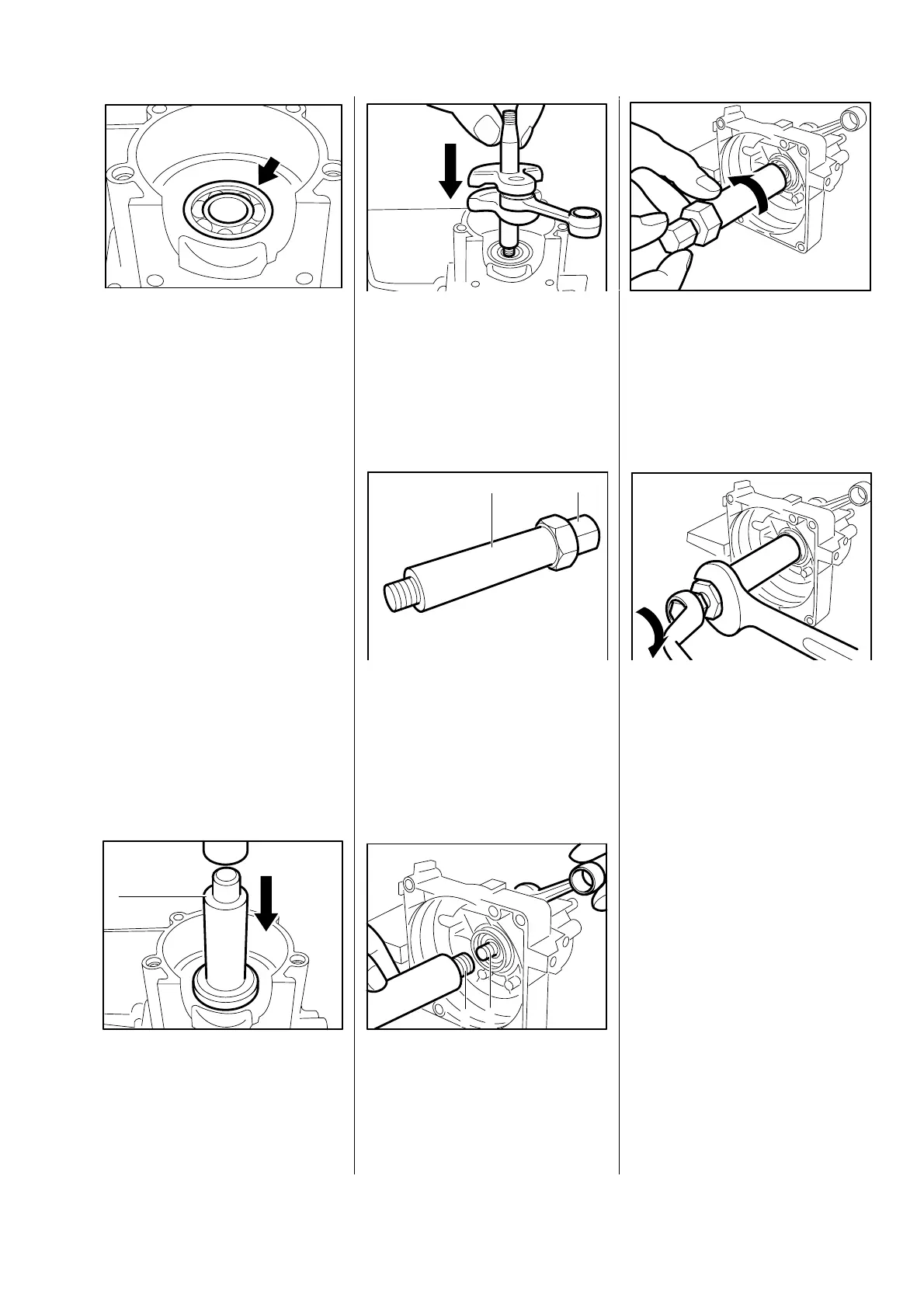

Fit ball bearing in crankcase by

hand and push it home as far as

stop.

Note: This operation must be

carried out very quickly because

the bearing absorbs heat immedi-

ately and begins to expand.

•

If it is not possible to heat the

clutch side of the crankcase, use

press arbor (1) 4119 893 7200 to

press in the ball bearing as far

as stop.

•

Position the straight stub of the

crankshaft in the bearing at the

clutch side of the crankcase.

•

Screw spindle (1) of installing

tool 5910 890 2202 fully into the

sleeve (2) (left-hand thread).

•

Hold the crankshaft steady and

screw the spindle (1) clockwise

onto the stub (2) as far as stop.

•

Hold the spindle steady and

rotate sleeve counterclockwise

until it butts against the ball

bearing.

•

Hold the sleeve steady and

rotate spindle clockwise until the

crankshaft butts against the ball

bearing.

Important: During this process the

connecting rod (without

piston) must point towards the

cylinder flange.

Hold the crankshaft steady and

unscrew spindle from the stub.

Apply a thin coating of sealant to

crankcase mating face - see

13.2.

Important: Follow manufacturer’s

instructions.

250RA073

VA

250RA077

VA

250RA075

VA

392RA044

2 1

VA

250RA078

VA

250RA074

1

VA

250RA076

21

VA

)6)5

Loading...

Loading...