4. MAINTENANCE

52

4.7 AS REQUIRED SERVICE

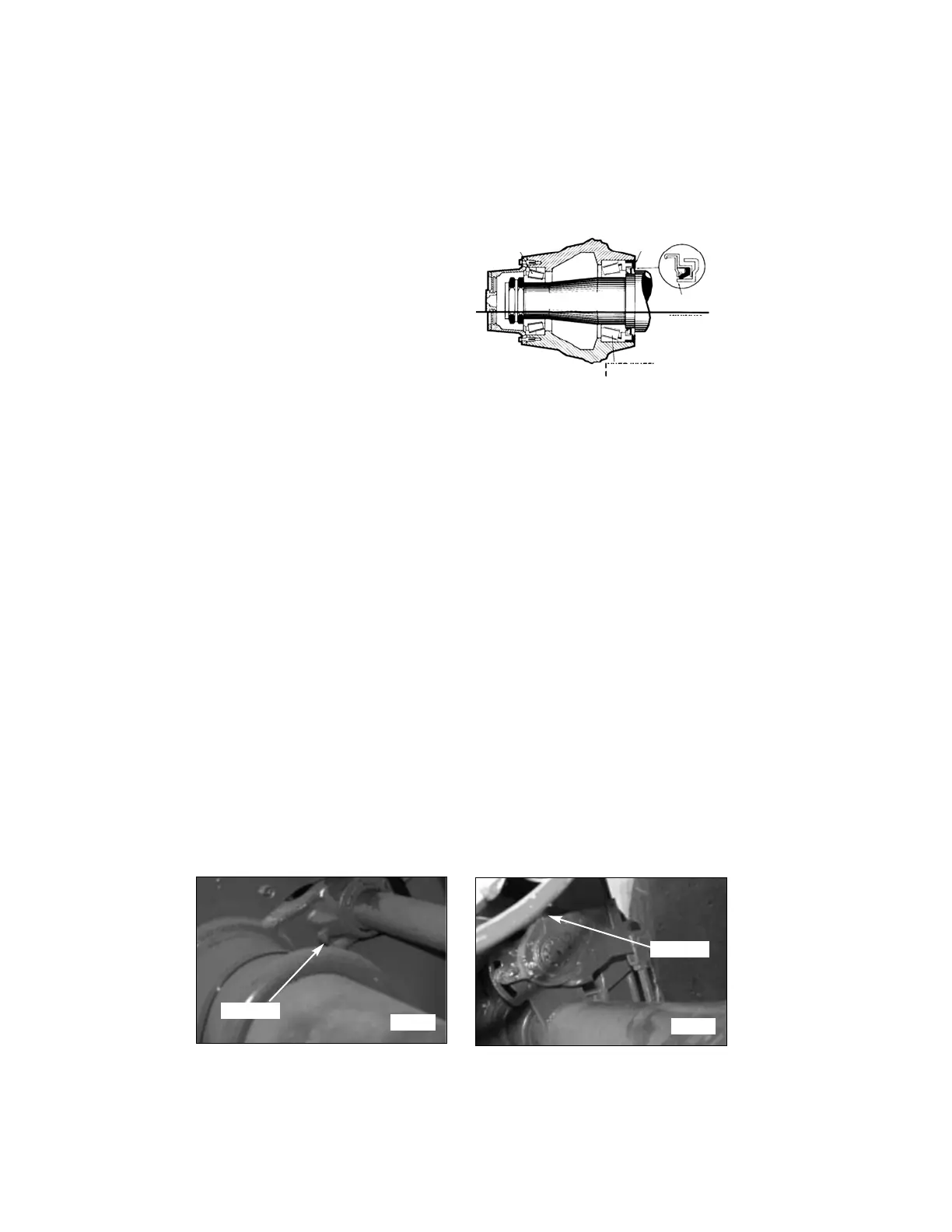

4.7C Wheel Bearing and Seal

Maintenance

Visually inspect the oil seal for leaks

and fill to the full oil level line (T90085).

Wheel Bearing Adjustment

1. Lubricate the wheel bearing with

clean lubricant of the same type used in the

axle sump or hub assembly.

2. Tighten the adjusting nut to a torque

of 200 ft. lbs., while rotating the wheel.

3. Back the adjusting nut off one full

turn.

4. Tighten the adjusting nut to a final

torque of 50 ft. lbs., while rotating the

wheel.

5. Final back off of adjustment nut-1/4

turn and install lock washer to nearest hole.

