OPERATING PROCEDURES

6-3

Model 8756

Operating Procedures

6

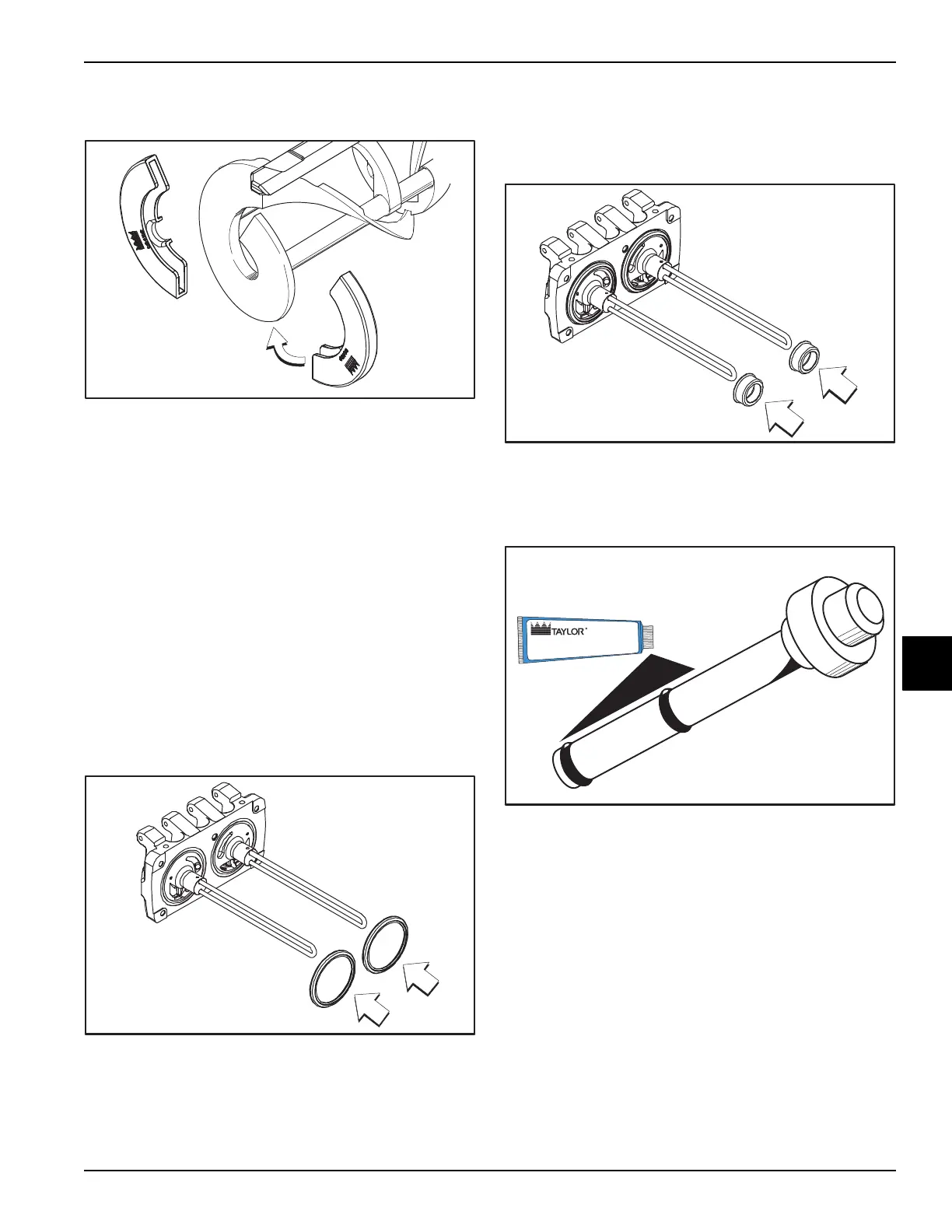

8. Install the beater shoes. Slide the beater assembly

the rest of the way into the freezing cylinder.

Figure 6-7

9. Make sure the beater assembly is in position over the

driveshaft. Turn the beater slightly to make sure it is

properly seated. When in position, the beater will not

protrude beyond the front of the freezing cylinder.

10. Repeat these steps for the other side of the

freezer.

Freezer Door

1. Before assembling the freezer door, check the

following for any nicks, cracks, or signs of wear: door

bearings, door gaskets, draw valves, O-rings, and all

sides of the door assembly, including the inside of the

draw valve bores. Replace any damaged parts.

