6-2

OPERATING PROCEDURES

Model 8756

Operating Procedures

6

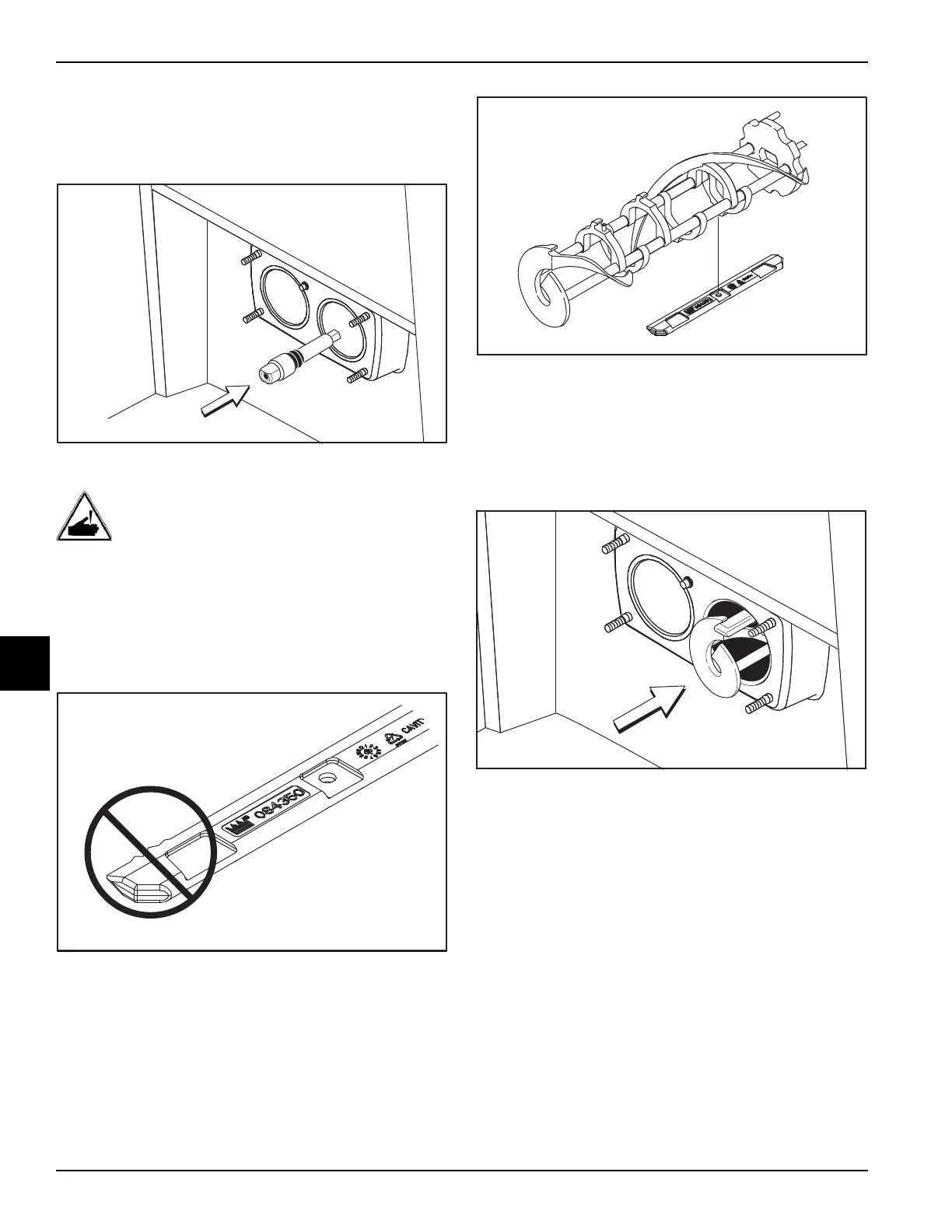

3. Install the driveshaft through the rear shell bearing in

the freezing cylinder and engage the hex end firmly

into the gearbox coupling. Make sure the driveshaft

fits into the drive coupling without binding.

