Calibration-213

Service

A.

POWER

SUPPLY

AND

DISPLAY

Equipment

Required

1. Digital

Voltmeter

2.

Screwdriver

For adjustments and

test

points (TP), see

ADJUSTMENT

LOCATIONS

pullout

page

in

the

Diagrams

section.

Control Settings

POWER

DMM

VOLTS

VOLTS-mA/DIV

SEC/DIV

INPUT COUPLING

TRIGGER

INTENSITY

LEVEL-SLOPE

VOL

TS-mA/DIV

VAR

HORIZ

MGF

VAR

ON

Button

out

Button

in

1 (black

scale)

1 m

GND

INTL

AC

AUTO

Full ccw

Midrange

of

either slope

(do

not

set at midrange

of

control)

CAL

detent

CAL

detent

1.

CHECK/ADJUST

LOW-VOLTAGE

POWER SUPPLIES

a.

Connect the Digital

Voltmeter

between TP545

(+15

V)

and common.

b.

CHECK-Reading

is

+15.00 V ± 0.15

V.

c.

ADJUST

-+15

V

Adj,

R467,

for

reading

of

+15.00

V.

d. Connect the Digital

Voltmeter

between

each

of

the test points shown in Table 6-2

and

common.

e.

CHECK-Readings

are

within

tolerance shown.

REV.

B,

MAR.

1976

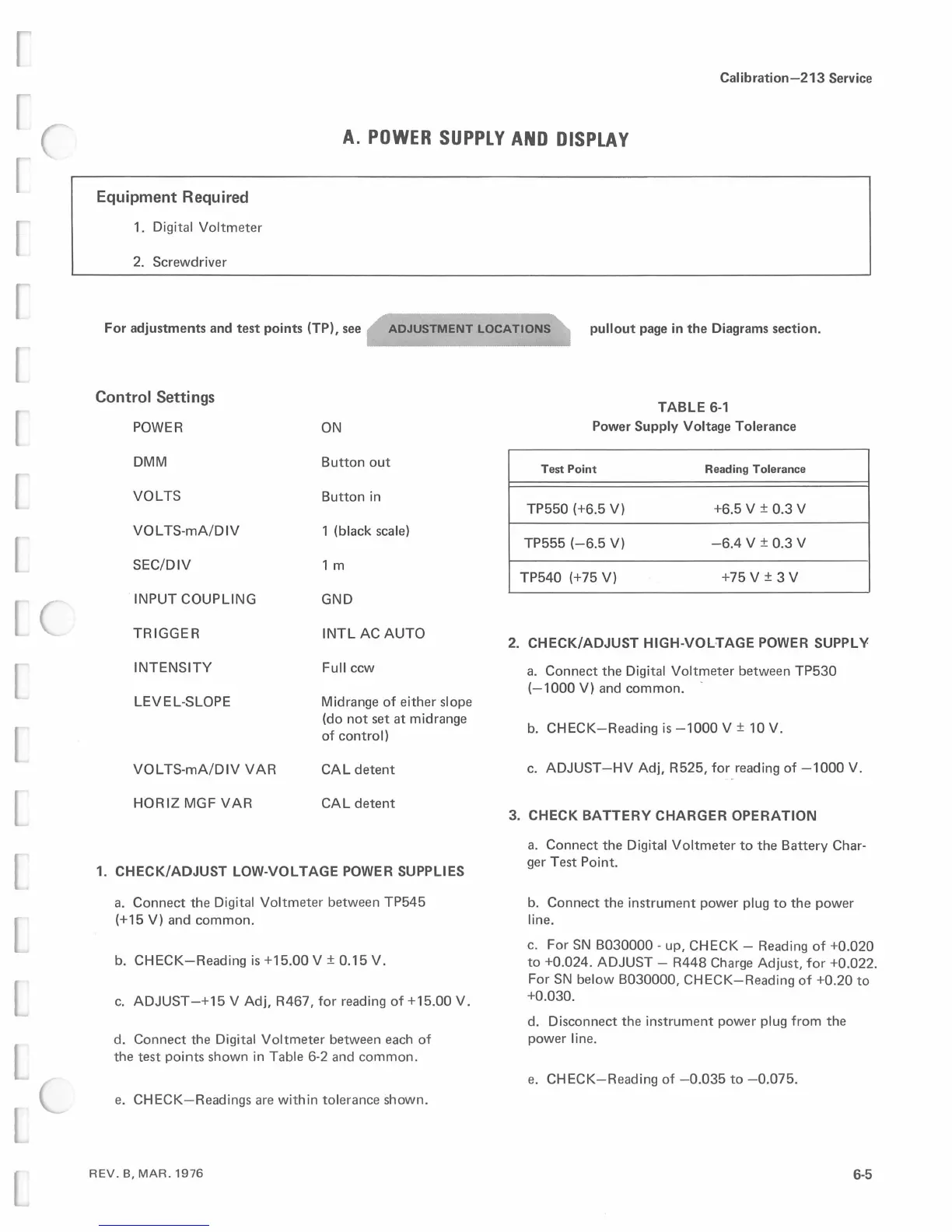

TABLE

6-1

Power Supply Voltage Tolerance

Test Point

Reading Tolerance

TP550 (+6.5

V)

+6.5 V ± 0.3 V

TP555

(-6.5

V)

-6.4

V ± 0.3 V

TP540 (+75

V)

+75V±3V

2.

CHECK/ADJUST

HIGH-VOLTAGE

POWER SUPPLY

a.

Connect the Digital Voltmeter between TP530

(-1000

V)

and

common. -

b.

CHECK-Reading

is

-1000

V ± 10 V.

c.

ADJUST-HV

Adj,

R525,

for

reading

of

-1000

V.

3.

CHECK

BATTERY

CHARGER

OPERATION

a.

Connect the Digital

Voltmeter

to

the Battery Char-

ger Test Point.

b.

Connect the instrument power plug

to

the power

line.

c.

For

SN

8030000 - up, CHECK - Reading

of

+0.020

to

+0.024. ADJUST - R448

Charge

Adjust,

for

+0.022.

For

SN

below 8030000,

CHECK-Reading

of

+0.20

to

+0.030.

d. Disconnect the instrument power plug

from

the

power line.

e.

CHECK-Reading

of

-0.035

to

-0.075.

6-5

Loading...

Loading...