3. OPERATION

3.5B Loading Procedure

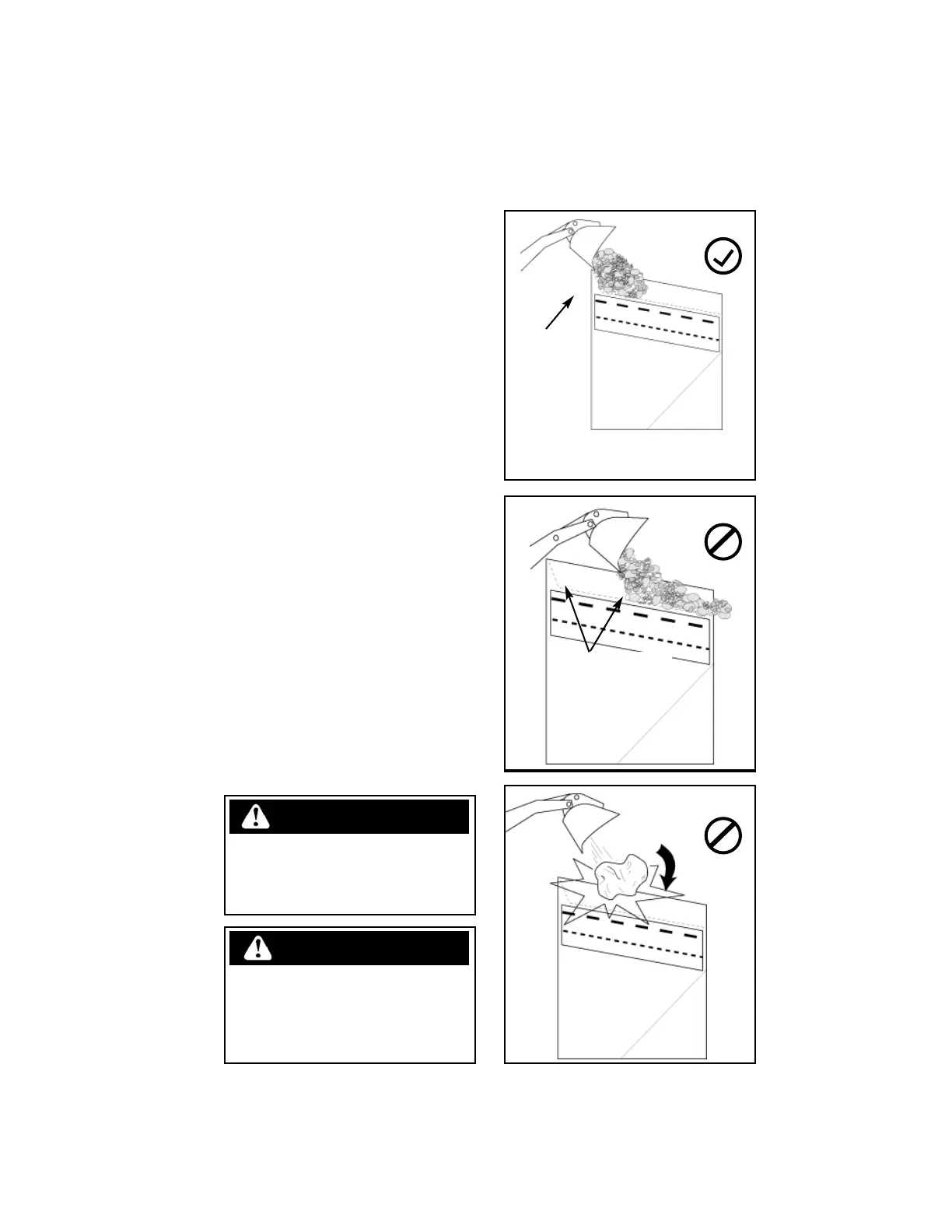

When loading material into the hopper,

keep the bucket as low as possible (fig.

S0010). Allow the material to slide down

the high side of the hopper plate onto the

top screen deck.

Check tailings for size. If you find good

material mixed in with the tailings, try

slowing the feed rate (dump) into the hop-

per.

