3 Technical data

34 TL80

3.15 Fork lift attachment

Fork-arm connection in compliance with ISO/FEM Class 2 Form B, DIN 15 173 / ISO 2328 respectively

Width of fork carrier mm 1,240

Length of forks mm 1,100

Fork cross section mm 100x45

Max. stacking height mm 3,070

The payloads are determined in compliance with DIN 24094 / ISO 14397-1 respectively with a stability factor

of 1.25 or 80% of the tipping load and the machine moving over level ground.

The payloads are valid for the machine fitted with 405/70 R 18 SPT9 tires and the equipment condition as

described in compliance with ISO 6016.

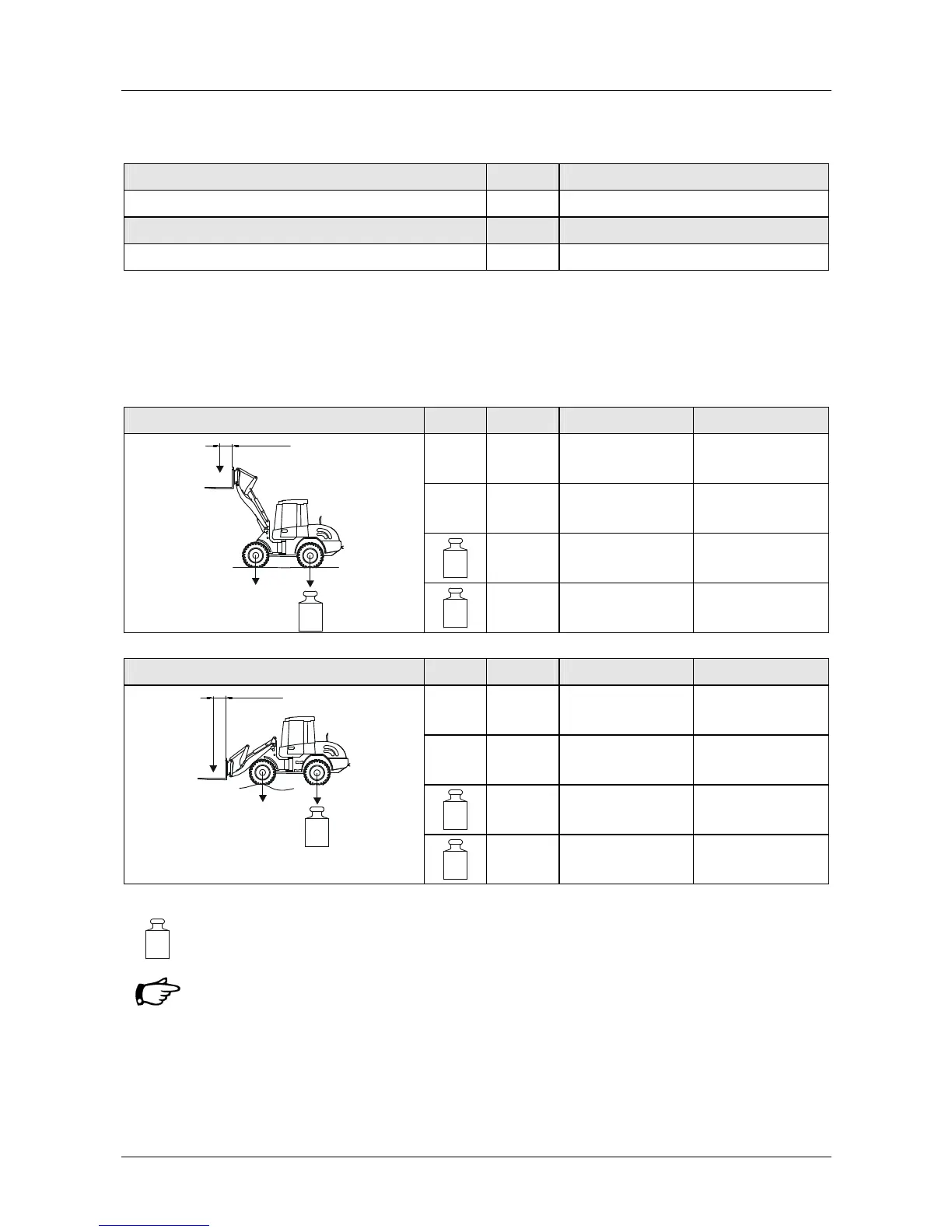

Total lift range

S=2.0 S=1.25

kg 1,280 2,050

lbs 2,820 4,520

kg

lbs

kg 1,400 2,250

500mm

19,7inch

+0,5bar

+7,3psi

+

kg

lbs

kg

lbs

lbs 3,100 4,960

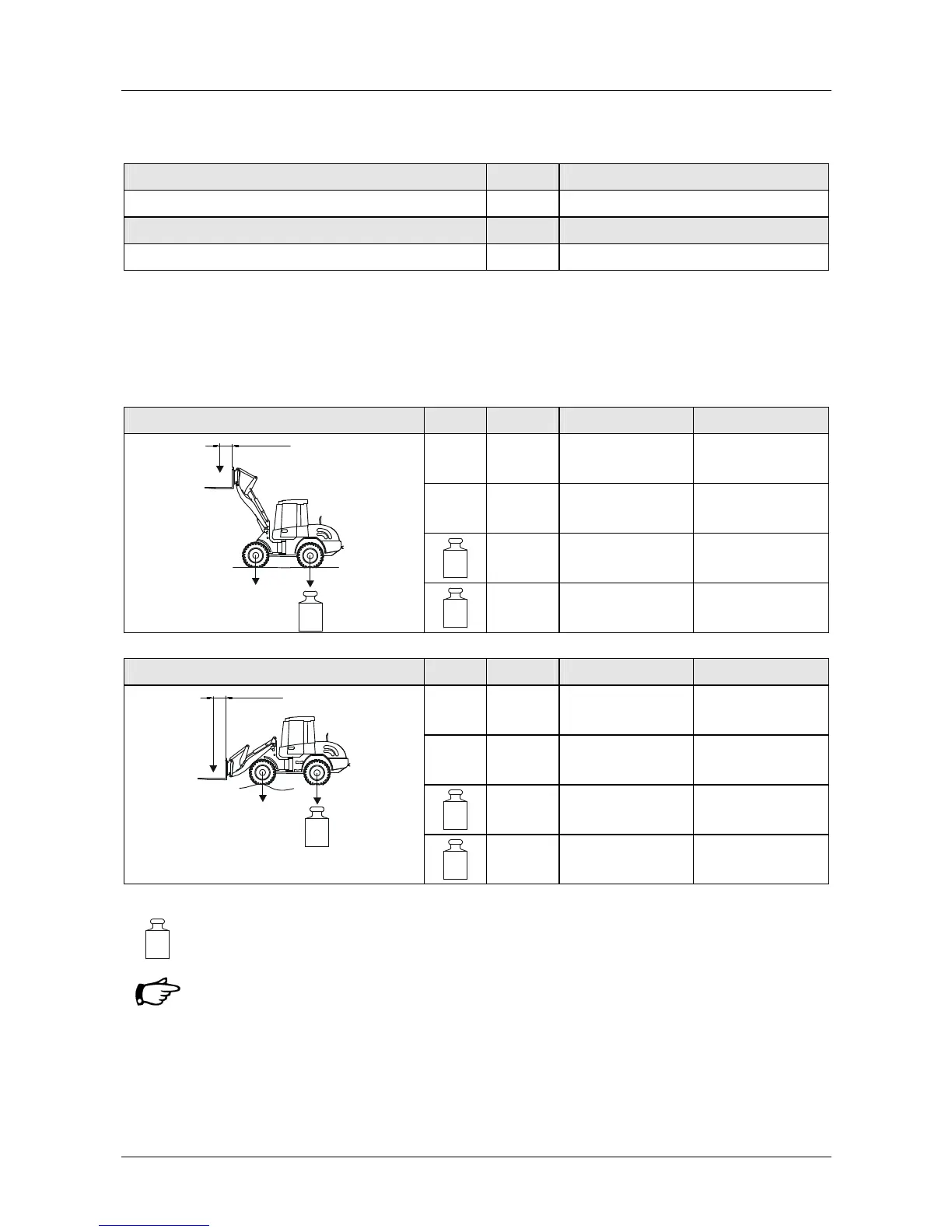

Transport position

S=1.67 S=1.25

kg 1,720 2,300

lbs 3,790 5,060

kg

lbs

kg 1,870 2,500

500mm

19,7inch

+0,5bar

+7,3psi

+

kg

lbs

kg

lbs

lbs 4,120 5,500

kg

lbs

If screw-on rear axle weights or rear tires with hydroinflation are used.

During fork lift operations, the tire pressure of the front wheels must be increased by at least

0.5 bar.

Loading...

Loading...