31

4. MAINTENANCE

4.3 DAILY SERVICE

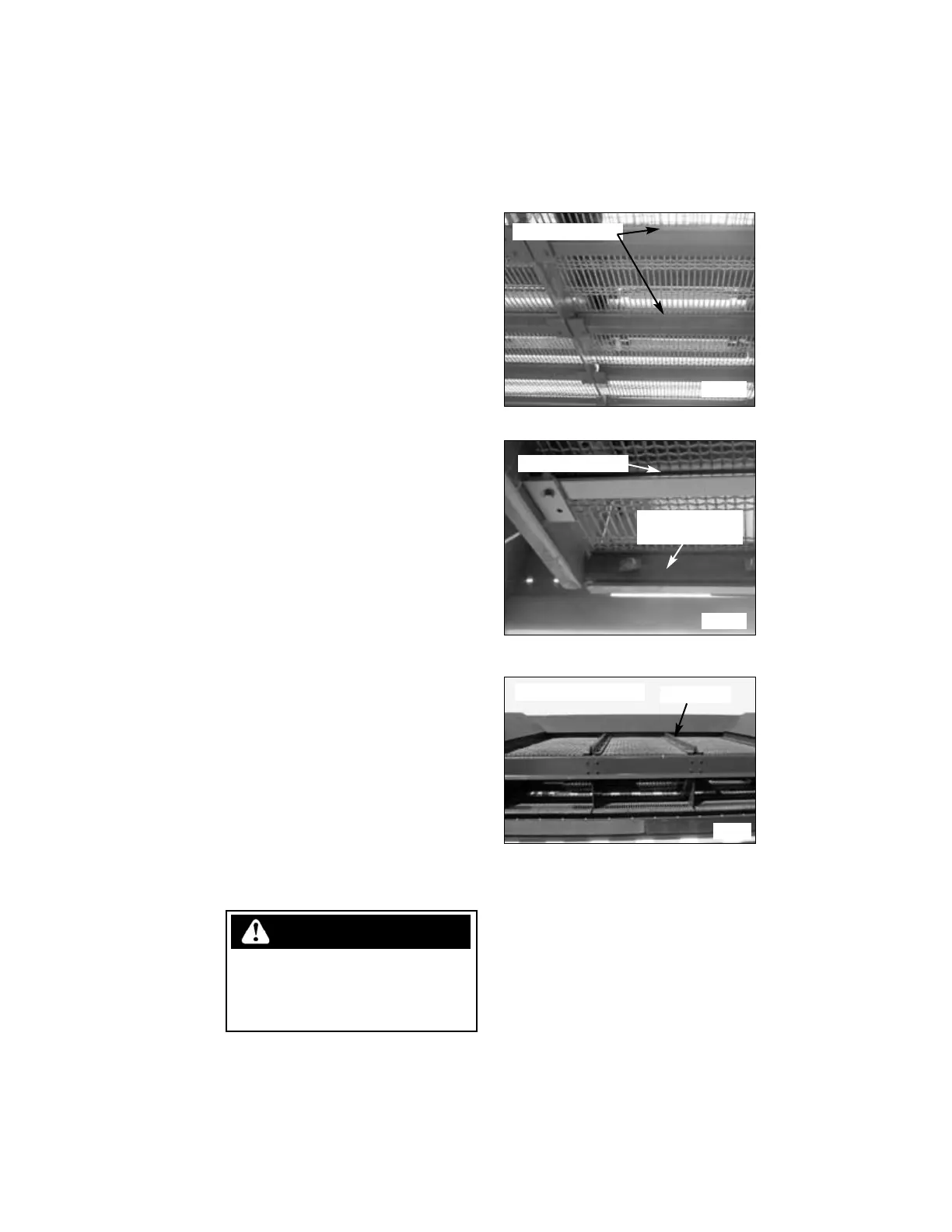

4.3A Screen Tension

To prevent premature screen or crown

bar rubber wear:

Every 4 hours of operation, check the

crown bar rubber on the top and bottom

screens. (T90081 &T90082) Make sure it is

intact and not damaged. If necessary,

replace.

Every 4 hours, torque the bolts retain-

ing the screens to the deck. Start from the

middle, tighten the bolts in a criss-cross

pattern, torque the top screen to 466 lbs.

(632 Nm), and torque the lower screen to

120 lbs. ft (163 Nm) (T90013).

See section 5.3 for torque specifications

per bolt size.

Ensure the screens are tight against the

crown bar rubbers. If necessary, tighten the

bolts further, in 25 lbs./ft. (34 Nm) incre-

ments, until the screen is tight against the

crown bar rubbers.

Start the engine and engage the shaker

to verify. (Refer to section 3 for operating

instructions). The screens must not bounce

freely on the crown bar rubbers. This will

decrease the life of the screens. You will

notice if the screens are loose by the rap-

ping noise they will make. If necessary,

tighten the bolts further, in 5 lbs. / ft. (6.8

Nm) increments, until the screen is tight

against the crown bar rubbers and they do

not bounce when the shaker is engaged.

When performing maintenance, ensure the

engine is off and the ignition key is

removed to prevent accidental start up.

WARNING

Shaker deck / head

T90013

T90082

Holddown

Crown bar rubber

T90081

Crown bar rubber

Bottom wire cloth

holddown

Loading...

Loading...