19-38 C D/B O’ M

short, at stock only. To adjust, remove the four

tension adjusting screws, keeping track of screw

penetration into retaining nut. Slide rollers in toward

drum using retaining nut closest to drum. Reinstall

four adjusting screws with the same tension or

penetration into retaining nut. See page 26.

Flat Surfaced Stock: Loosen the four socket head

screws holding the tension roller brackets. Place

stock under brush. Lower brush to proper bristle

penetration. Raise brush two-to-three revolutions.

Tighten the four socket head screws. Remove stock,

lower brush head to previous setting when adjusting

and brush material.

Bristle Contact: Proper bristle penetration is critical

for the best nish and longest brush life. Flatter brushes

should be set to penetrate between 1/8 to ¼” into

the deepest part of the pro le being sanded. Nylon

brushes should be set to penetrate approximately

1/16” into the deepest part of the pro le being

sanded. Wire brushes should be set to penetrate 1/32

to 1/16” into the material being brushed.

S B S F R

Selecting the proper feed rate is essential to proper

Brushing and sanding. Feed rate controls the duration

or “dwell time” of brushing on the contact area. A

slower feed rate allows more brushing to occur. In

some instances, a slow feed rate and slow brush speed

may produce the same result as a fast feed rate and

fast brush speed. e variable feed rate control of

the conveyor belt adjusts the load on the machine;

it can be in nitely adjusted for maximum operating

performance. A faster feed rate allows faster brushing

but fewer revolutions of the brush per inch of sanding.

A slower feed rate provides more revolutions of the

brush per inch of sanding (Fig. 10).

e best feed rate will depend on a number of factors,

including type of stock, brush, depth of cut used,

and whether the stock is fed directly in line with the

conveyor bed or at an angle. When testing feed rates,

begin with a mid range (50%) setting and adjust faster

or slower depending on conditions and performance.

D S F R

Selecting the proper feed rate is essential to proper

nish sanding. For nish sanding the best nish is

usually achieved with a slow to moderate feed rate,

after the proper depth of cut has been determined.

is allows for the most revolutions of the drum per

inch of sanding. When abrasive planning, faster feed

rates can be used as long as the machine is not over

stressed. Please note, angling stock as it is sanded

will allow the most e ective stock removal and

least loading of the abrasives. Feeding stock straight

through yields the widest sanding capacity and least

noticeable scratch pattern.

Please note; when drum sanding with RPM adjusted

to fastest speed, INTELLISAND will automatically

adjust the conveyor feed rate if an excess load is

detected. is prevents excessive gouging, reduces

the risk of burning and it protects the machine from

overload or stalling. e red light by the adjustment

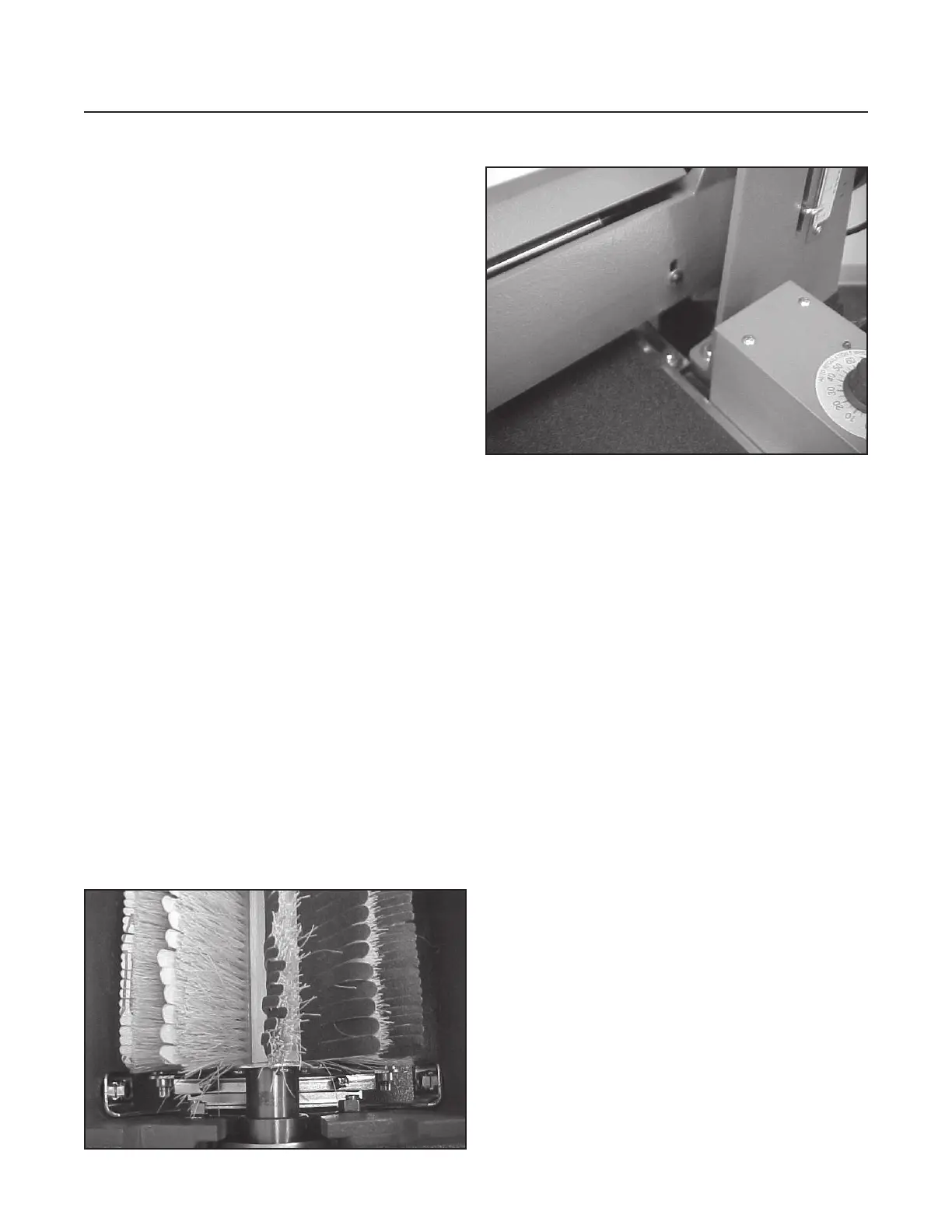

Fig. 11 Tension rollers and adjustment bracket

Fig. 11A Tension roller height and depth gauge adjustment

Loading...

Loading...