Section 5

MAINTENANCE

24

2. With the service valve closed, set the engine low

speed (idle) to its specified setting with the idle

stop screw on the engine injector pump.

NOTE

Operation at speeds below the minimum idle

speeds shown in Section 3 under Specifications

will damage the compressor. Extended operation

below those speeds will induce coupling and/or

compressor failures.

3. Adjust the pressure regulator so t hat t he com-

pressor maintains 117 psig (8.1 bar).

4. Gradually open the service valve to atmosphere

until the engine comes up in speed and sump

pressure is held at 100 psig (6.9 bar). At this

point, set the engine high speed to its specified

setting by adj usting the high idle threaded rod lo-

cated on the engine speed control. To raise or

lower the speed, lengthen or s horten the rod re-

spectively.

5. Open the service valve to 100 psig (6.9 bar) (rated

full load pressure) and recheck top engine

speed and control response. Close the s ervice

valve and allow the compressor to cycle and re-

check low engine speed (idle).

The following explanation applies to “H” compres-

sor with dual pressure controls.

1. Start the compressor and allow the engine to

warm---up to normal operating temperature with

the service valve closed and the pressure selec-

tor switch set to the “low” position.

2. Follow the procedure for setting the controls at

100 psig (6.9 bar) rated full load pressure as de-

scribed in Steps 2 through 5 a bove.

