Structural Maintenance

146

5. Install the retainer cap assembly over the

shaft, and then install the bolts.

6. Torque the bolts in a criss-cross pattern in

equal steps to 80 in-lbs (9.04 N•m).

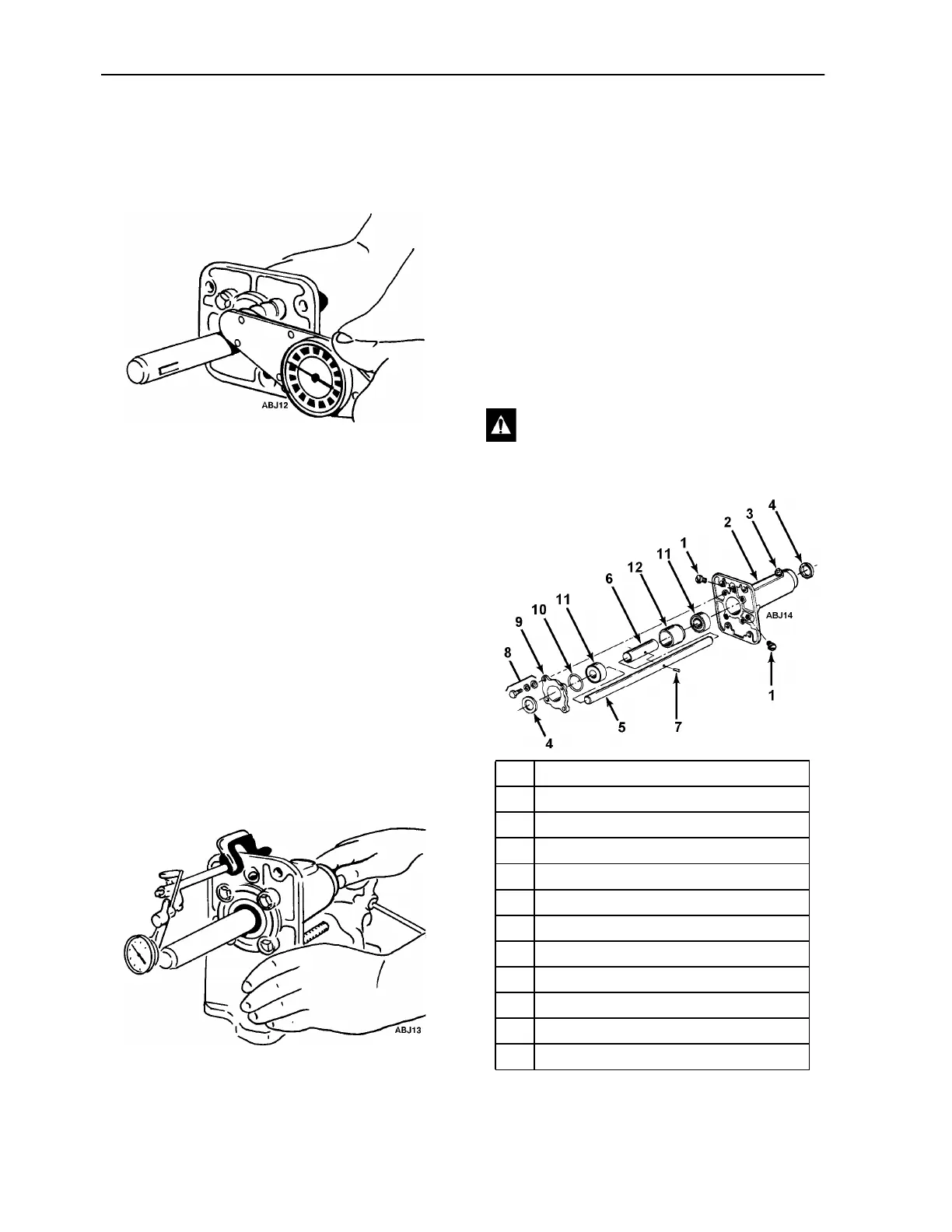

Figure 75: Torquing Retainer Plate Bolts

7. Lock the assembly in a vise and set up a dial

indicator to read the end play. To measure the

end play, rotate the shaft while pushing in one

direction, and set the dial indicator to 0. Now

rotate the shaft and pull in the opposite

direction while reading the dial indicator. The

end play should be 0.001 to 0.005 in. (0.025 to

0.127 mm). If the end play is incorrect, use

different shims to obtain the correct end play.

Shims available from the Service Parts

Department:

Figure 76: Checking End Play

8. After the correct end play is obtained, add

grease for the bearings.

NOTE: Use ONLY Thermo King special

fanshaft grease (P/N 203-278) in this assembly.

