6. REPLACEMENT SCREENS

D. Ordering Information

Top Deck, Side Tension

Flat Wire Cloth:

Bottom Deck, End Tension 82-1/4" OH/OB x 41" sections (3 pieces required); material 1/4"

diameter wire, opening 3/4"x 5" with slots parallel to 82-1/4"

dimension. Heavy duty edge type M; 1-1/4" bend @ 180 degree w/

5/8" throat.

OH - Outside Hook Dimension

Keep in mind the clear opening between the top deck and the bottom deck determines the maximum size

wire cloth opening you can use for the top screen. This is if you are using both decks to achieve your

end product. The maximum size wire cloth opening you can use with the ProTough 900 would be 7" if

using both top and bottom screens. Anything 7" or larger, the material could get lodged between the

cross pipe and the bottom screen, which could damage both the shaker head and the bottom screen. If

you are using only one screen then you can determine the size of the material you require.

For the general rule of thumb - Metal Reinforced Edge (MRE) or edge type M is used on wire diameter

that does not exceed 0.312" and the Bent Edge (BE) is used on wire diameter that is greater than 0.312".

So if you prefer one edge or the other please state.

75

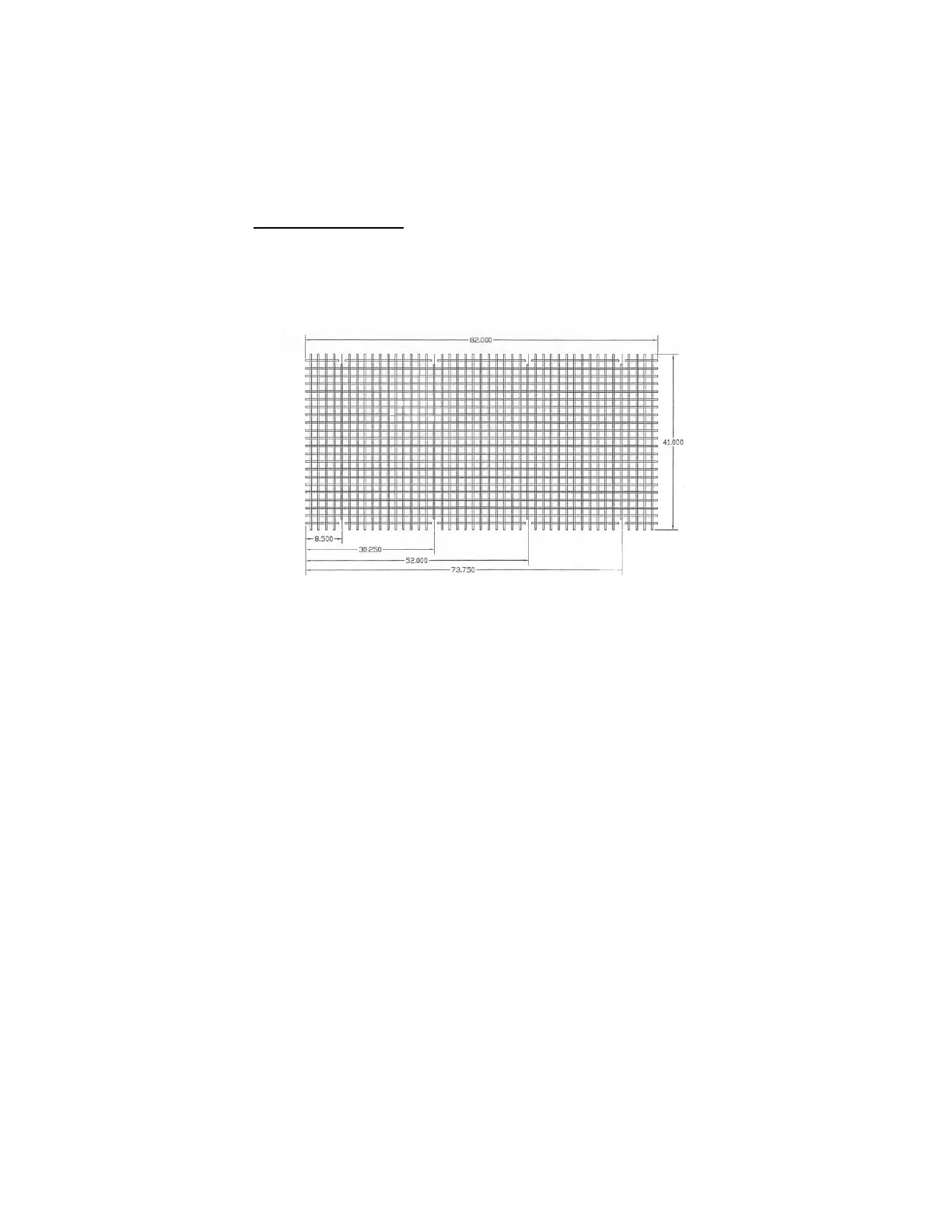

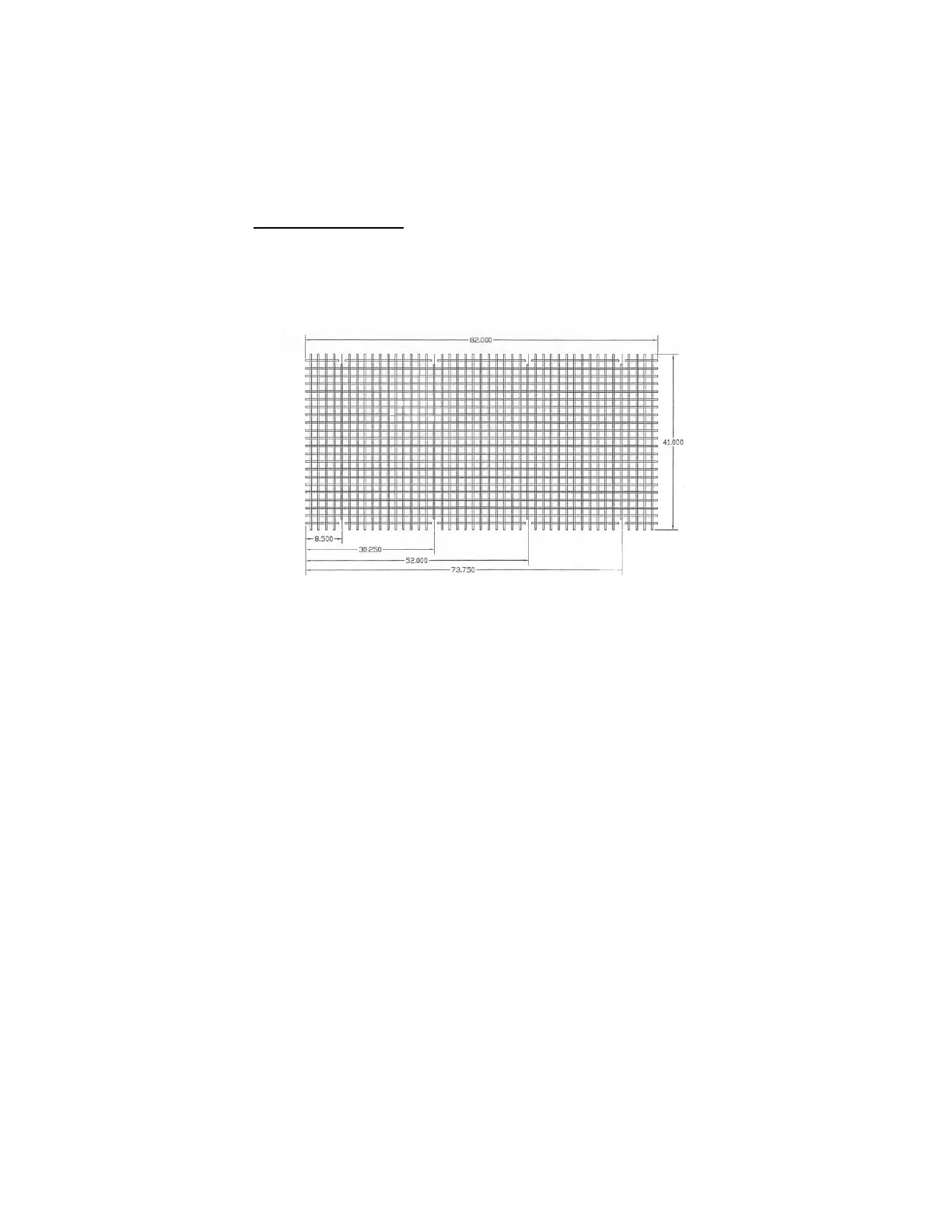

82" x 41" sections (3 pieces required); sheared with notches for clamp-

ing system. 1-1/2" x 1-1/2" clear opening x 3/8" diameter of wire

material. With special tack welded notches @ 8-1/2"; 32-1/4"; 52",

73-3/4" both sides as per sketch.

T90105

Loading...

Loading...