EN

English–15

5.1-Programmingwarnings

•Ingeneral

-Strictlyobservethetimelimitsspeciedintheprocedures.

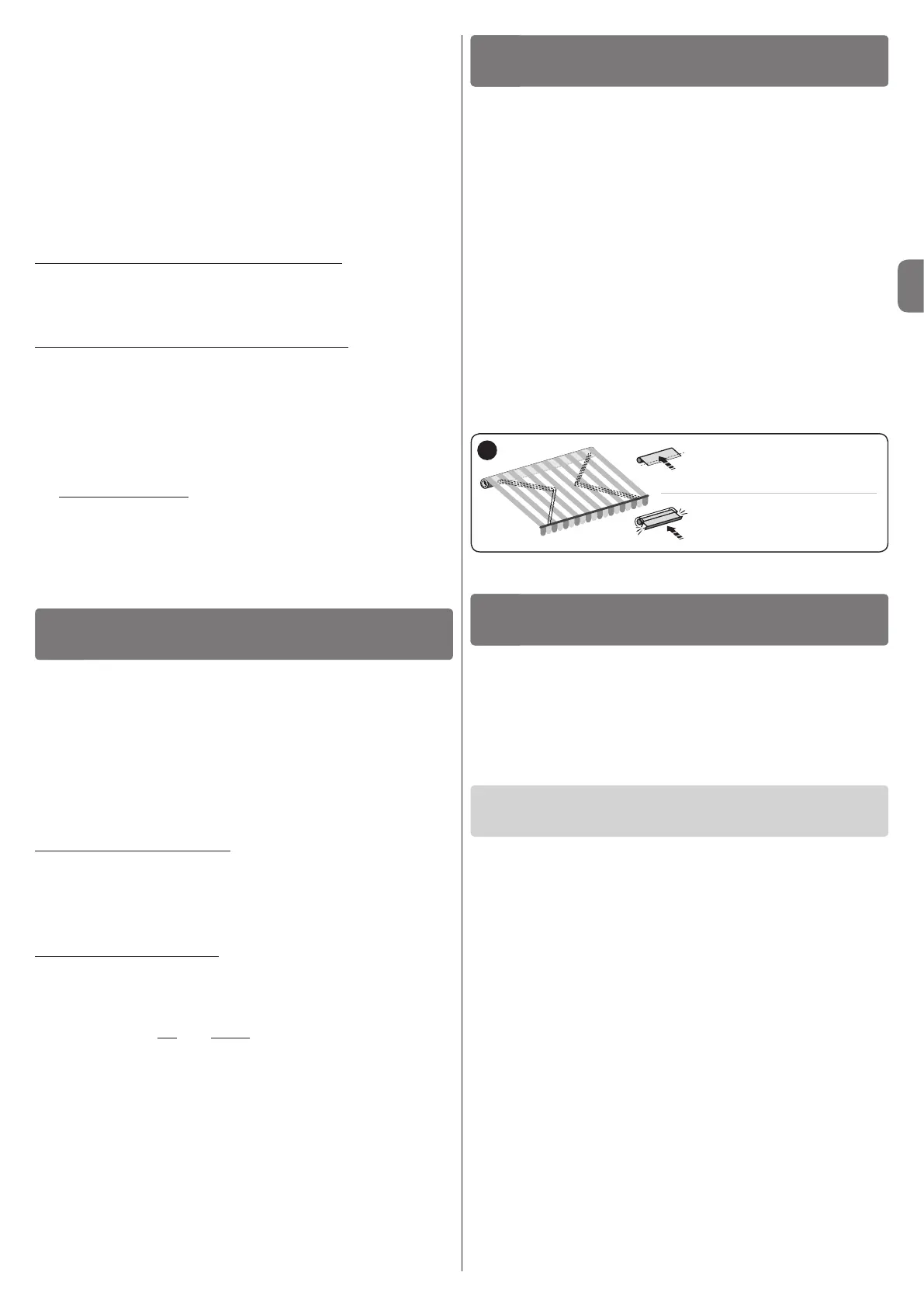

-Positions0,1oftheawning,speciedinthetext,correspondtothoseillustratedin

fig. 14.

-Duringinstallationandadjustment,whilenalelectricalconnectionsarestilltobe

made,thesystemcanbecontrolledwiththespecic“MA2001/MA2002”unit

(fig.15).

5.2-Limitswitchprogramming

Limitswitches“0”and“1”(fig. 14)correspondtothepositionsoftheawningatthe

endoftheUpmovements(“0”)andtheendoftheDownmovements(“1”).

Toselecttheproceduremostsuitedtothesystemfeatures,refertofig. 17.

5.3-Noteon“RDC”function

TheRDCfunctionpreventsthecanvasfromremainingexcessivelytensionedatthe

endoftheclosingmanoeuvre.Thefunctionautomaticallyreducesthemotortraction

torqueduringthenalphaseoftheclosingmanoeuvre(tosettherequiredtorque

value,refertoparagraph5.6).

Thisfunctionisenabledbydefault,butwillnotworkifthelimitswitchesarepro-

grammedusingthemanualprocedure(paragraph5.4).

Caution!

-Incorrectconnectionscancausefaultsorhazardoussituations.

-Strictlyobservetheconnectionsspeciedinthismanual.

-Adisconnectdevicemustbeinstalledontheproductpowersupplyline,withagap

betweencontactstoensurecompletedisconnectioninovervoltagecategoryIII,in

compliancewithinstallationregulations(thedisconnectdeviceisnotsuppliedwith

theproduct).

