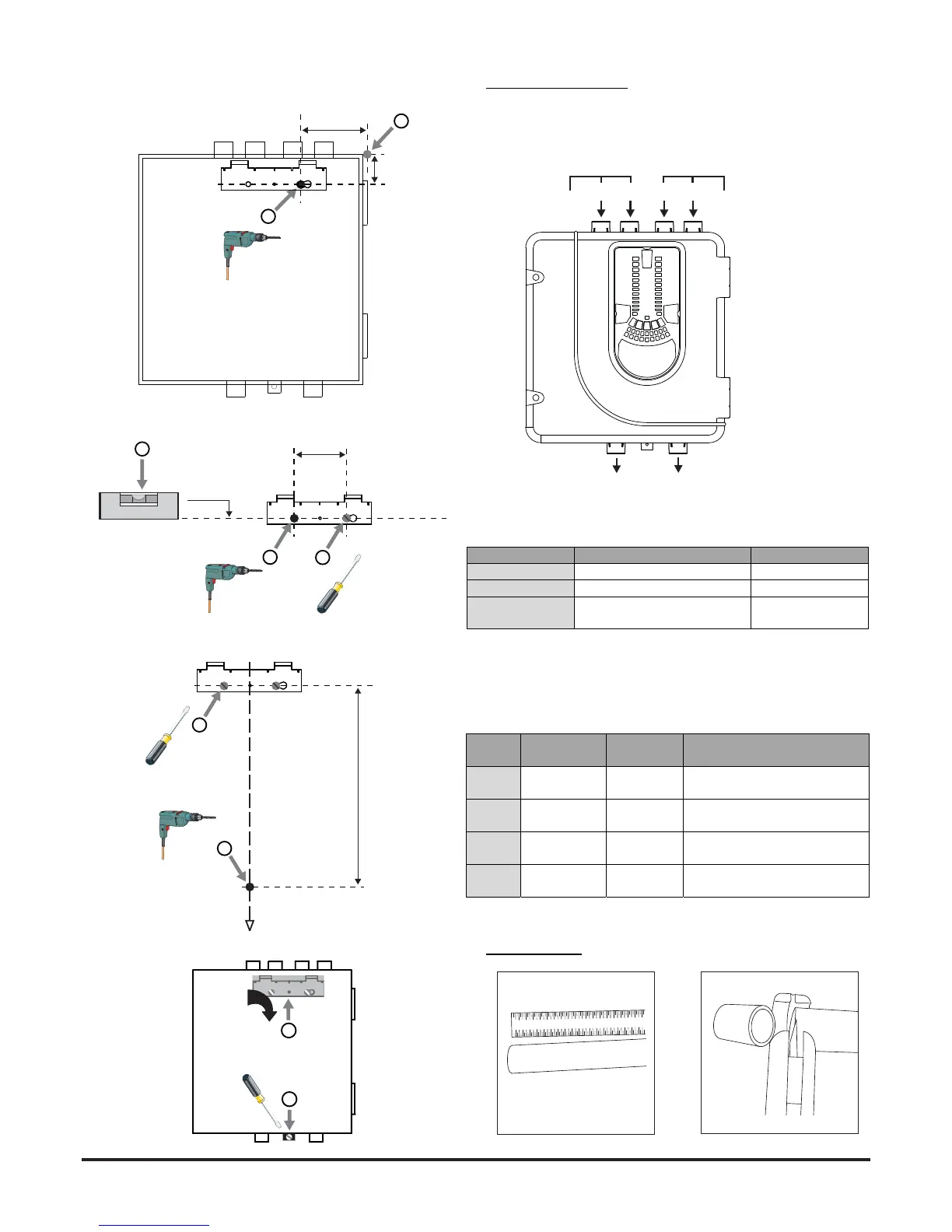

Figure 7: Sequence (1 to 9) to Mount the Detector on the Bracket

Pipe Installation

1 2 3 4 5 6 7 8 9 10 1112 13 14 1516

17 18

99 mm

41

1

2

mm

90 mm

4

3

0.00

o

5

329 mm

6

7

7a

7b

7c

7d

8

9

21

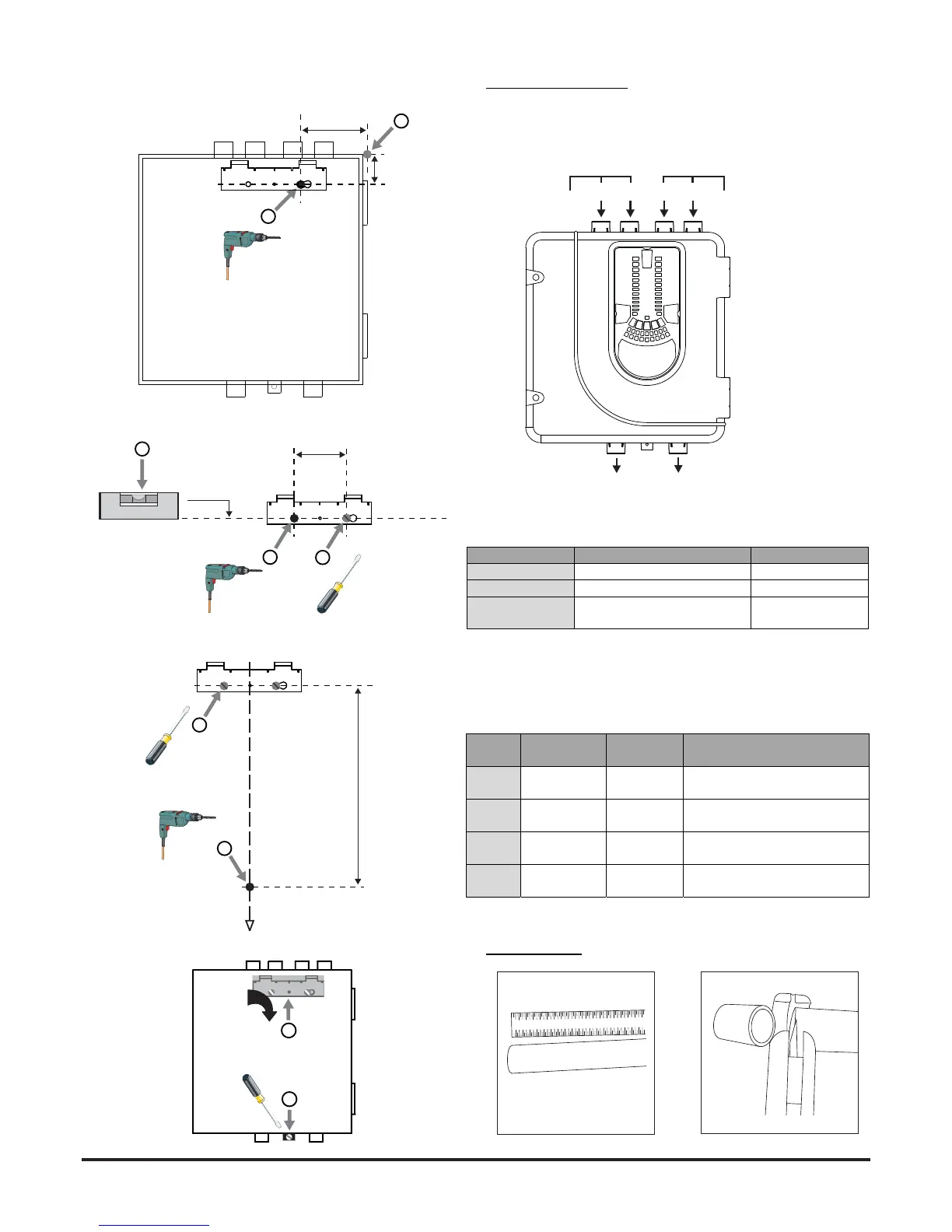

Pipe Hole Conguration

Figure 8 below shows the pipe holes available on the unit. Each unit

has 2 pipe holes per channel connected together like a T-Piece. If

using a 1 channel unit, holes 3 and 4 do not function. Use Table 1 to

locate the holes required for the installation:

Figure 8: Pipe Holes

Table 1: Pipe Holes Used for Each FAAST LT-200 Model

Note 1: Pipe holes not used should be kept sealed.

Note 2: Do NOT glue pipes into the pipe holes.

Table 1a: Maximum Number of Pipe Holes Allowed Per Channel

All gures quoted using highest (level 1) sensitivity

1

2

3

4

5

6

CHANNEL 1

CHANNEL 2 (ONLY FUNCTION

ON 2 CHANNEL UNITS)

CHANNEL 1 (NOT

USED FOR COMMON

CHAMBER UNIT)

CHANNEL 2 (ONLY

FUNCTIONS ON 2

CHANNEL AND COMMON

CHAMBER UNITS)

FAASTLTMODEL INLETPIPEHOLE OUTLETPIPEHOLE

FL0111E‐HS 1and/or2 5

FL0112E‐HS 1and/or2 6

FL0122E‐HS Channel1‐1and/or2

Channel2–3and/or4

5

6

C 100 18 6x2mm+6x2.5mm+6x3mm

(+3.5mmnonsensingendhole)

C 160(2x80)

UsingT‐Piece

18(9x2) 2x[3x2.5mm+6x3mm]

(+3mmnonsensingendhole)

B 80 6 6x4mm

(inc4mmsensingendhole)

A 80 3 1x5mm+1x6mm

Loading...

Loading...