13

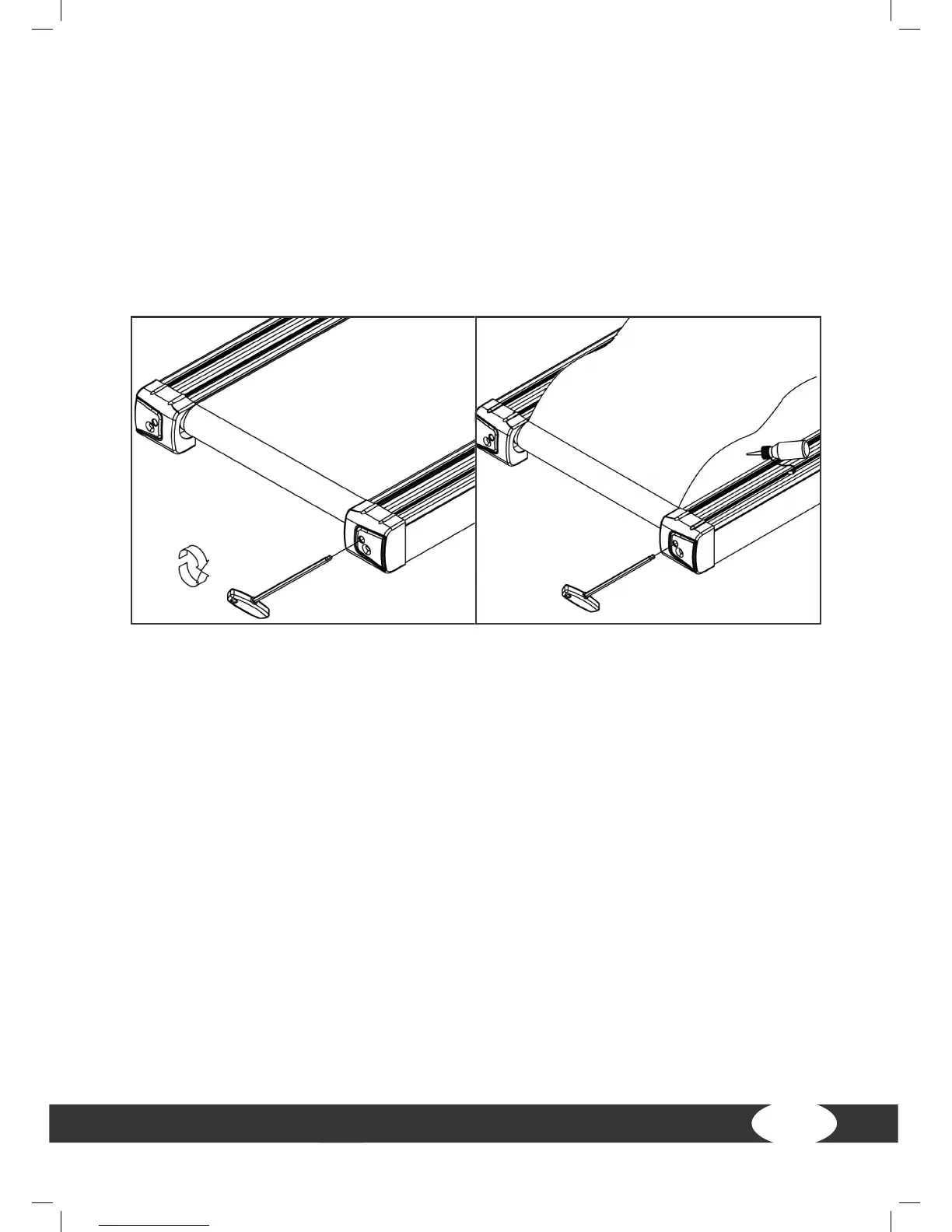

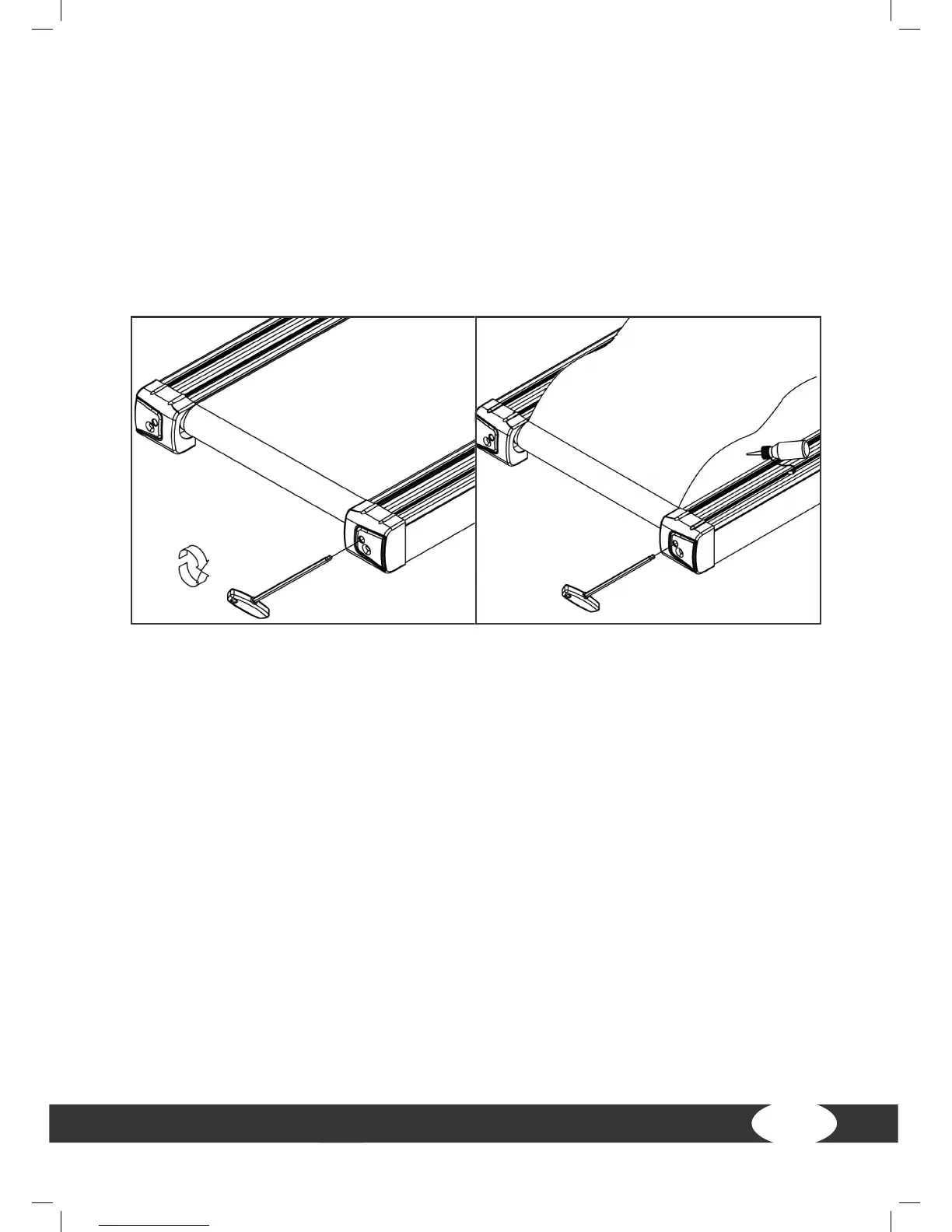

+ If the running belt is oset to the right, turn the right setting screw on the rear end

of the equipment at most 1/4 rotation clockwise and the left setting screw at most

1/4 rotation counterclockwise (g. D).

+ Then watch how the belt runs for approximately 30 seconds, because the change

will not be visible immediately.

+ Repeat the process until the running belt runs straight again. If the running belt

cannot be adjusted, please contact your contract partner.

Tensioning the belt

+ If the running belt slips over the rollers during operation (if this is the case, a

noticeable jerking will be noticed while running), the running belt must be

tightened again. In most cases, the cause for the slipping is a straining of the belt

through usage. This is completely normal.

+ It can be tightened through the same setting screws that were used during

alignment.

+ While tensioning the belt, let the equipment run with a speed of 5km/h.

+ Turn the left and right setting screws directly after each other a max. of 1/4 rotation

clockwise.

+ Then check if the running belt is still slipping. If this is still the case, the described

process needs to be repeated.

Loading...

Loading...