26

5) Adjusting the Height of the Feed Plate.

Unfasten the cylinder knuckle joint nut ③ attached on the left and right cylinders ② on the feed bracket ①. And when

you raise the cylinder knuckle ⑤ to direction A by rotating the cylinder shaft ④, the height(T) of the feed plate ⑥ is set

up highly, and when you lower the cylinder knuckle ⑤ to direction B by rotating the cylinder shaft ④, the height(T) of

the feed plate ⑥ is set up lowly. Be sure to fix the cylinder knuckle joint nut tightly after adjusting the height of the feed

plate ⑥.

[ Fig. 38 ]

①

⑥

③

②

S

⑤

④

A

B

[ Fig. 39 ]

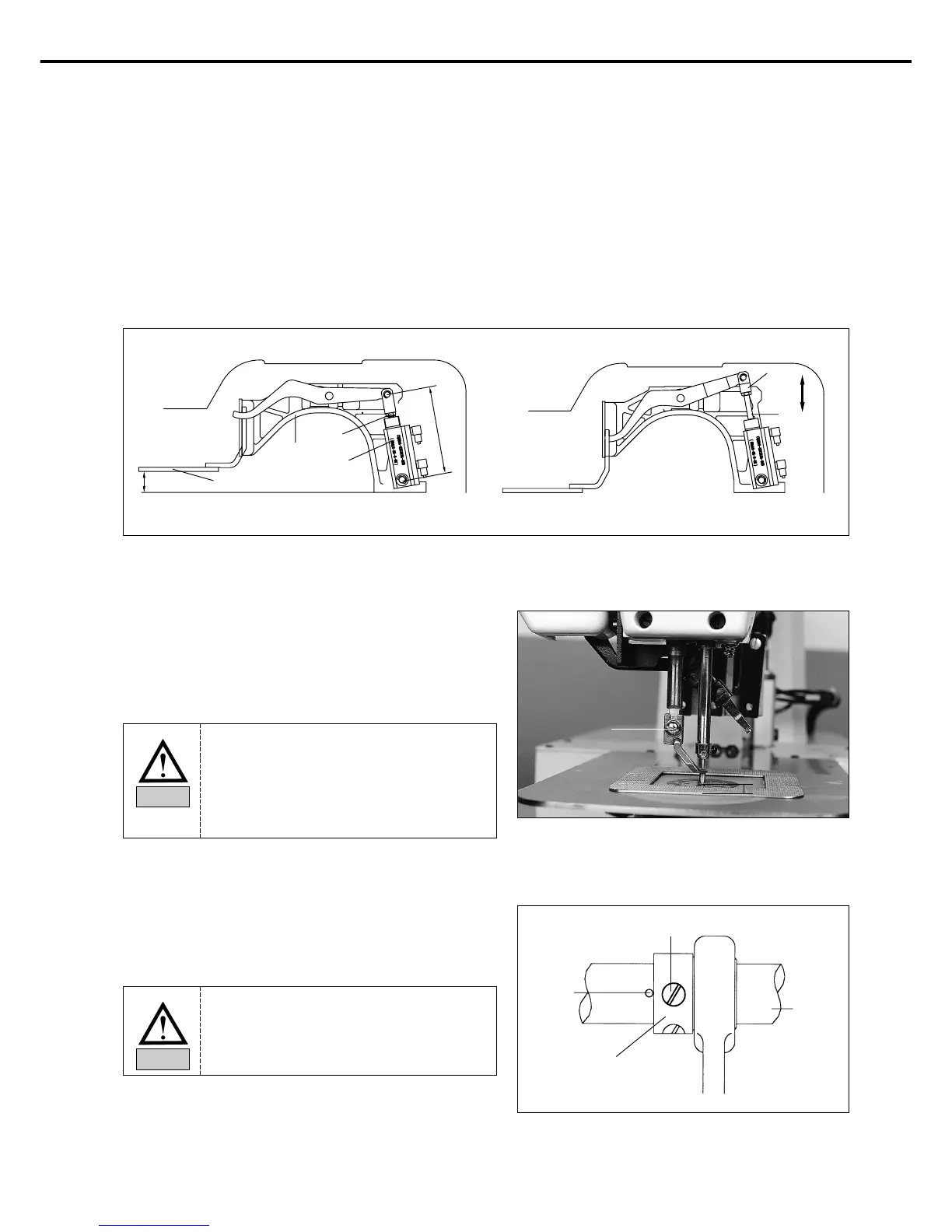

A Unfasten the presser foot joint screw ① at the lowest

position of the needle bar.

