Rollshutter Installation Instructions, 12

©Copyright TALIUS

diagrams for such systems are available upon request or can be found on mytalius.com. Under no circumstances should

the installer deviate from the wiring diagrams and change items or hook-up patterns. Never use any electrical

components that were not supplied by the manufacturer. Never connect wires of two or more tubular motors

together, unless specifically instructed on certain motor types. Tubular motors are highly specialized units with custom

designed switching mechanisms. Even simple looking items are specifically designed for these units. Any changes will

almost certainly result in catastrophic damage! Over the years we have seen motorized units damaged by

electricians who believed they comprehended the principles behind tubular motors. It is very tempting to see a simple

design in the motor configuration, but this is wrong. The description supplied with this job does not contain enough

information to explain the intricacies of a tubular motor and it cannot be deduced from the components! Finally, it is

essential that each Rollshutter dealer own a set of motor tester cables which can be obtained from the factory.

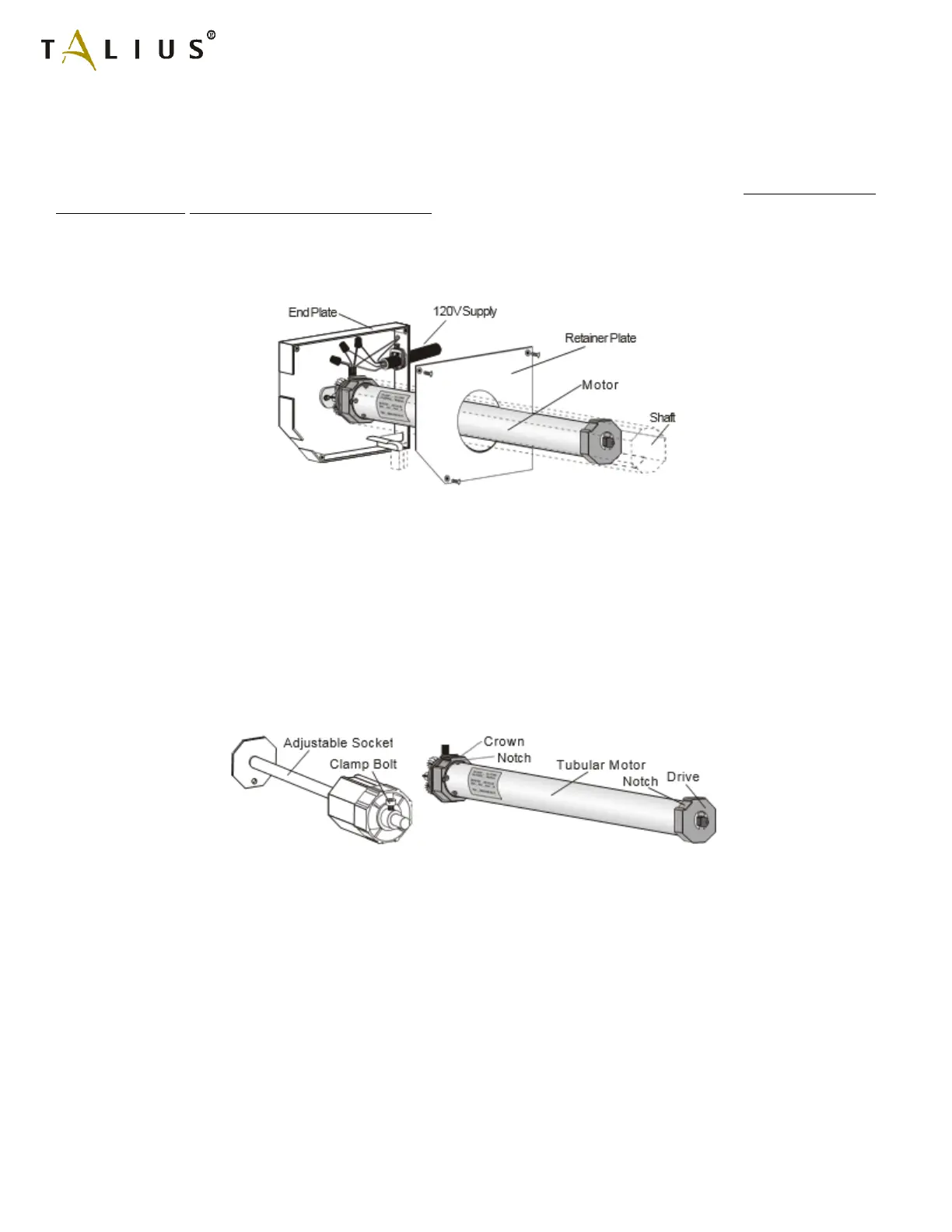

If the motor operator is equipped with a manual override begin by looking up Section 6.1a for the installation of the

manual override crank rod. If the motor is located in a panel box and fitted with a metal retainer plate, slide the retainer

plate away to clear access to the motor. Hook up the tester cables by matching the colour coded clamps to the

coloured wire ends. If a tester cable is not available have the electrician hook up the motor to the switching mechanism

as outlined in the wiring diagram. From this point on in the installation it is imperative that the motor is located fully

