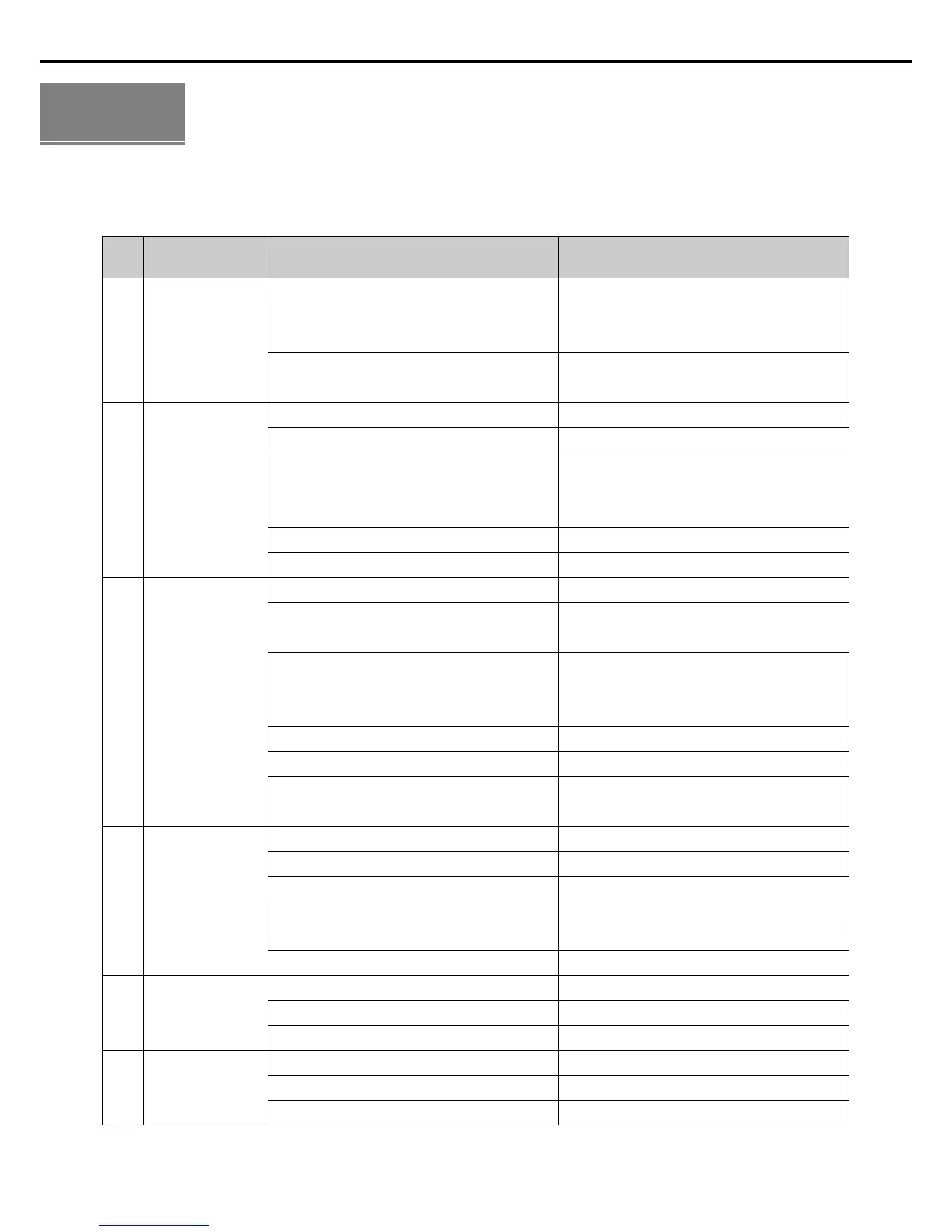

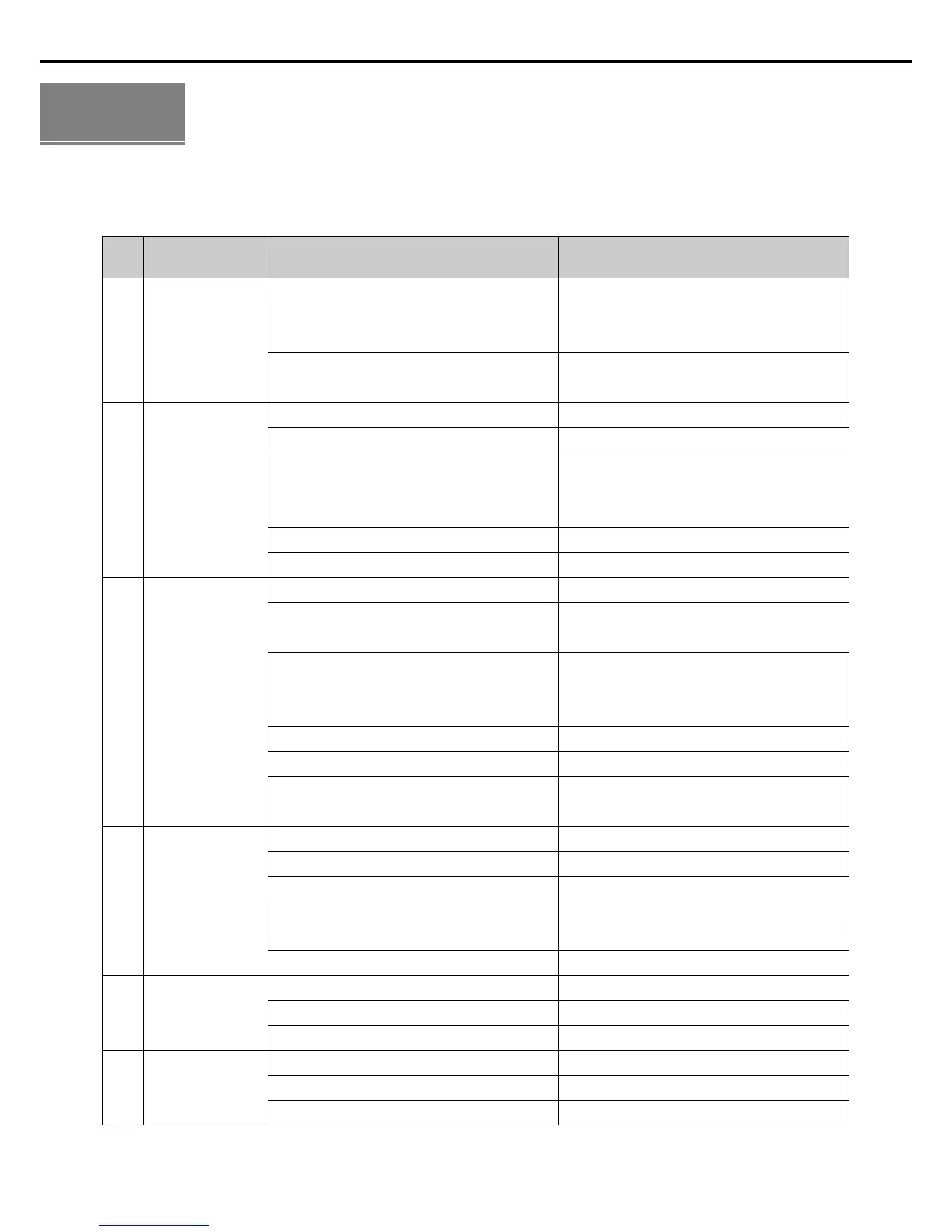

36

77

CAUSE OF BREAKDOWN AND TROUBLESHOOTING

Adjust the belt tension or exchange it.

1

No.

Condition of

Breakdown

TroubleshootingCause of Breakdown

Error on operation

or drive of machine

Loosing of belt tension and damage on belt.

Fuse shortage for main power or circuit

Deviation from Y and Y limit of feed bracket

2

Bad position of

stopping position

Slackness of main drive belt

Due to improper synchro position

Adjsut the belt tension

Adjsut setting position of synchro

3

4

5

6

7

Needle bent

Thread is cut

Stitich skipping

Errorin thread

tightening

Error in trimming

Damage on needle.(Bending of needle, cracks on

needle hole or groove, and, abrasion or

transformation of needle tip)

Exchange the needle

Wrong installation of needle

Contact of needle with shuttle

Install the needle properly

Adjust the distance properly between a needle and shuttle

Wrong insertion of therad

Wrong installation of needle (Height of needle or

direction of needle tip)

Damage on needle(Bending of needle, cracks on

needle hole of groove, and abrasion or

transformation of needle tip)

Exchange the needle.

Excessive tension of upper thread and under thread

Excessive tension and stroke of take-up lever spring

Adjust the tension

Adjust the tension and stroke of take-up lever spring

Crack on the controlling hole of shuttle surface

spring

Reinstall the needle

Insert the thread properly

Exchange the shuttle surface spring

Use of bending needle

Use of improper sized needle compared with using thread

Wrong installation of needle

Improper timing for needle and shuttle

Improper gap between groove and shuttle point

Excessive tension of take-up lever spring and stroke

Weak tension of upper thread

Weak tension of lower thread

Improper timing for needle and shuttle

Laxity of exchanging tension between movable mes and fixed mes

Abrasion and crack on blade of movable mes and fixed mes

Wrong position of trimmimg cam.

Readjust the tension of fixed mes.

Exchange the movable mes and fixed mes

Readjust the position of trimming cam

Readjust the tension of upper thread.

Readjust the tenson of lower thread.

Readjust the timing for needle and shuttle

Exchange the needle

Exchange the needle

Reinstall the needle.

Readjust the timing for needle and shuttle

Readjust the timing for needle and shuttle

Adjust the tension of take-up lever spring and stroke

1) Machine Part

Check the fuse shortage of main shaft drive motor in

a controller box or exchange it

Move the feed bracket to normal place

(inside limit switch)

Loading...

Loading...