Operating Instructions—465B Service

MOUNTING PROCEDURE

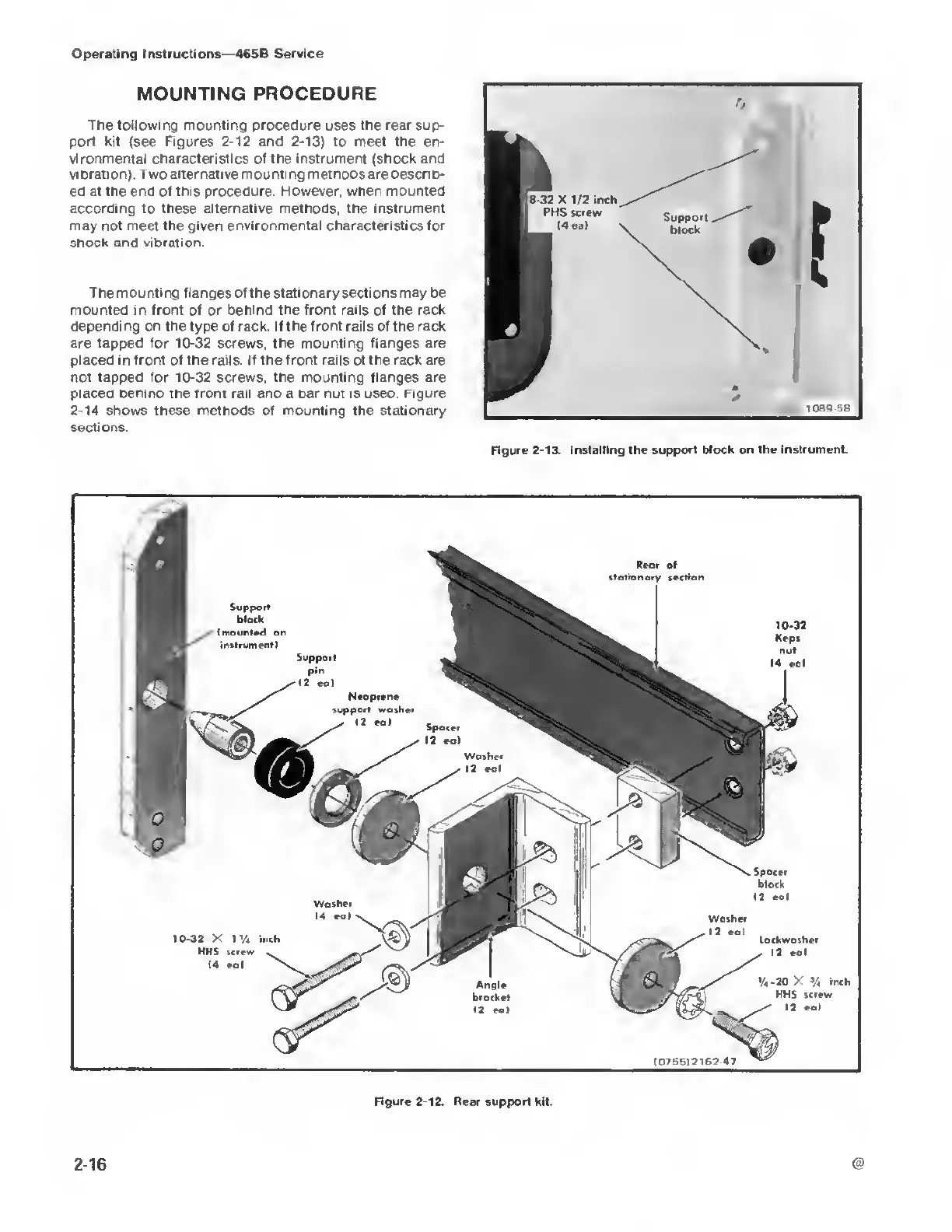

The following mounting procedure uses the rear sup-

port kit (see Figures

2-12

and 2-13) to meet the en-

vironmental characteristics of the instrument (shock and

vibration). Two alternative mounting methods are describ-

ed at

the

end of

this

procedure

However, when mounted

according to these alternative methods, the

instrument

may not meet the given

environmental

characteristics for

shock and vibration.

