Maintenance—2465B/2467B Service

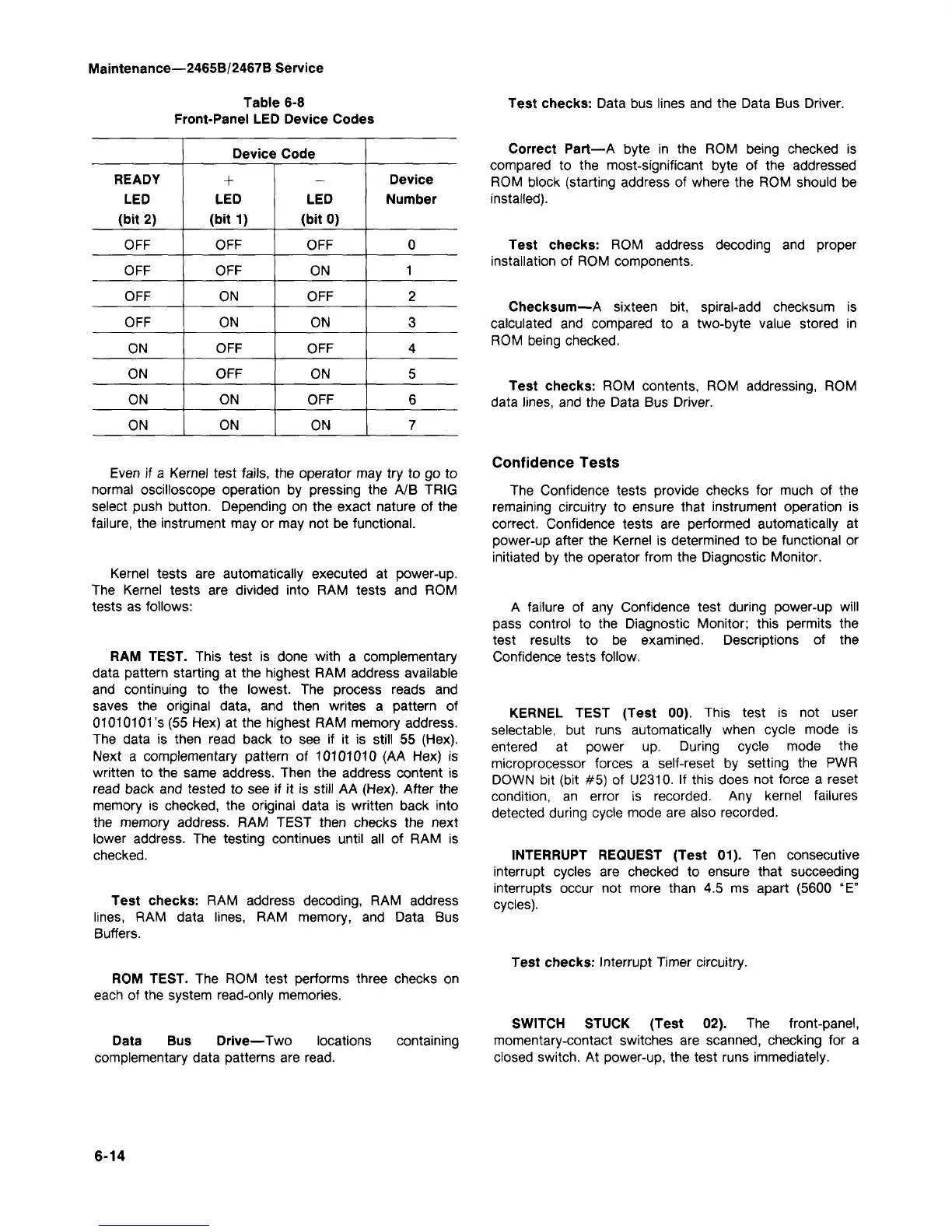

Table 6-8

Front-Panel LED Device Codes

READY

LED

(bit 2)

OFF

OFF

OFF

OFF

ON

ON

ON

ON

Device Code

+

LED

(bit 1)

OFF

OFF

ON

ON

OFF

OFF

ON

ON

LED

(bit 0)

OFF

ON

OFF

ON

OFF

ON

OFF

ON

Device

Number

0

1

2

3

4

5

6

7

Even if a Kernel test fails, the operator may try to go to

normal oscilloscope operation by pressing the A/B TRIG

select push button. Depending on the exact nature of the

failure,

the instrument may or may not be functional.

Kernel tests are automatically executed at power-up.

The Kernel tests are divided into RAM tests and ROM

tests as follows:

RAM TEST. This test is done with a complementary

data pattern starting at the highest RAM address available

and continuing to the lowest. The process reads and

saves the original data, and then writes a pattern of

01010101's (55 Hex) at the highest RAM memory address.

The data is then read back to see if it is still 55 (Hex).

Next a complementary pattern of 10101010 (AA Hex) is

written to the same address. Then the address content is

read back and tested to see if it is still AA (Hex). After the

memory is checked, the original data is written back into

the memory address. RAM TEST then checks the next

lower address. The testing continues until all of RAM is

checked.

Test checks: RAM address decoding, RAM address

lines,

RAM data lines, RAM memory, and Data Bus

Buffers.

ROM TEST. The ROM test performs three checks on

each of the system read-only memories.

Data Bus Drive—Two locations containing

complementary data patterns are

read.

6-14

Test checks: Data bus lines and the Data Bus Driver.

Correct Part—A byte in the ROM being checked is

compared to the most-significant byte of the addressed

ROM block (starting address of where the ROM should be

installed).

Test checks: ROM address decoding and proper

installation of ROM components.

Checksum—A sixteen bit, spiral-add checksum is

calculated and compared to a two-byte value stored in

ROM being checked.

Test checks: ROM contents, ROM addressing, ROM

data lines, and the Data Bus Driver.

Confidence Tests

The Confidence tests provide checks for much of the

remaining circuitry to ensure that instrument operation is

correct. Confidence tests are performed automatically at

power-up after the Kernel is determined to be functional or

initiated by the operator from the Diagnostic Monitor.

A failure of any Confidence test during power-up will

pass control to the Diagnostic Monitor; this permits the

test results to be examined. Descriptions of the

Confidence tests follow.

KERNEL TEST (Test 00). This test is not user

selectable, but runs automatically when cycle mode is

entered at power up. During cycle mode the

microprocessor forces a self-reset by setting the PWR

DOWN bit (bit #5) of U2310. If this does not force a reset

condition,

an error is recorded. Any kernel failures

detected during cycle mode are also recorded.

INTERRUPT REQUEST (Test 01). Ten consecutive

interrupt cycles are checked to ensure that succeeding

interrupts occur not more than 4.5 ms apart (5600 "E"

cycles).

Test checks: Interrupt Timer circuitry.

SWITCH STUCK (Test 02). The front-panel,

momentary-contact switches are scanned, checking for a

closed switch. At power-up, the test runs immediately.

Loading...

Loading...