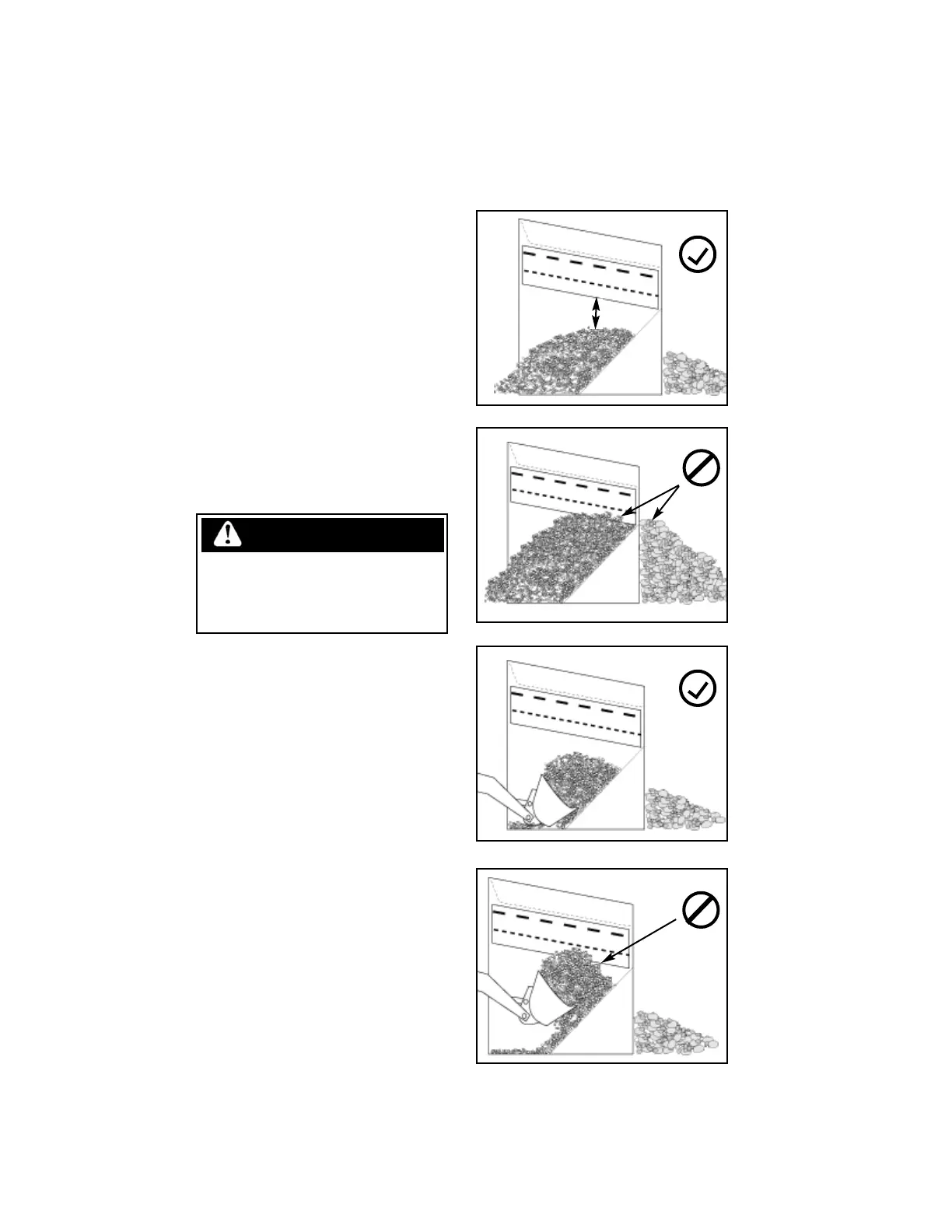

3. OPERATION

3.5C Removing Finished Material

After each load is placed into the hop-

per, check the finished and tailing piles.

Allow adequate area to retrieve finished

material from under the hopper and shaker

deck area (fig. S0004).

For best efficiency, allow at least a full

bucket of material to accumulate before

retrieving.

Do not allow the product to pile up

around the shaker deck area (fig. S0005).

This will impede the shaker action and

could result in serious damage to the shaker

deck assembly.