B. Adjust the height of the presser foot to correct the

distance between the presser foot bottom surface and

the sewing material to be 0.5mm (the thickness of using

thread) and then fasten the joint screw.

6) Adjusting the Height of the Presser Foot Devices

[ Fig. 40 ]

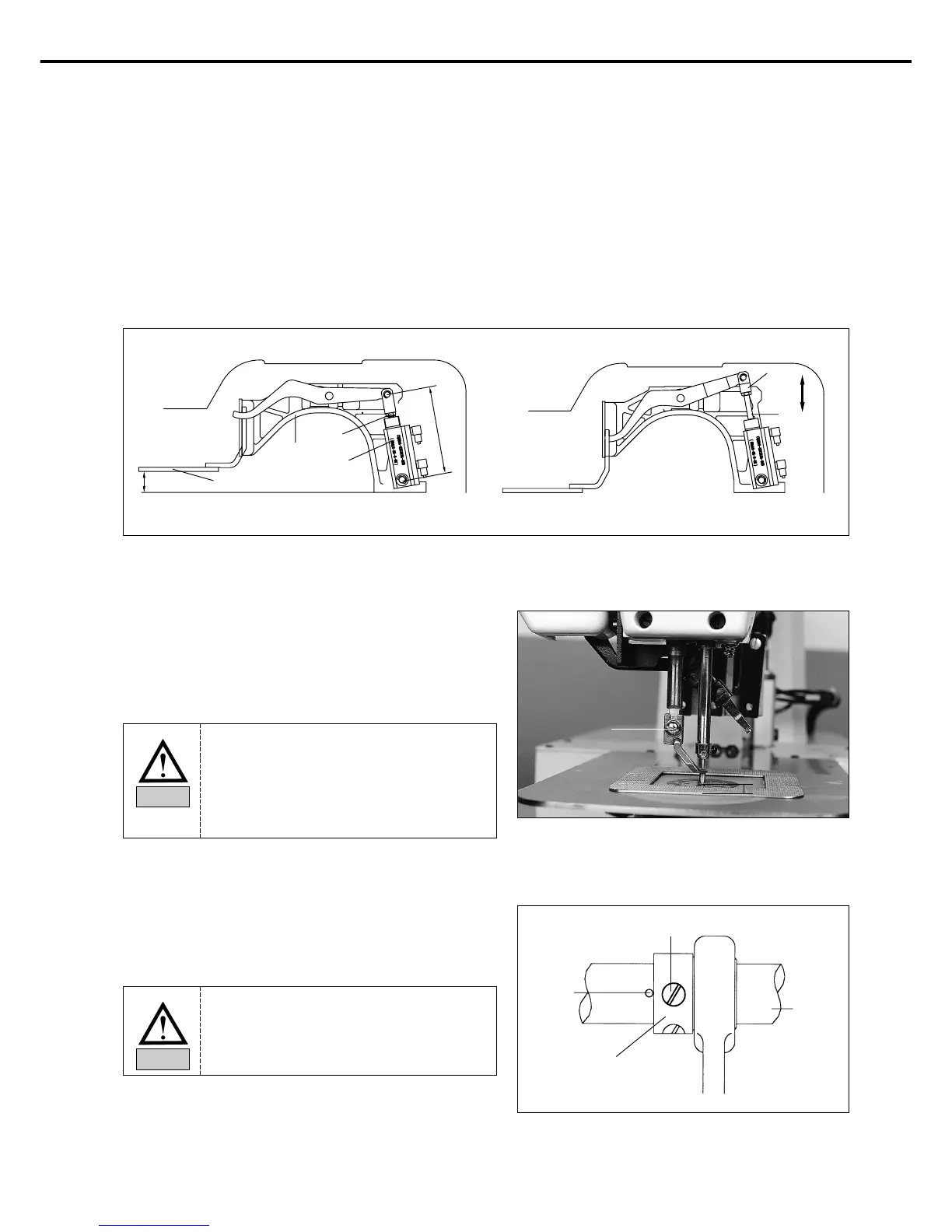

A. Have the end of the presser foot drive cam accord with

the carving point center of the upper shaft, and the line of

the cam accord with the carving point.

Tighten screw ①.

7) Adjusting the Presser Foot Devices

①

→

→

0.5mm

①

Carving

Point

Presser Foot Drving Cam

Upper

Shaft

T

Make sure to check the position of the wiper

after adjusting the height of the presser foot.

·A flipping away shall be caused by a wide

interval.

·A malfunction of the thread adjusting shall be

caused by a narrow interval

Caution

lf the presser foot drive cam is not in

the rigth position, the presser foot

may move vertically in time and run

into needle bar.

Caution

Loading...

Loading...