22

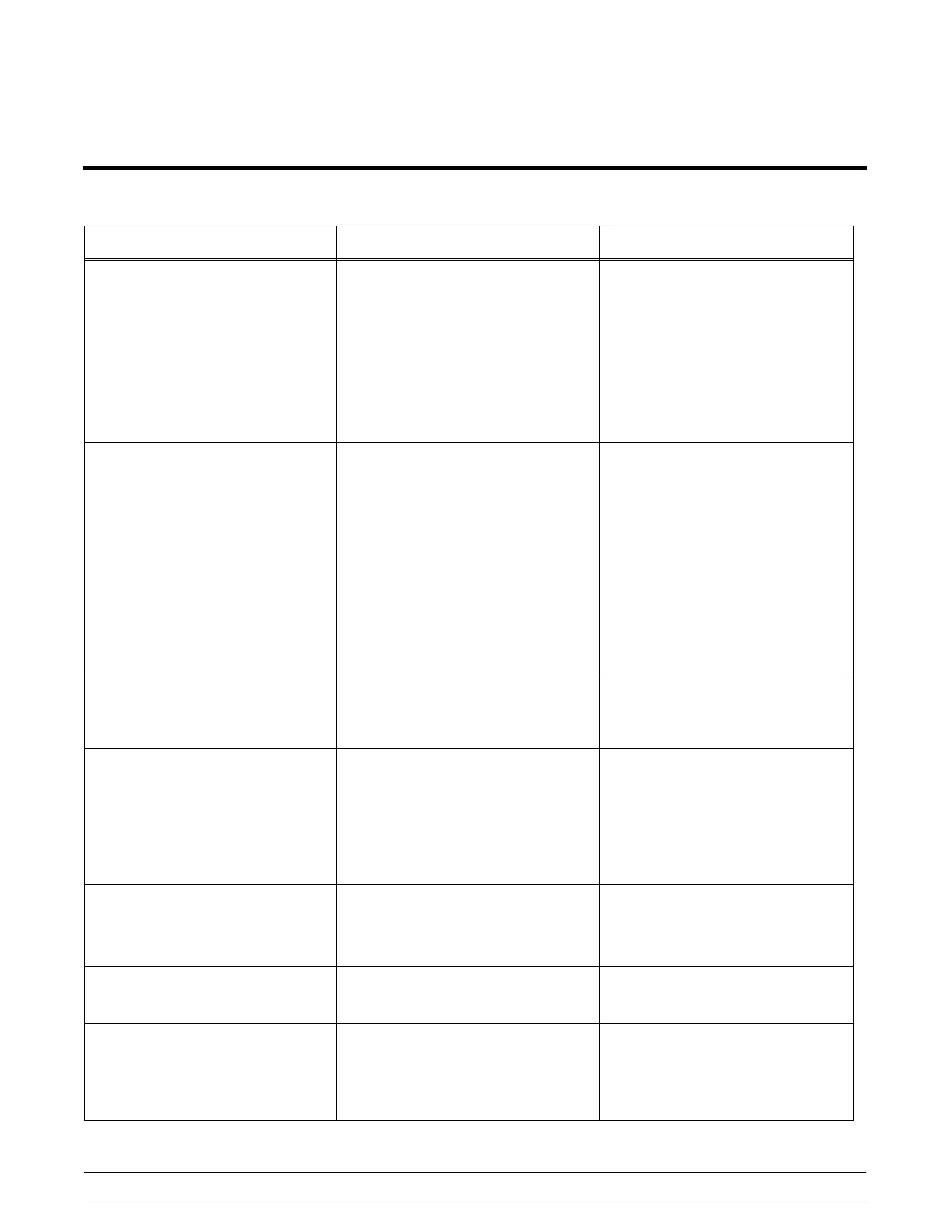

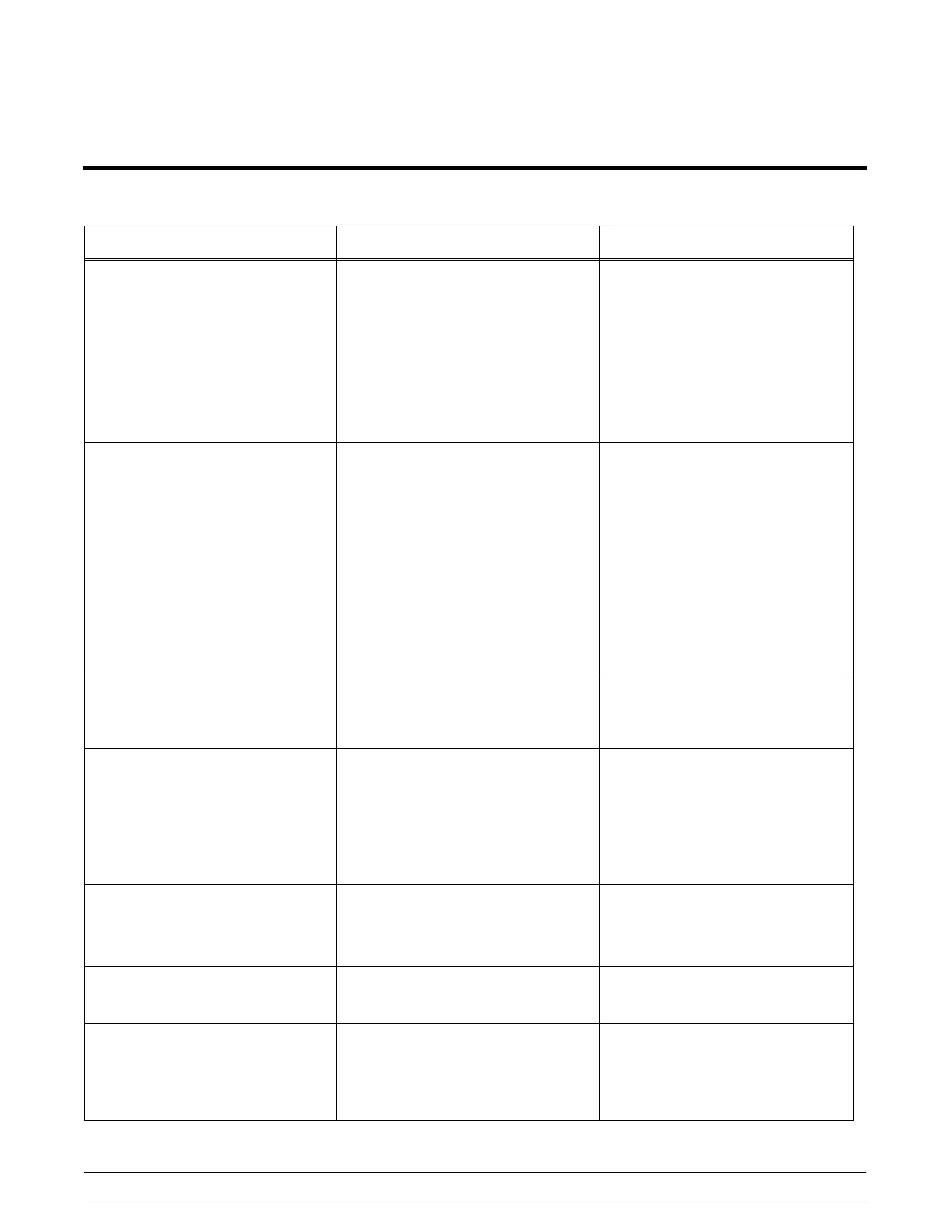

Troubleshooting

Model 430

General Troubleshooting Guide

PROBLEM PROBABLE CAUSE REMEDY

1. No freezer operation with power

switch in the “AUTO” position.

a. Unit unplugged. a. Plug main power cord in the wall

receptacle.

b. Fuse blown or circuit breaker in the

“OFF” position.

b. Replace the fuse or place breaker

in the “ON” position.

c. The beater motor is out on reset. c. Place the control switch in the

“OFF” position and press the reset

button firmly. Place the power

switch in the “WASH” position and

observe the freezer’s performance.

Resume normal operation.

2. With the power switch in the

“AUTO” position, the beater motor

runs, but the compressor does

not operate.

a. Tripped internal overload in the

compressor.

a. Allow the internal overload to cool.

Check for high head pressure,

refrigerant overcharge, stuck

pistons, or tight bearings.

b. Compressor is burned out. b. Replace the compressor.

c. Compressor is improperly wired. c. Check wiring against diagram on

compressor.

d. Low line voltage. d. Check the line voltage at terminal

block. Locate cause of voltage

drop.

e. Single-phasing compressor

contactor.