Lock the assembly in a vise with the vent

facing up. Pour grease through the top plug

until it runs out of the side hole. The assembly

holds 2.2 oz (65 ml). Check the condition of

the o-ring used on the plugs and replace if

necessary. Install top and side plugs. Clean up

any spillage.

9. Place the assembly on the workbench with the

vent up. Rotate the shaft by hand. The shaft

should be free enough to rotate without having

to hold the housing.

0.020 in. (0.500 mm) P/N 99-4231

0.007 in. (0.177 mm) P/N 99-2902

0.005 in. (0.127 mm) P/N 99-2901

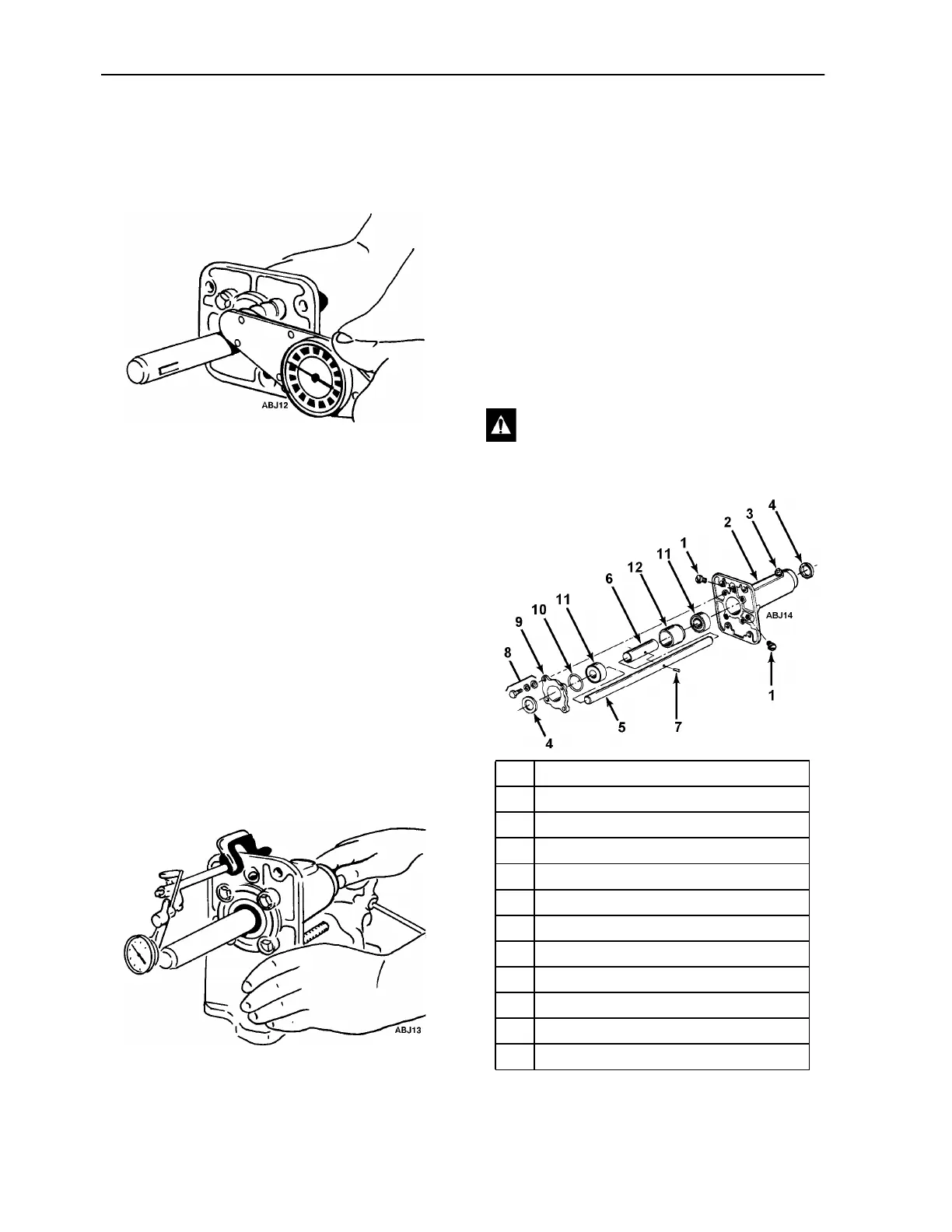

CAUTION: When installing the fanshaft

assembly, make sure that the vent is

mounted facing up.

1. Oil Plug Screw with O-ring

2. Housing

3. Breather Vent

4. Oil Seal

5. Shaft

6. Sleeve

7. Pin

8. Screw with Flatwasher and Lockwasher

9. Cap and Shims

10. O-ring

11. Roller Bearing

12. Splash Guard Tube

Figure 77: Fan Shaft Assembly

Loading...

Loading...