Section 2

DESCRIPTION

11

2.6 CAPACITY CONTROL SYSTEM, FUNCTIONAL

DESCRIPTION

Refer to Figure 2---3 and 2---4. The purpose of the

control system is to regulate the amount of air intake

in accordance with the amount of compressed air

being used. The control system consists of a

pressure regulating valve(s), air inlet valve, sys-

tem blowdown valve, and hoses connecting the

various components to the compressor and en-

gine governor. The functional descriptions of the

control s ystem are given in four distinct phases of

operation. It applies to any control system with the

exception of those with stated pressures which are

dependent on pressure requirements. The pres-

sures stated will be in accordance with a compres -

sor having an operating pressure range of 100 to

110 psig (6.9 to 7.6bar).

START -- 0 TO 40 PSIG (0 to 2.8 BAR)

COLD START

When the compressor is started, the sump pressure

will quickly rise from 0 to 40 psig (0 to 2.8 bar). Dur-

ing this period the pressure regulator valve is inac-

tive. At this pressure range the idle warm---up valve

maintains a closed inlet valve for engine idle opera-

tion. After sufficient machine warm---up is achieved,

push the idle warm---up valve button on the instru-

ment panel. The inlet valve is fully open due to inlet

air pressure, and the compressor operates at full ca-

pacity operation. As the compressor operates at full

capacity, the engine runs at full speed.

