Structural Maintenance

143

Reassembly

1. Coat the edges of the oil seals with a gasket

sealant.

2. Using a suitable tool, install the seals in the

end caps. Fill the space between the seal lips

with grease. Install the assembled end cap

(seal and bearing race installed) on the oil

level plug end of jackshaft housing.

3. Place the oil sling retainer on the shaft. If the

bearings were removed from the shaft, place

the oil sling retainer on the shaft while

installing the bearings. If the bearings were

not removed from the shaft, press the oil sling

retainer onto the shaft through the opening in

the top of the oil sling retainer.

4. Use a tie band or a hose clamp as tool to

compress the oil sling retainer enough to fit

inside the jackshaft housing.

5. Install the shaft into the jackshaft housing

with oil sling retainer on the shaft with

bearing. Align the opening in the oil sling

retainer with the air vent opening in the top of

the jackshaft housing.

6. Use a punch and hammer to tap the oil sling

retainer into the jackshaft housing until it is

centered beneath the air vent opening and past

the housing lip that holds the outer race.

7. Remove the tie band or hose clamp.

8. Install the remaining end cap.

9. Torque the bolts to 10 ft-lb (13.6 N•m).

10. Check end play of the shaft with a dial

indicator. End play should be between 0.001

to 0.005 in. 0(.025 to 0.127 mm). Change

shims if necessary.

11. Pour 3.5 oz (104 ml) of fanshaft oil P/N

203-278 into the jackshaft housing.