6. Torque jam nut to 200-300 ft. lbs. (if

nut size less than 2 5/8") or 300-400 ft. lbs.

(if nut size greater than 2 5/8").

7. Measure end play with a dial indica-

tor, ensure it is .001" - .005".

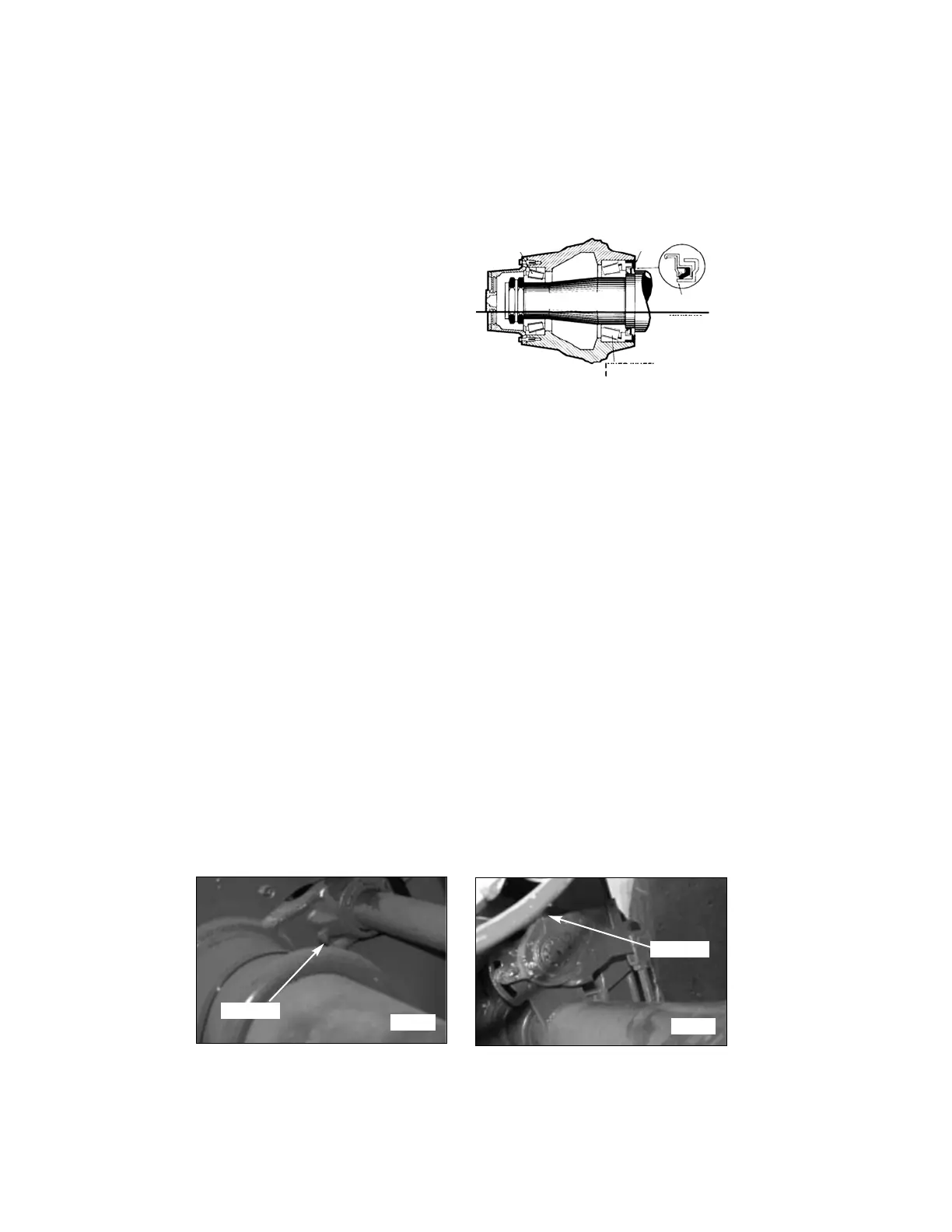

4.7D Brake Maintenance

Lubricate camshaft slack adjusters every

5,000 miles. The following service is rec-

ommended every 10,000 to 25,000 miles.

T90085

Inner Wheel

Bearing

Minimum

Oil Level

Outer Wheel

Bearing

Oil Seal

Axle Ring

T90086

T90087

Grease Zert

Grease Zert

Loading...

Loading...