3. OPERATION

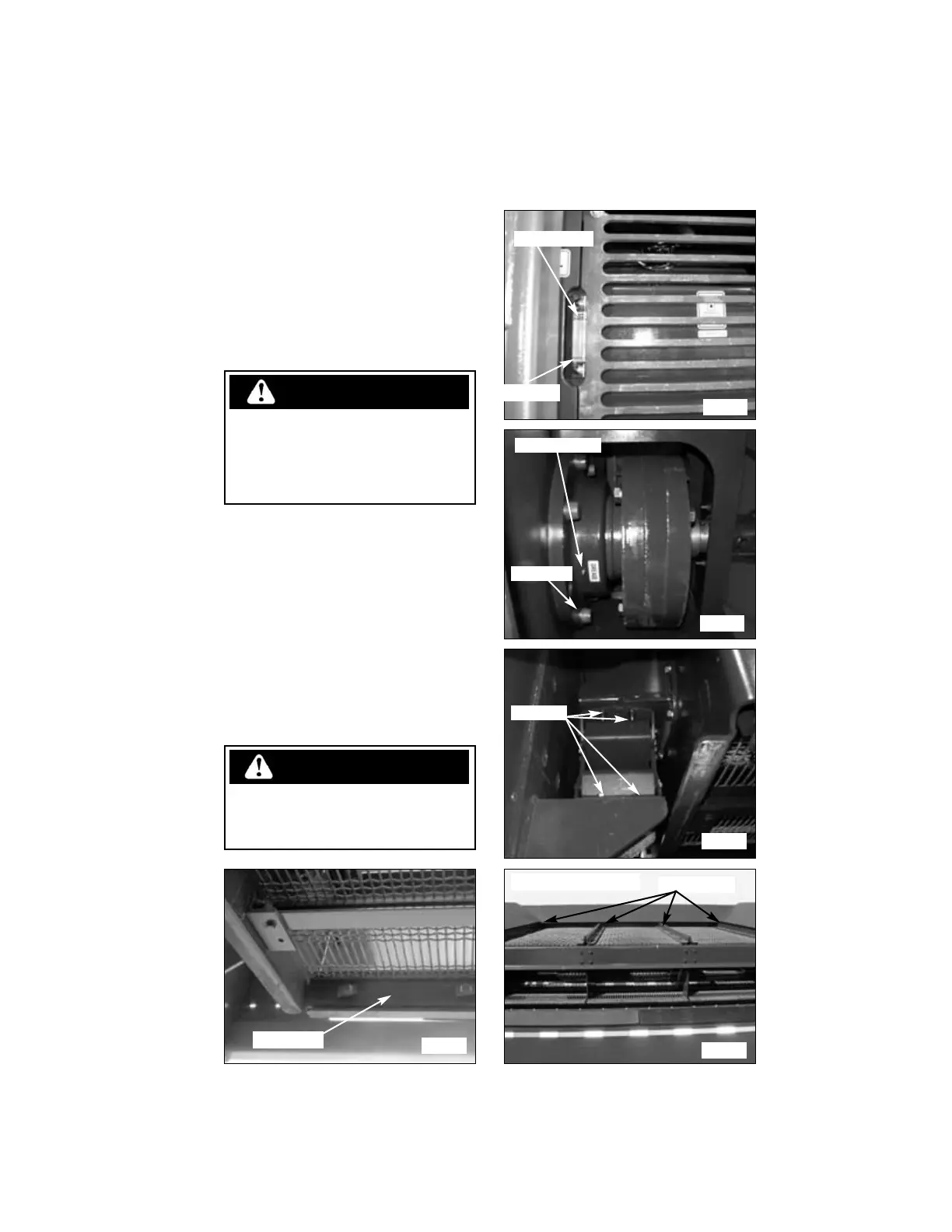

Hydraulics:

1. Check the fluid level. Add 10W30 motor oil

as required to bring fluid level in the middle

of the site gauge (fig. T90021). Make sure

the filler cap is secure.

2. Check all hydraulic hoses for chafing, bulges

and leaks. Replace immediately if defects are

found.

3. Verify hydraulic controls are in the neutral

position before starting the engine.

Shakerhead:

1. Check shaker suspension mounting hardware

for tightness (fig. T90023). Follow the proce-

dure in section 4.

2. Check shaker suspension mounts for cracks

(T90023). If cracks are found, consult your

local dealer.