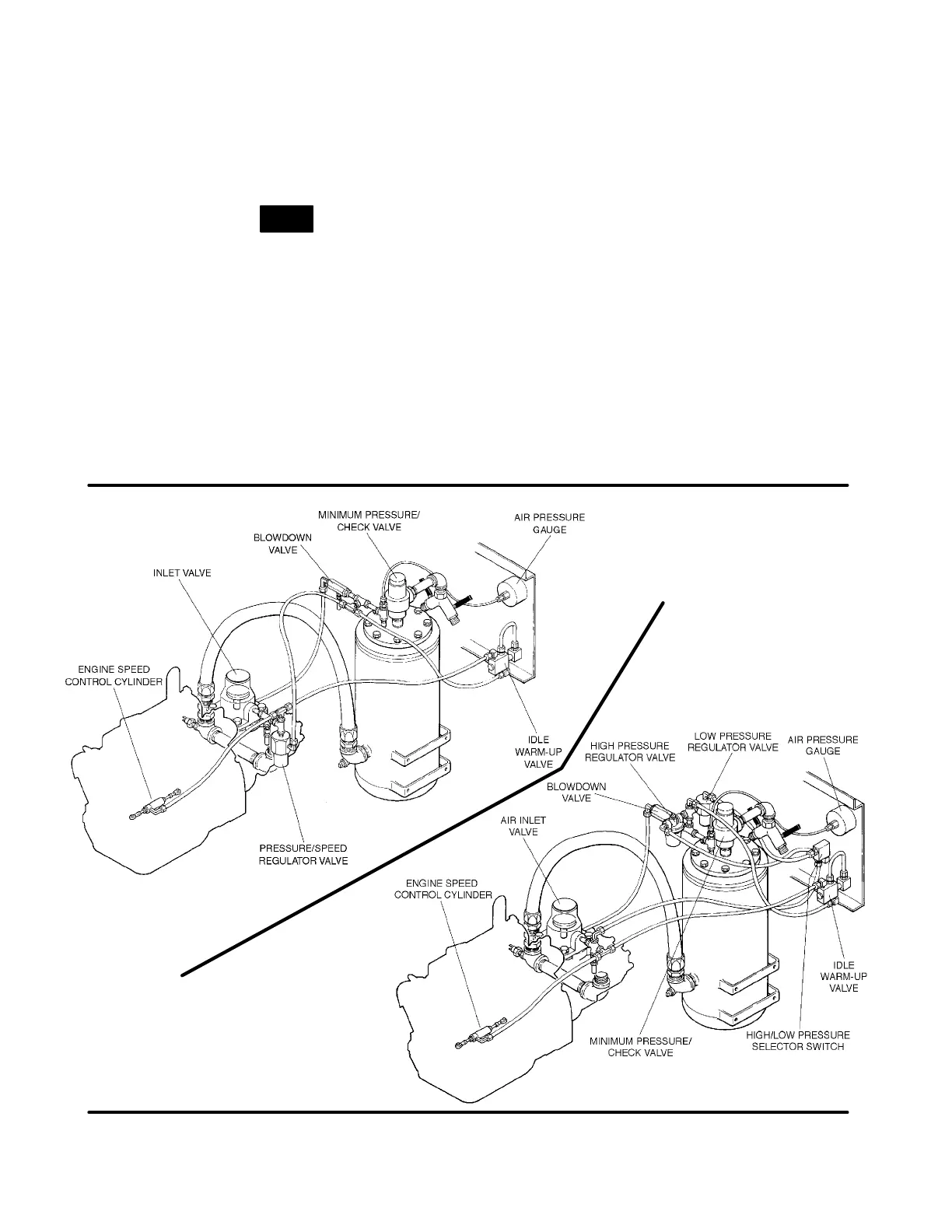

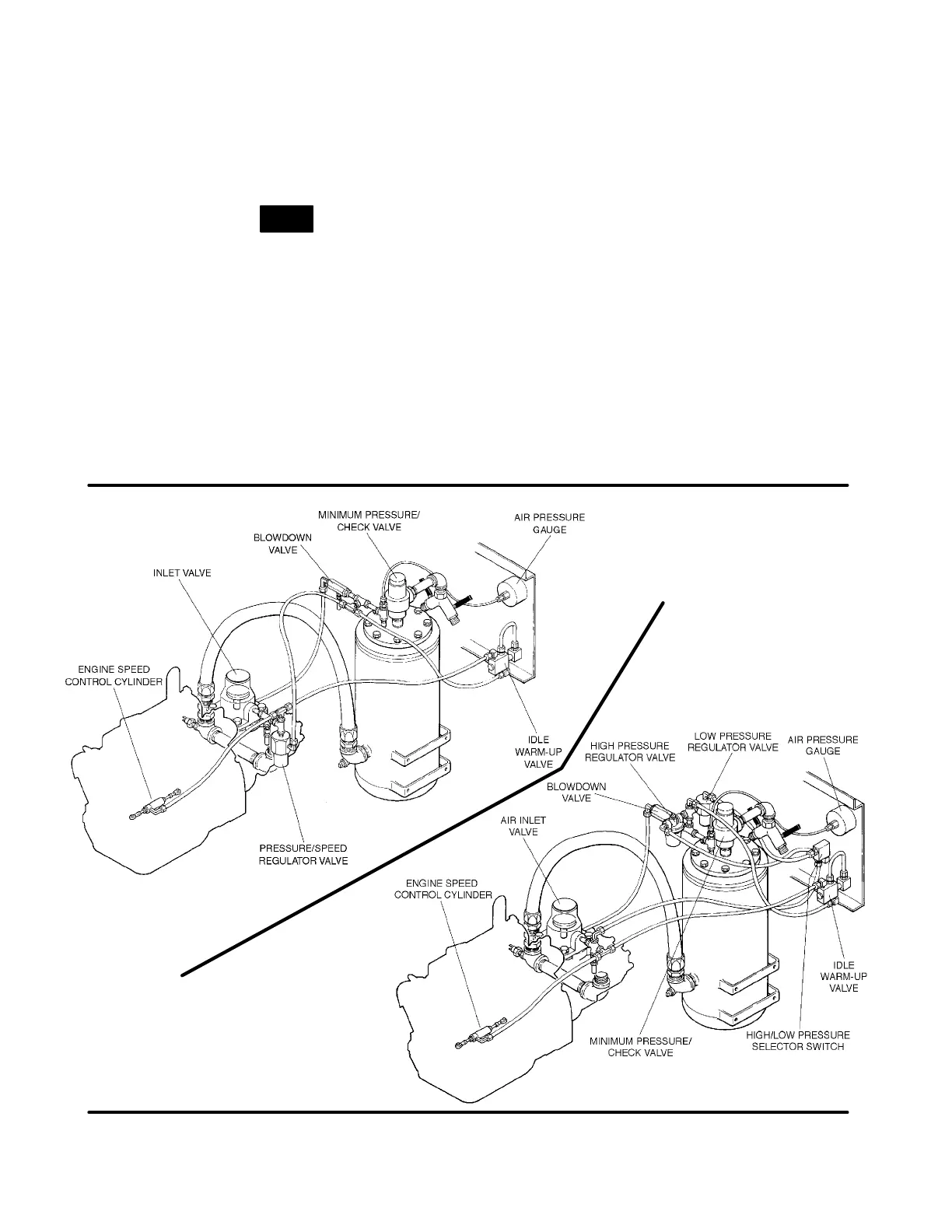

Figure 5 ---4 Control System Adjustment

175/185

185H

Loading...

Loading...