Section 2

DESCRIPTION

10

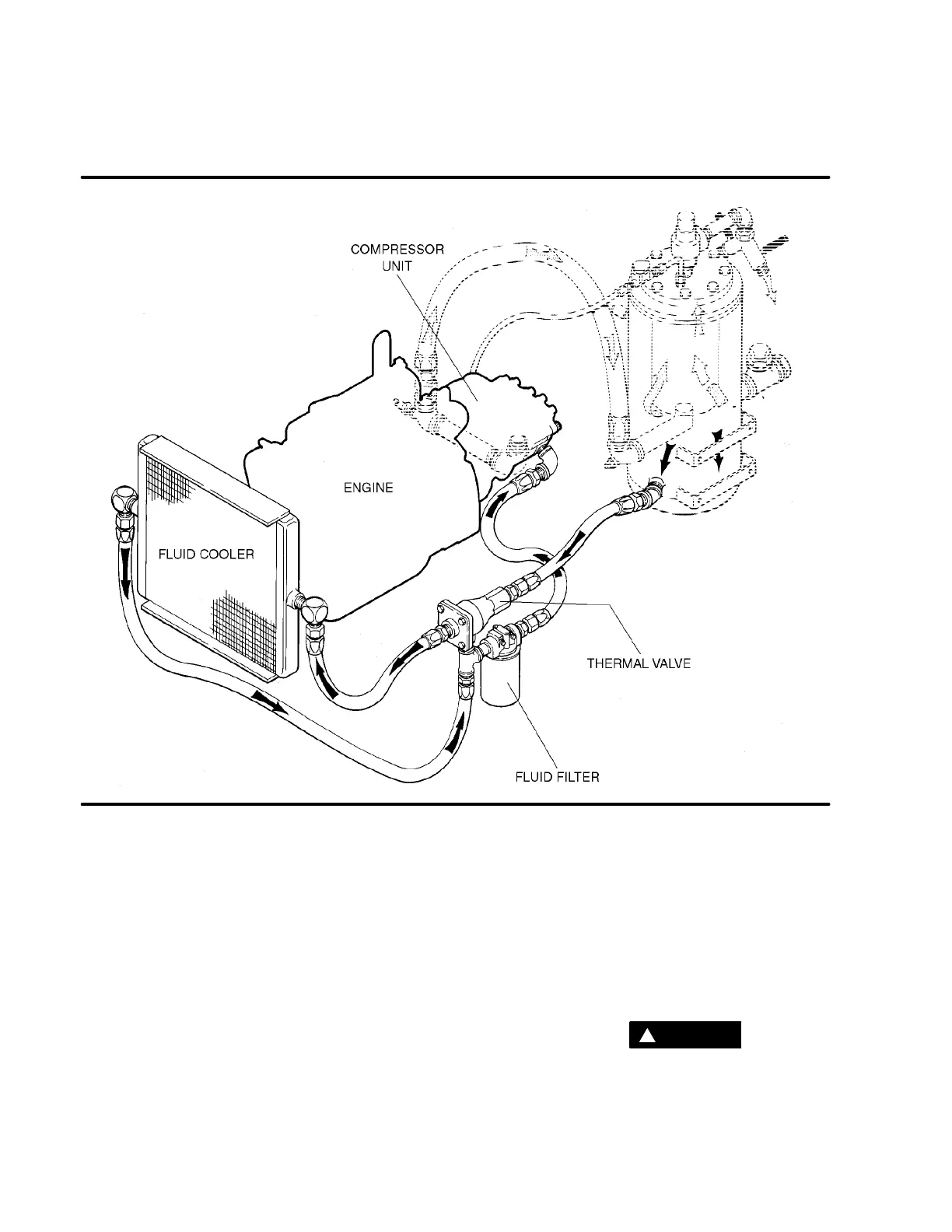

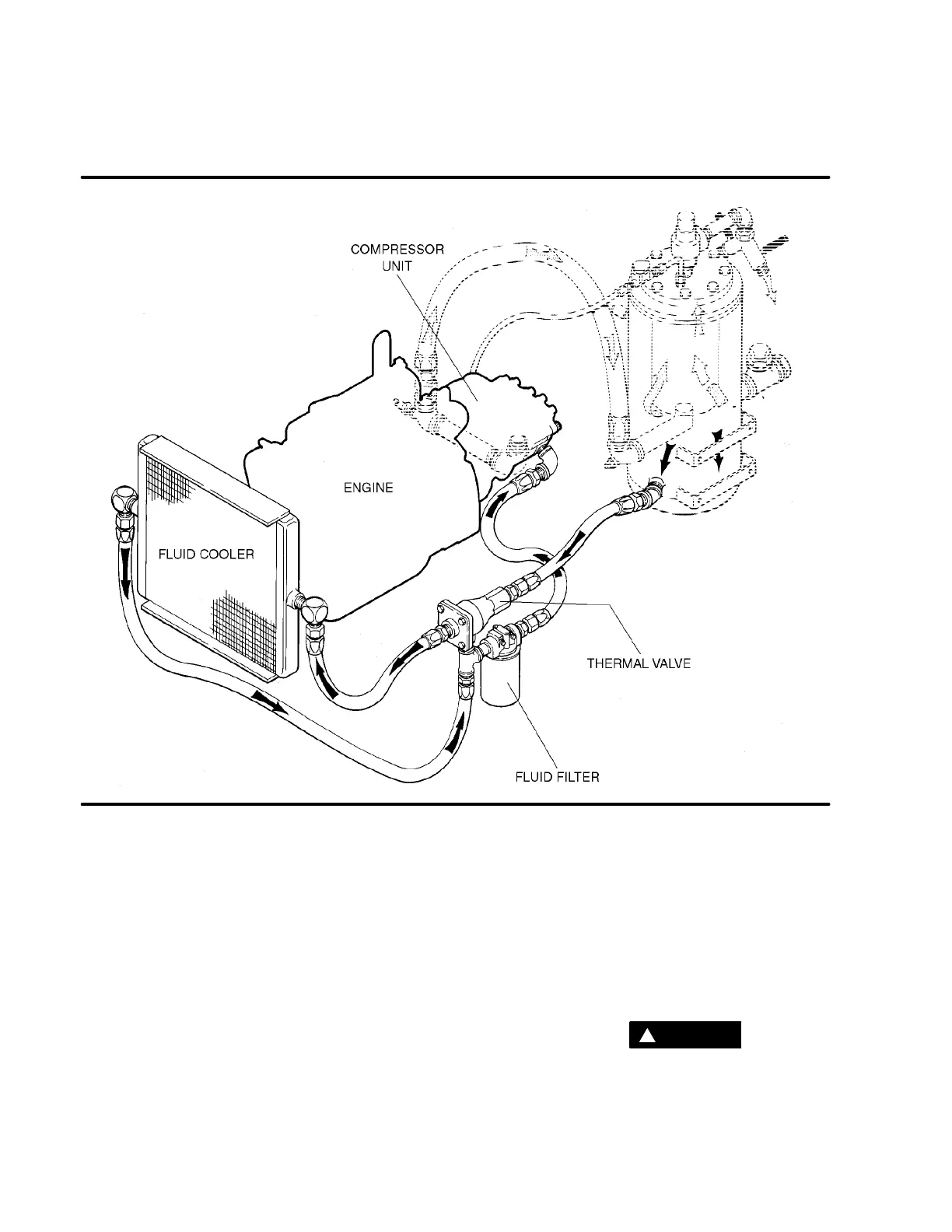

Figure 2 ---2 Compressor Cooling and Lubrication System

droplets of fluid separate a nd fall to the bottom of the

sump. The fractional percentage of fluid remaining

in the compressed air collects on the surface of the

final separator element as the compressed air flows

through the separator. As more and more fluid col-

lects on the element surface, the fluid descends to

the bottom of the separator. A return line (or scav-

enge tube) leads from the bottom of t he separator

element to the inlet region of the compressor unit.

Fluid collecting on the bottom of t he separator ele-

ment is returned to the compressor by the pressure

difference between the area surrounding t he sepa-

rator element and the compressor inlet. An orifice

(protected by a strainer) is included in this return line

to assure proper flow.

The sump is ASME code rated a t 175 psig (12.1 bar)

working pressure. A minimum pressure/check

valve, located downstream from the separator, as -

sures a minimum receiver pressure of 55 psig (3.8

bar) during all conditions. This pressure is neces -

sary for proper air/fluid separation and proper fluid

circulation.

A pressure relief valve (located on the wet side of the

separator) is set to open if the sump pressure ex-

ceeds 140 psig (9.7 bar) or 175 PSIG (12.1 bar) for

“H” machines. A temperature switch will s hut down

the compressor if the discharge temperature

reaches the specified limit given in Section 3, Speci-

fications.

Fluid is added to the sump via a capped fluid filler.

WARNING!

DO NOT remove caps, plugs, and/or other compo-

nents when compr essor is running or pressurized.

Stop compressor and relieve all internal pressure be-

fore doing so.

Loading...

Loading...