2. Place the large rubber gaskets in the grooves on the

back side of the freezer door.

Figure 6-8

3. Slide the white plastic front bearings over the baffle

rods. Make sure that the flanged end of the bearing is

resting against the freezer door. Do not lubricate the

gaskets or the front bearings.

Figure 6-9

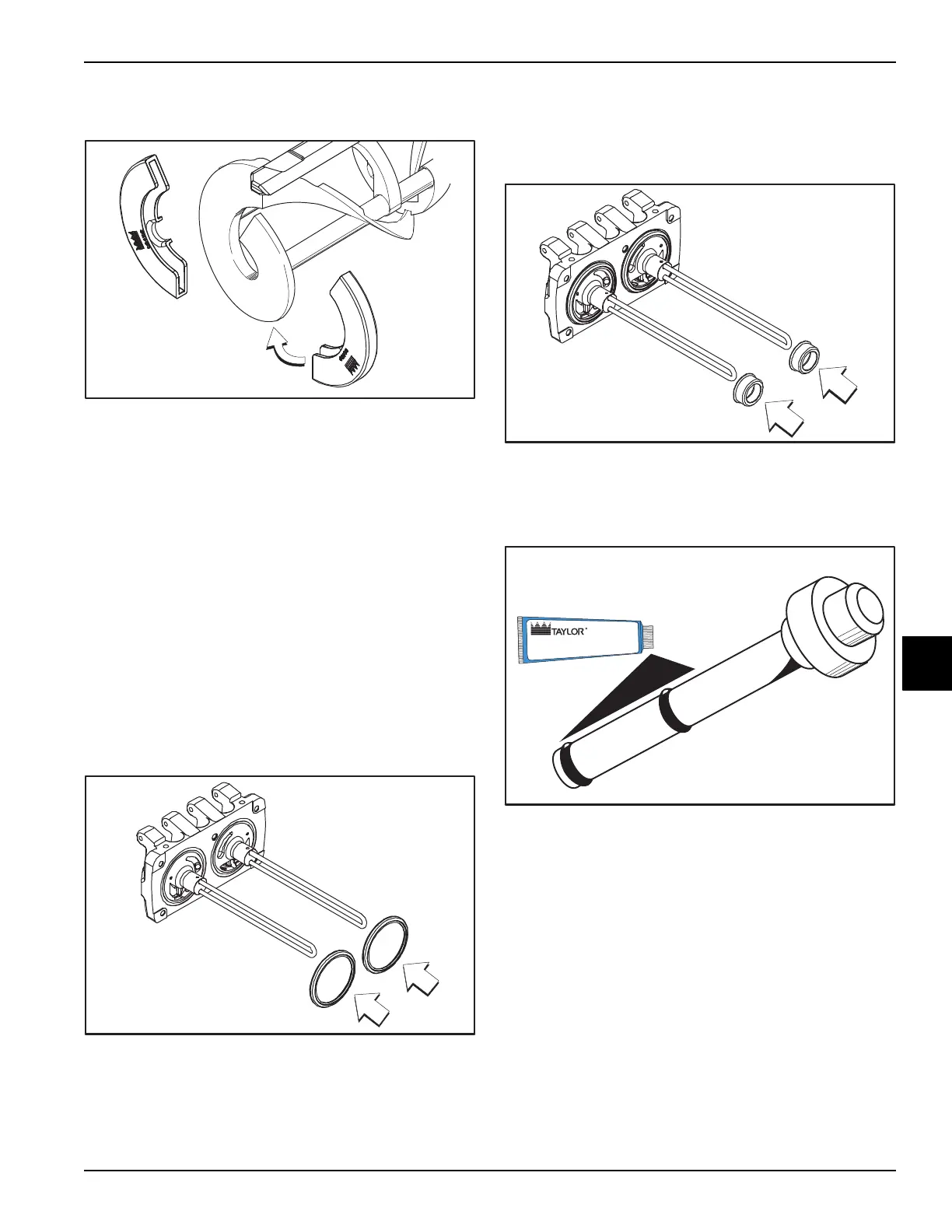

4. Slide the O-rings into the grooves on the prime plugs.

Apply an even coat of lubricant to the O-rings and the

shafts.

Figure 6-10

11067

Apply the appropriate

Taylor approved food safe lubricant.

Loading...

Loading...