Tomaketheelectricalconnections,refertothewiringdiagraminfig. 11.Thedia-

gramshowstheconnectionbetweenthetwomotors,connectionofacontrolpush-

buttonpanel,connectiontothemainsandconnectiontoaswitchfordisconnection

fromthemains.Thefollowingtableshowsthepurposeofeachwire.

“MASTER”motorcable–6wires:

1 - Yellow-green:=System“earth”(equipotentialbondingconnection).

2 - Blue:=System“Common”(usuallyconnectedtoNeutral).

3 - Brown:=systemelectricalascent(ordescent)phase.

4 - Black:=systemelectricaldescent(orascent)phase.

5 - Violet:=“slave”motorelectricalascent(ordescent)phase.

6 - Red:=“slave”motorelectricaldescent(orascent)phase.

“SLAVE”motorcable–4wires:

7 - Violet:=“slave”motorelectricalascent(ordescent)phase.

8 - Red:=“slave”motorelectricaldescent(orascent)phase.

9 - Blue:=“Common”(usuallyconnectedtoNeutral).

10 - Yellow-green:=“Earth”(equipotentialbondingconnection).

•AssociatingtheUpandDownmovementswiththerespec-

tivepushbuttons

Aftermakingtheconnections,runanumberofmanoeuvres(*)toensurethatthe

ascentanddescentmovementsareassociatedcorrectlywiththerespectivecontrol

buttons.Ifthisisnotso,inverttheconnectionoftheBrownandBlackwires.

ELECTRICALCONNECTIONS

4

PROGRAMMING

5

Whattodoif…

(troubleshooting guide)

6.1-Maximumcontinuousworkcycle

Ingeneralthetubularmotors,whileguaranteeingamaximumcontinuoususeof

4minutes,aredesignedforresidentialapplicationsandthereforefordiscontinu-

oususe.Thereforeintheeventofoverheating(forexampleduetocontinuousand

prolongedactivation)athermalcut-outtripsautomaticallytoshutoffpowersupply.

Powerisonlyrestoredwhenthetemperaturereturnstowithinthenormalrange.

WARNINGSFORDAILYUSEOF

THEAUTOMATION

6

q When an electrical phase is powered up, the system does not move:

Providedthatathermalcut-outhasnottripped,inwhichcaseitissufcientto

waitforthesystemtocooldown,performthefollowingchecks.

•Ensurethatthemainsvoltagecorrespondstothedatastatedinthetechnical

specicationsofthismanual,measuringthevoltagebetweenthe“common”wire

andthatofthepoweredelectricalphase.

•Checktheconnectionbetweenthetwomotorsandthemains.

•Lastly,trypoweringuptheoppositetheelectricalphase.

q When a command is sent, the system seems to start (a noise can be heard)

but fails:

•Checktheconnectionbetweenthetwomotorsandthemains.

•Athermalcut-outononeofthetwomotorsmayhavetripped;waitfortherela-

tivemotortocool.

•Ensurethatthedirectionofrotationofthetwomotorsiscoordinatedtoenable

theawningtomoveupanddown.

q The system still runs in emergency conditions, i.e. in hold-to-run condi-

tions:

•Checkwhetherthemotorshavebeensubjecttoanelectricshockorsubstan-

tialmechanicalstress.

•Checkthemechanicalconditionofallmotorparts.

•Runthedeletionprocedure(paragraph5.7)andprogramthelimitpositions

again.

Manual procedure

paragraph5.4

Semi-automatic procedure

paragraph5.5

17

3.3-Otherinstallationwork

3.3.1- Changingthedirectionofthecableoutlet

(onMOVENOTandemZversiononly)

Tochangethedirectionofthecableoutlet,refertofig. 6:

01. Pulltheprotectioncoverinthedirectionofthearrowtoremove.

02. Bendthecableintherequireddirection.

03. Re-ttheprotectioncoverbypressingitrmlyintoitsseat.

3.3.2- Replacingadamagedpowercable

(onMOVENOTandemYandMOVENOTandemZversions

only)

Ifthepowercable(orconnector)isdamaged,itmustbereplacedwithanidenticalversion

availablefromSTOBAGTechnicalAssistance.

Replacing the cable on the MOVENO Tandem Y motor (fig. 9):

A.

Turntheringnuttoalignthechamferededgewithoneofthecouplingteeth,then

release.

B. Repeatthesameoperationfortheothertooth.

C. Bendthecableinwardsandremovetheprotectionbyturningitgentlyoutwards.

D. Pulltheconnectorouttoremove.

Replacing the cable on the MOVENO Tandem Z motor (fig. 10):

A.

Pulltheprotectionoutwardstoremove.

B. Pulltheconnectorouttoremove.

3.3.3-Installingthewall-mountedpushbuttonpanel

Installacontrolpushbuttonpanelonthewall,takingcaretoobservethefollowing:

– EachMOVENOTandemsystemcanbeconnectedandcontrolledviaasingle

pushbuttonpanel(fig. 12).Toconnectit,refertofig. 11.Inthecaseofmultiple

systems,theycannotallbecontrolledviathesamepushbuttonpanel(fig. 13).

– Selecta2-buttonpanel(UpandDown).

– Itisadvisabletousea“hold-to-run”pushbuttoncontrolpanel,i.e.itisnecessary

topressandholdthebuttonforthedesireddurationofthemanoeuvre.

– Positionthepushbuttonpanelinsightoftheawningbutfarfrommovingparts.

– Positionthepushbuttonpaneltothesideoftheawning,wherethe“master”tubu-

larmotorpowercableandthemainspowercablearelocated.

– Positionthepushbuttonpanelataheightofatleast1.5mfromtheground.

www.stobag.com

Loading...

Loading...