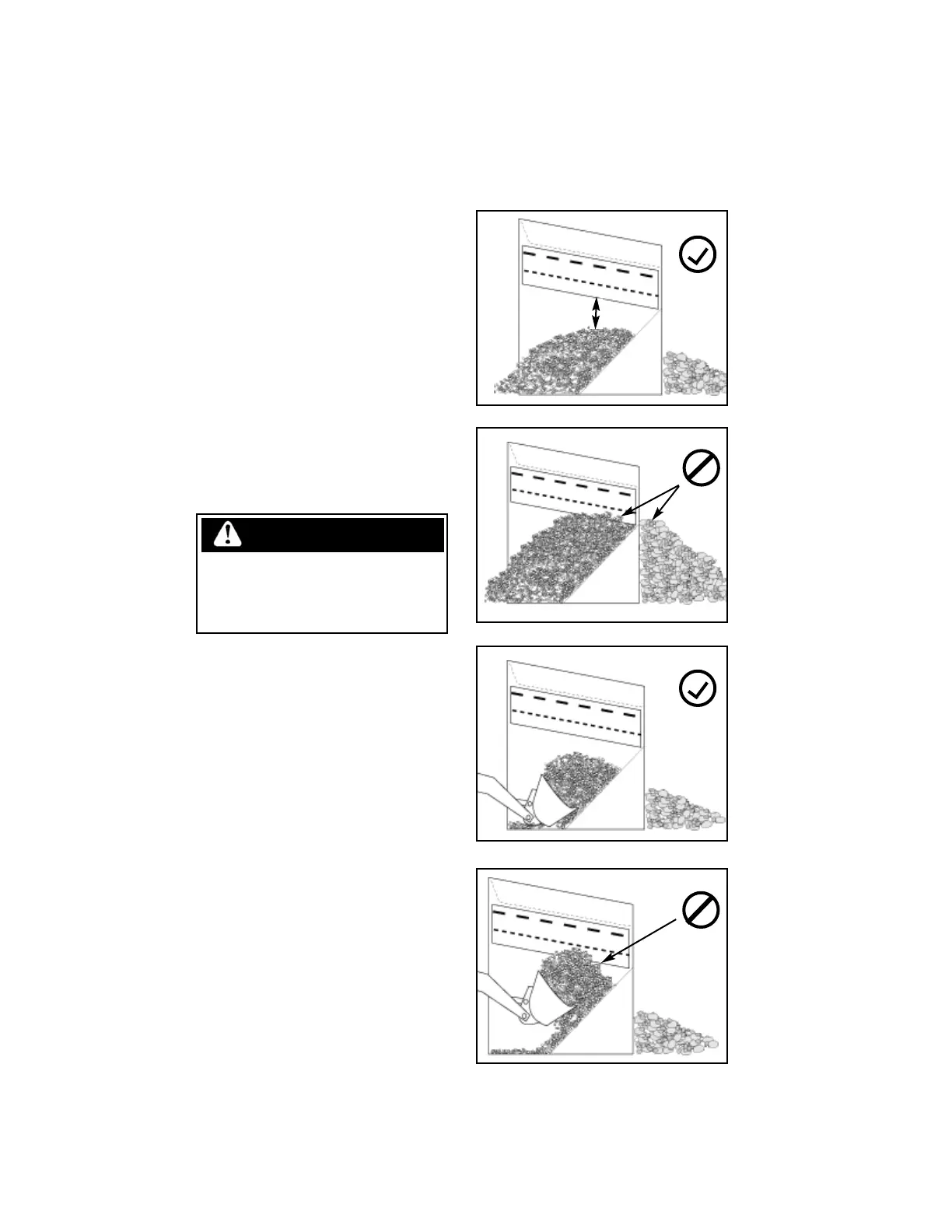

Retrieve finished material from under

the high hopper side area (fig. S0006).

Drive into the material with the bucket low.

Use the screener as a back stop, curling the

bucket before you contact the deflector

plate (fig. S0006).

Do not raise the bucket excessively as

to contact the shaker deck assembly (fig.

S0009). Serious damage may occur.

Allowing excessive material to pile up

under the shaker deck may cause serious

damage to the machine.

CAUTION

22

S0004

S0005

S0006

S0009

Loading...

Loading...