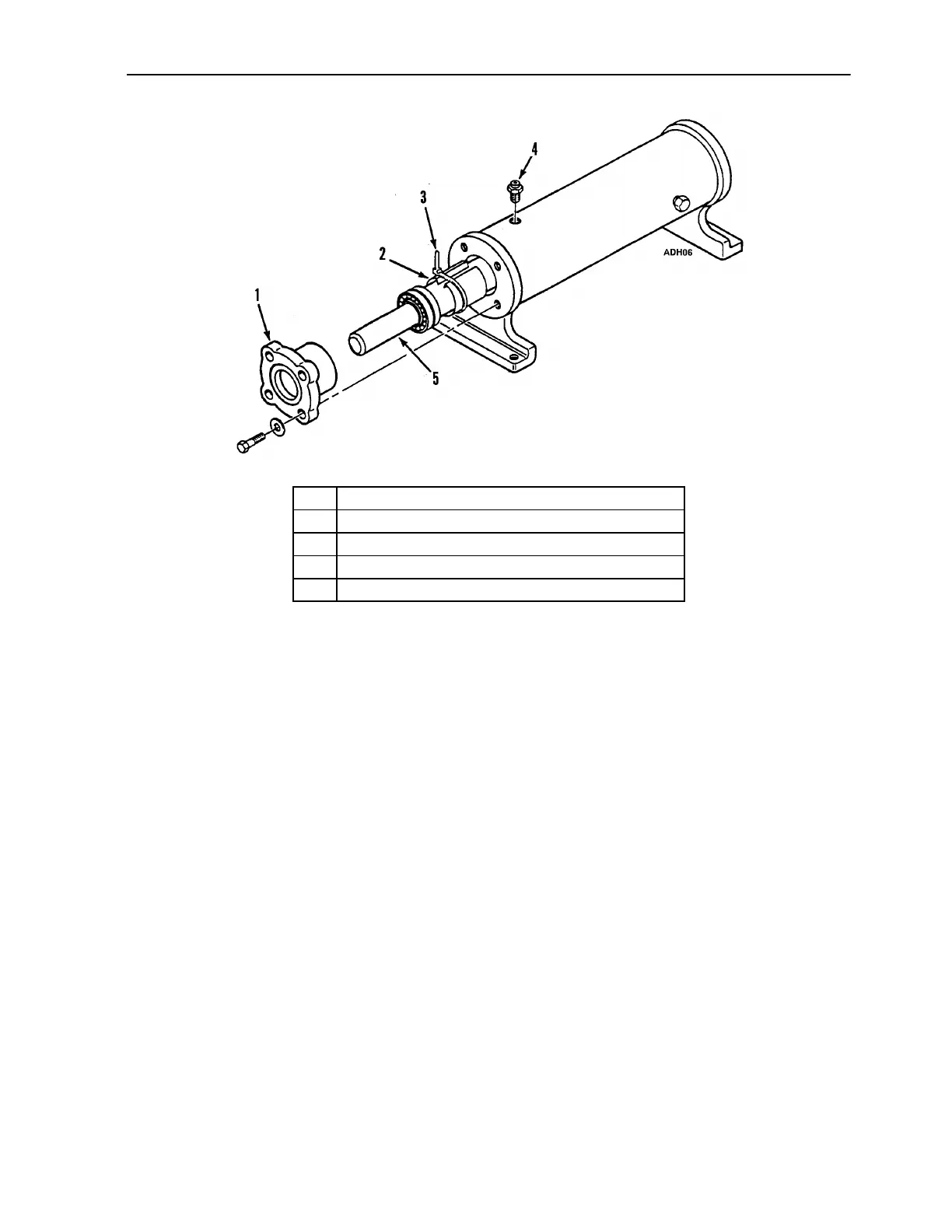

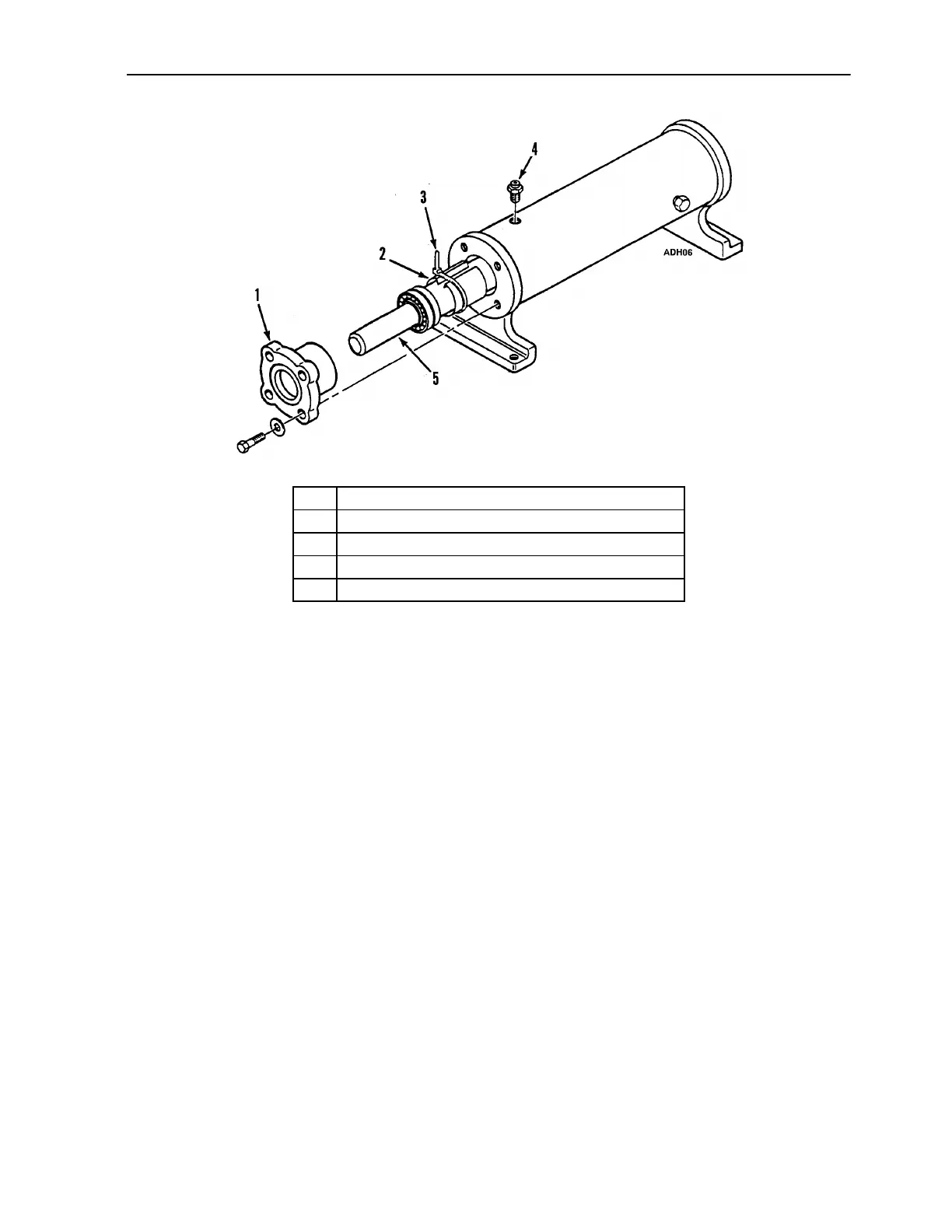

1. End Cap

2. Oil Sling Retainer

3. Tie Band

4. Air Vent (P/N 55-6417)

5. Shaft

Figure 66: Installing Oil Sling Retainer

Loading...

Loading...