e. Replace the compressor contactor.

3. Unit short cycles. a. Cycling on high pressure cut-out.

Cut in: 404A: 340 PSI (2,344 kPa.)

Cut out: 404A: 440 PSI (3,034 kPa.)

a. Check the water supply (water-

cooled units only), and make sure

the condenser is clean. Check for

potential refrigerant overcharge.

4. Compressor hums intermittently,

but will not start. Cycling on

overload.

a. Compressor is improperly wired. a. Check wiring against the diagram.

b. Low line voltage. b. Check the main line voltage, and

locate voltage drop.

c. Relay contacts not closing. c. Check by operating manually.

Replace defective relay.

5. Product too stiff. a. Temperature or viscosity control is

set too cold.

a. See the “Thermistor Control” or

PCB A. section in this manual to

reset the control.

b. Inadequate mix in the hopper. b. Fill hopper with mix.

6. Product too soft. a. Temperature or viscosity control is

set too warm.

a. See the “Thermistor Control” or

PCB A. section in this manual to

reset the control.

7. Head pressure too low. a. Shortage of refrigerant. a. Locate and repair leak. Recover

the refrigerant, evacuate, and

charge the system.

b. Water valve stuck open (water

cooled unit).

b. Clear, or replace the valve.

Loading...

Loading...