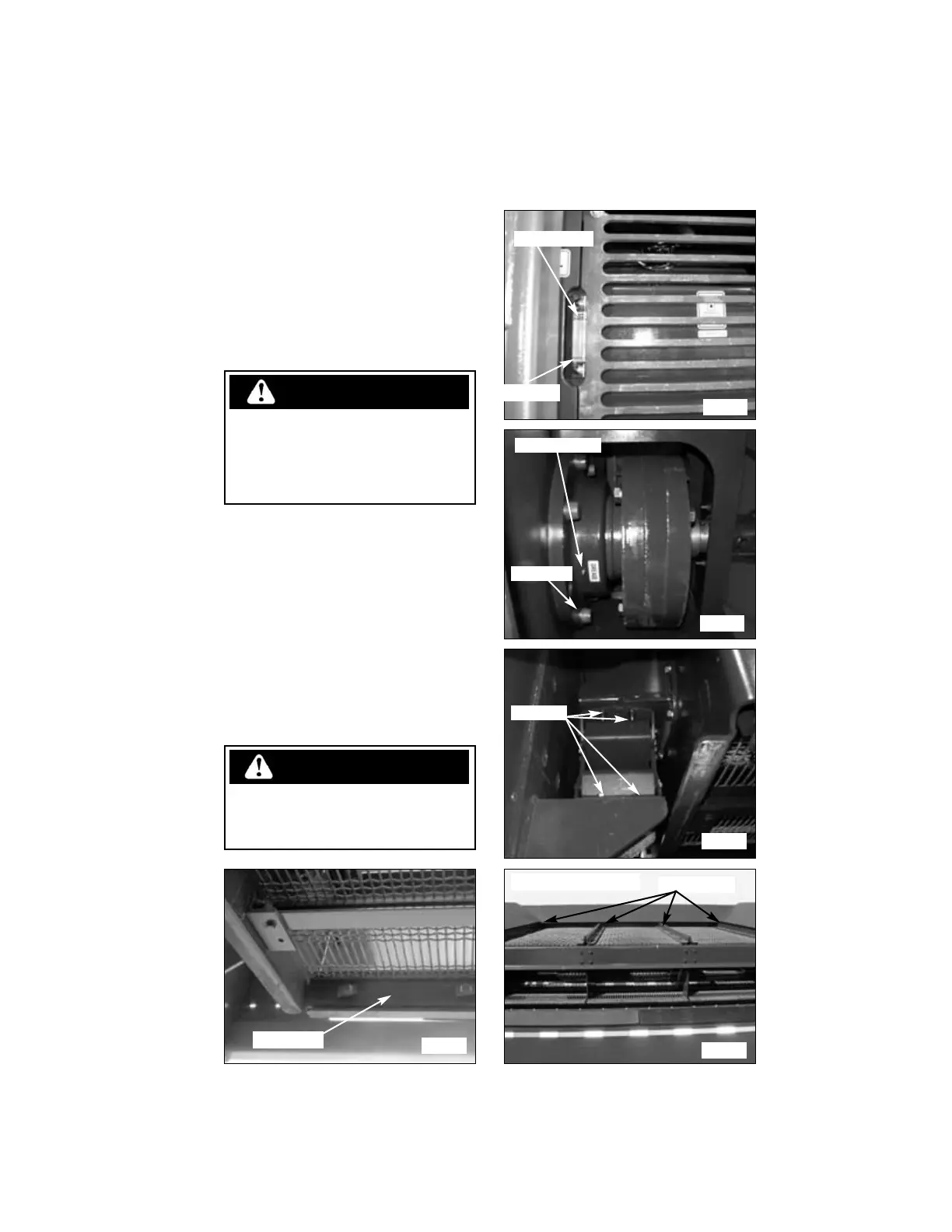

3. Verify there is no debris on the shaker

screens and check for bystanders before

start-up.

4. Check the shaker screens and holddown

mounting hardware for proper tension (fig.

T90082 & T90013). See section 4.

Never repair or tighten hydraulic hoses or

fittings while the machine is running. Fluid

under pressure can penetrate the skin and

cause serious injury.

WARNING

Verify there is no debris on the shaker

screens and check for bystanders

before start-up.

WARNING

15

Grease bearings

Check bolts

Low level

Check bolts

Operating level

T90021

T90022

T90023

Shaker deck / head

T90013

Holddown

T90082

Holddowns

Loading...

Loading...