Figure 6-3

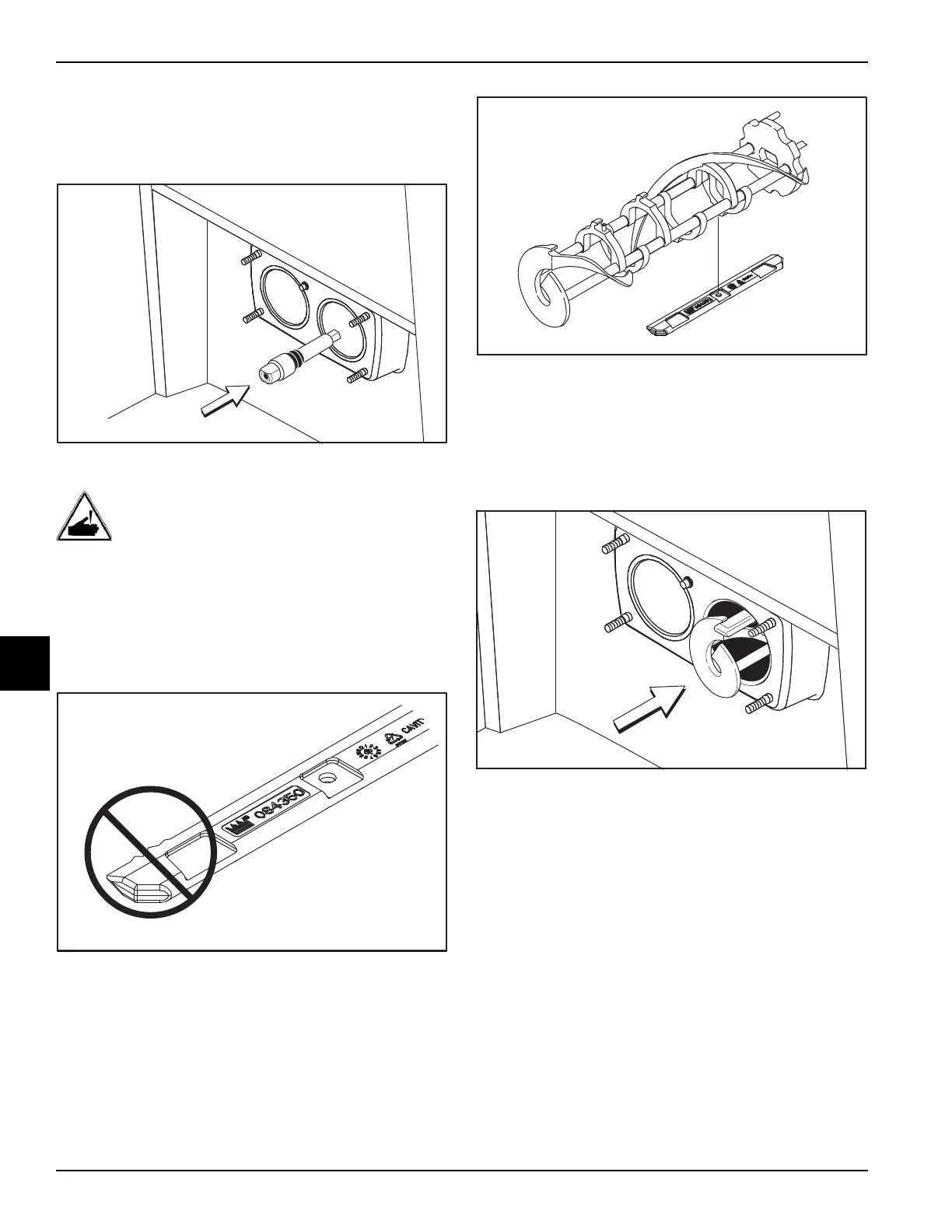

WARNING! Use extreme caution when

handling the beater assembly. The scraper blades are

very sharp and may cause injury.

4. Before installing the beater assembly, check the

scraper blades for nicks or signs of wear. If any nicks

are present, replace the blades.

Figure 6-4

5. If the blades are in good condition, place the rear

scraper blade over the rear holding pin on the beater.

Important! The hole on the scraper blade must fit

securely over the pin to prevent costly damage.

Figure 6-5

Note: Scraper blades should be replaced every

3 months.

6. Holding the rear blade on the beater, slide it halfway

into the freezing cylinder. Install the front scraper

blade over the front holding pin.

Figure 6-6

7. Before installing the beater shoes, check the shoes

for any nicks, cracks, or signs of wear. If defects are

present, replace the beater shoes.

Loading...

Loading...