The mounting flanges

of

the stationary sections may be

mounted in front of

or

behind the front rails of the rack

depending on the type of rack. If the front rails of the rack

are tapped for

10-32

screws, the mounting flanges are

placed in front of the rails. If the front rails of the rack are

not tapped for

10-32

screws, the mounting flanges are

placed benina the front rail ana a oar nut is usea. Figure

2-14

shows these methods of mounting the stationary

sections.

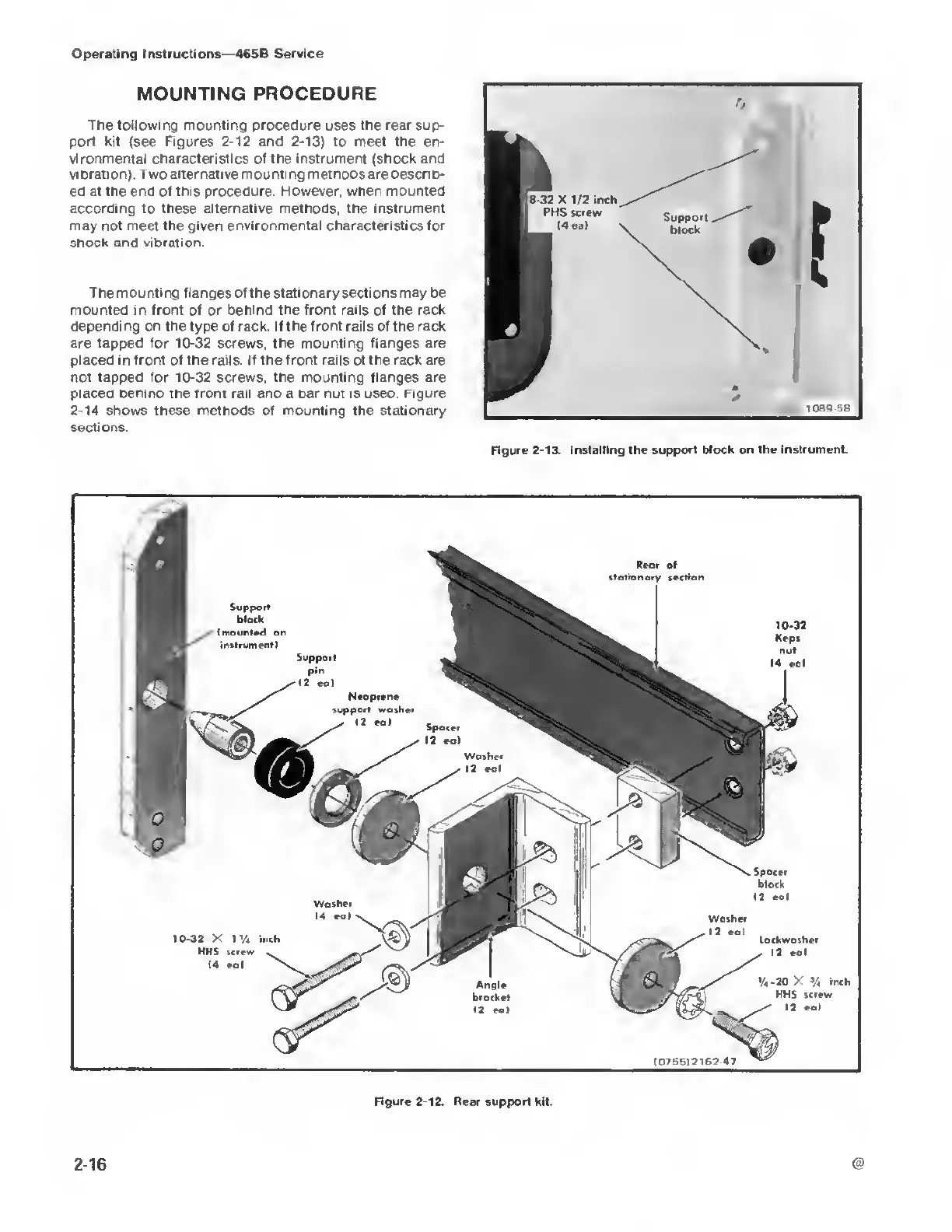

Figure

2-13.

Installing the support block on the

instrument.

Washer

14 eal

10-32

X

1V4

inch

HHS screw

14

eal

on

instrument!

Rear

of

section

10-32

Keps

nut

Spacer

block

12 eal

Washer

12

eal

Lockwasher

(2

eal

-20

X

%

inch

HHS screw

Figure 2-12.

Rear support kit.

2-16

Loading...

Loading...