Electronic Control System

Integrated

Integrated

(700-

(700-

3

3

T

T

ALL)

ALL)

Series

Series

3-12

#3758412 - Revision B - December, 2006

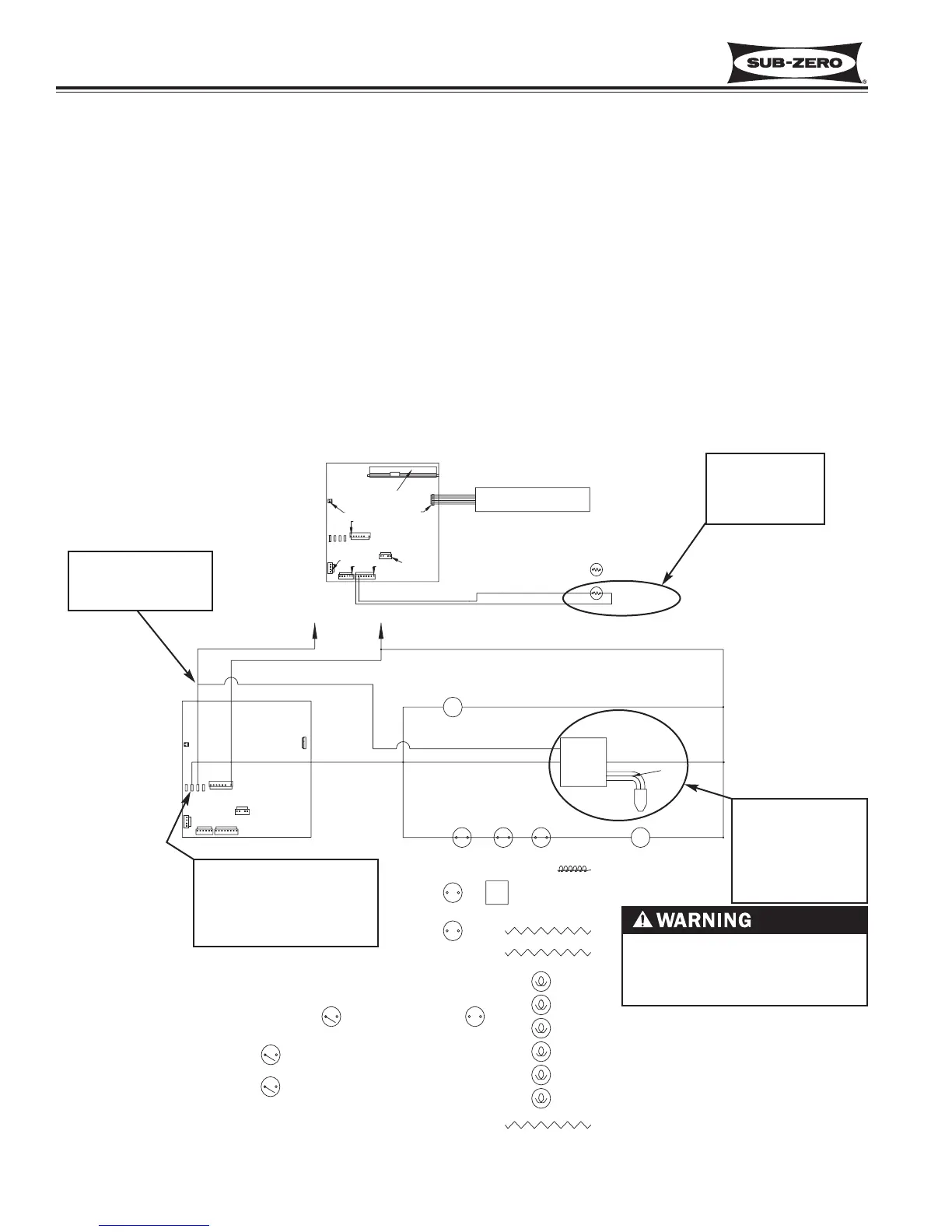

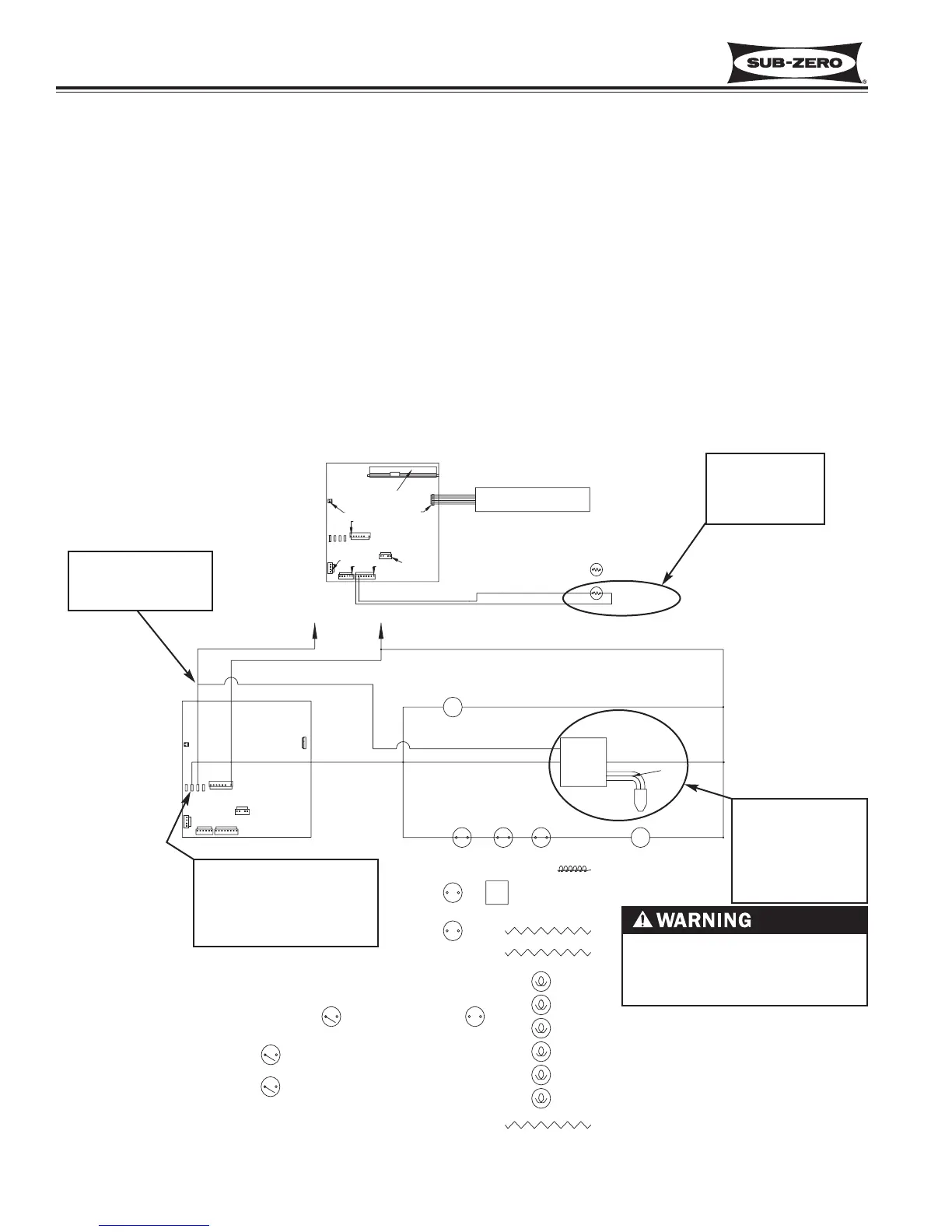

Assist in Control of Variable Speed Compressors (700TF/I-3 Only)

As mentioned on the previous page, temperature signals from the thermistors in the compartment are monitored by

the microprocessor and then displayed on the LCD.

When the compartment reaches high-offset (calling for cooling), an “ON” signal is sent from the control board to the

compressor’s inverter. The inverter (which is supplied with AC power at all times) then provide high DC voltage (3-

phase, 50 - 150 Hz), outputs to the compressor. The inverter in turn senses the compressor load. If the compressor

load is high, the speed command from the inverter will be for high speed compressor operation; if medium compres-

sor load, speed command from the inverter will be for medium speed; if low compressor load, speed command from

the inverter will be for low speed. If/when the compartment reaches low-offset, an “OFF” signal is sent to the invert-

er, which then cuts DC power to the compressor.

NOTE:

• The variable speed compressor, evaporator fan and the condenser fan will run a great majority of the time. This is

normal. These components will only cycle off during defrost and may also cycle off for short periods of time if the

ambient temperature is low enough.

• Initial speed command from an inverter to a compressor are always for High speed.

LT. BLUE

Figure 3-21. 700TF/I-3 Signal Trace Schematic of Variable Speed Compressor Operation

IN EXCESS OF 200 VOLTS MAY

BE PRESENT AT INVERTER

AND COMPRESSOR!

1. Compartment

temperature

monitored by

microprocessor

3. Inverter supplies

high DC voltage,

3-phase, 50 - 150

Hz signal, based

on compressor

load.

2. When cooling is called for,

115 Volts AC “ON” signal

supplied to compressor

inverter, evaporator fan

and condenser fan.

NOTE: Line voltage

supplied to inverter

at all times.

Loading...

Loading...