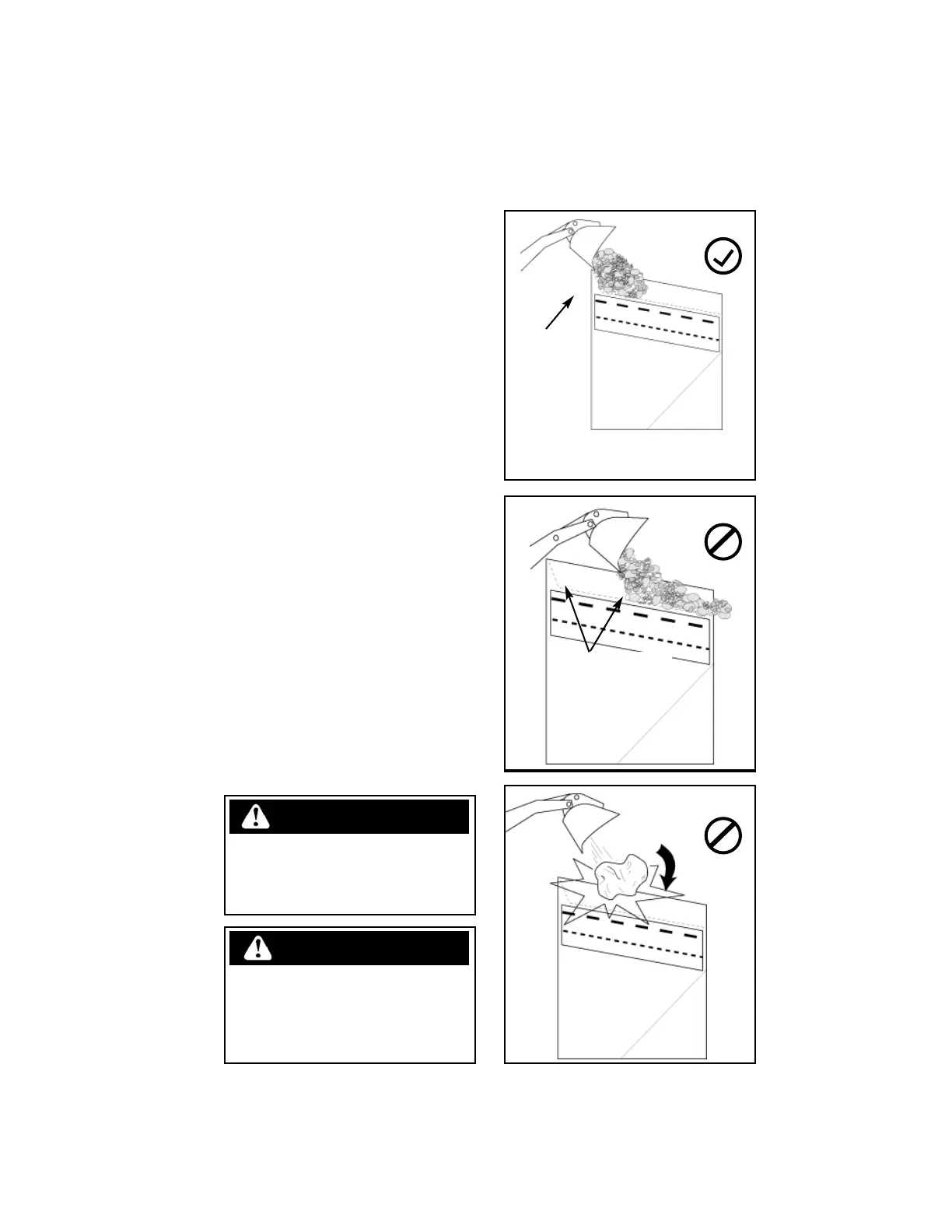

Dumping the material further down the

deck wastes processing area (fig. S0011).

This will allow good material to flow off

with the tailings.

Use extra care when placing large

heavy objects on the top screen deck. Make

sure smaller material is in front of the load

before lowering onto the top screen deck.

This will provide some cushion effect.

Never drop large heavy objects directly

onto the top screen deck (fig. S0012).

Immediate damage to the wire screen cloth

or shaker assembly may occur.

Keep an eye on tailings and finished

product. Do not allow to build up around

the shaker deck area. Retrieve product

before excessive build up around the shaker

area.

21

S0010

S0011

S0012

Hopper high

side

Wasted processing area

Large objects may roll uncontrollably off

the top screen deck. Ensure the area where

tailings are being discharged has adequate

run off area.

WARNING

Allowing excessive material to pile up

under the shaker deck may cause serious

damage to the machine.

CAUTION

Loading...

Loading...