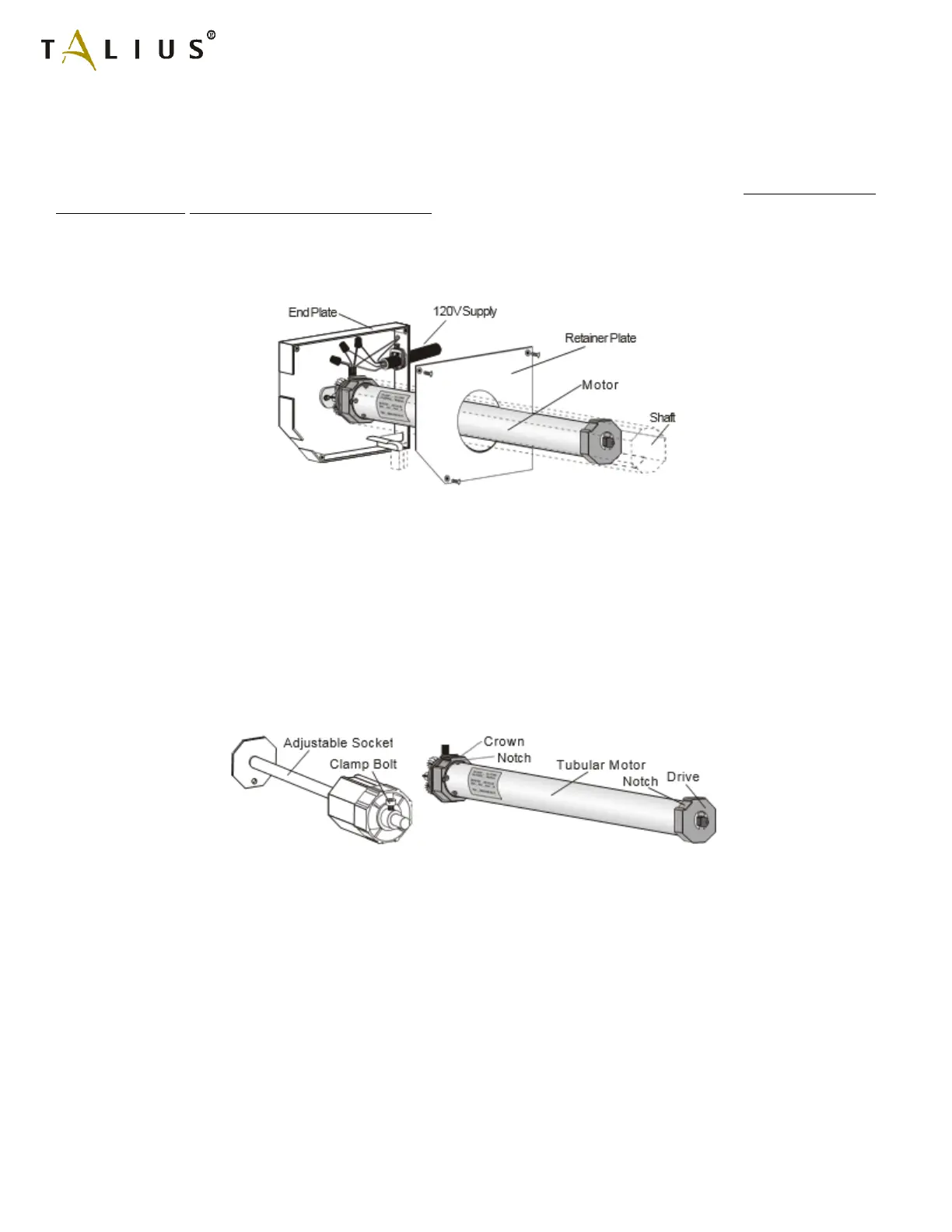

inside the shaft. Especially on rolling doors, ensure that the crown is securely located between the notch in the motor's

drum and the shaft. The shaft must be secured so that it cannot slide sideways, which requires that the clamp bolt on

the adjustable socket, if so outfitted, is screwed tight while pushing the socket against the end of the shaft. Switch the

tester cable so that the top of the shaft turns in the downward direction towards the panel box. Continue until the

motor comes to a stop by itself. The shaft has now reached what will later be its lower limit. The factory normally

presets the shaft so that it starts out already at or close to the lower limit. Therefore, the motor may not even have

operated at all or only for a very brief moment.

Loading...

Loading...