NORMAL OPERATION -- 55 TO 100 PSIG (3.8 TO

6.9 B AR) OR 55 TO 150 PSIG (3.8 TO 10.3 BAR)

FOR “H” MACHINES

When the sump pressure rises a bove 55 psig (3.8

bar), the minimum pressure valve opens and deliv-

ers compressed air to the service line. At t his time,

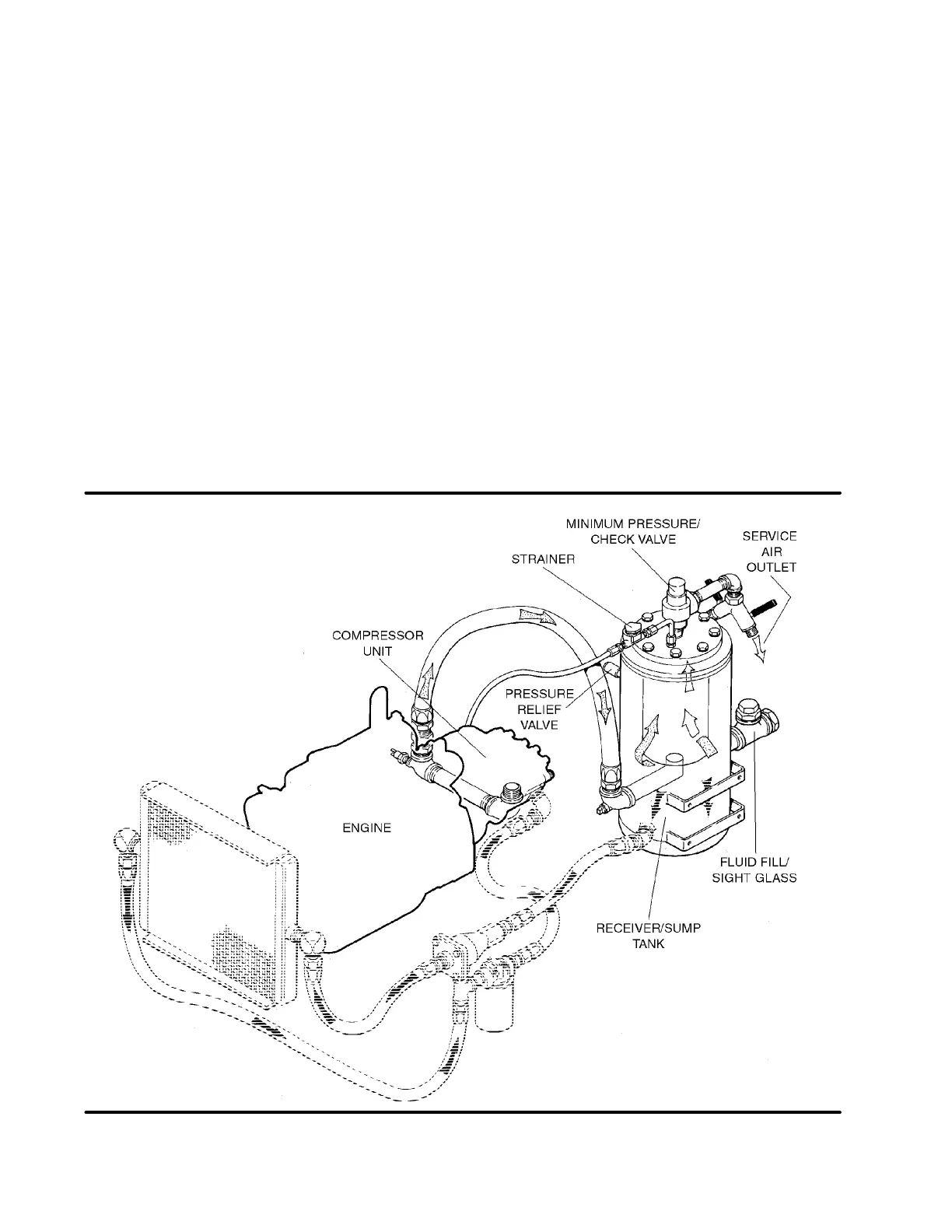

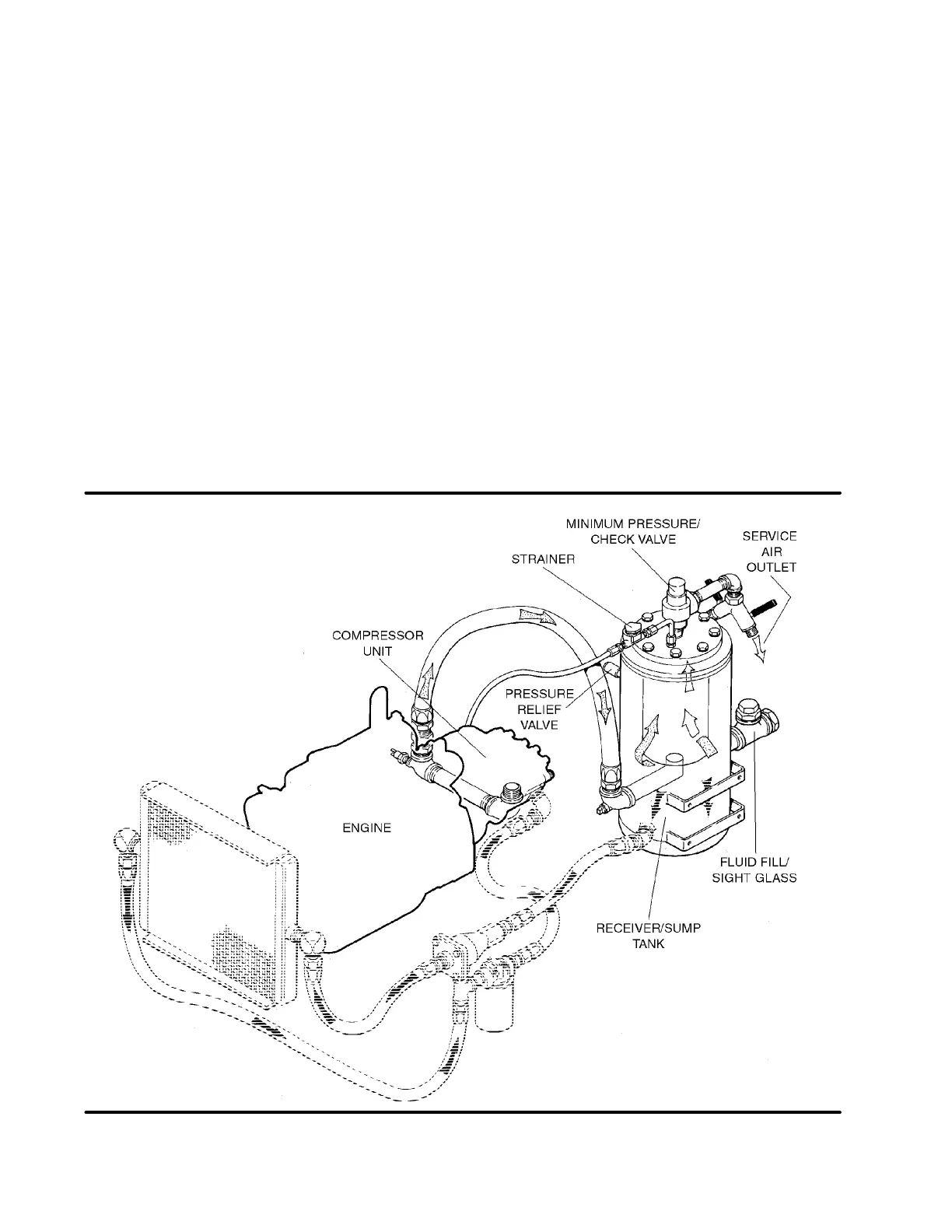

Figure 2 ---3 Compressor Discharge System

Loading...

Loading...