4. MAINTENANCE

4.7 AS REQUIRED SERVICE

4.7B Tire and Wheel Maintenance

Inspect tires for cuts, cracks or uneven

wear. Check tire pressure and never over

inflate tires. Refer to the recommended

inflation pressure on the tire sidewall.

Wheels and studs should be checked for

cracks, deformation and proper and secure

attachment. Check wheel lug nut torques

for proper torque and visually inspect for

cracks or other damage.

Wheel Removal

Remove the lug nuts and remove both

the inner and outer wheels. Check wheels

and hubs for damage. Ensure that all studs,

lug nuts, and mounting faces of the hubs

and wheels are clean and free of grease and

debris.

Wheel Installation

• Mount both wheels over the hub boss-

es, being careful not to damage the stud

threads.

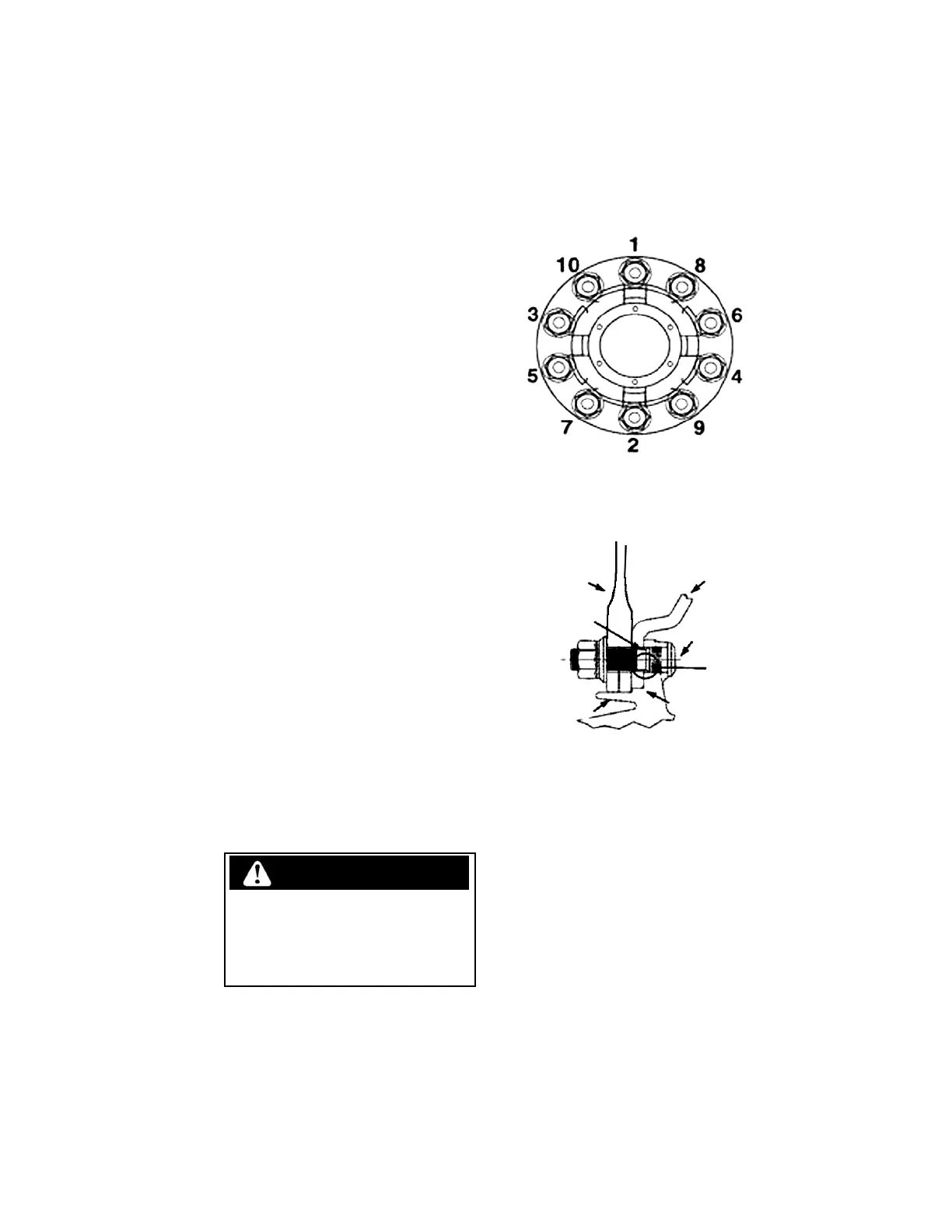

• Draw up the lug nuts alternately in the

sequence shown here. Do not tighten them

fully. This will allow uniform seating of

the lug nuts.

• Torque the lug nuts to 500-550 ft. lbs.

using this pattern.

51

Improper mounting torque can cause wheel

shimmy resulting in damage to the wheel

and axle parts. It may also cause discs to

crack in the stud hole area, extreme tire

wear, and stud breakage.

CAUTION

T90083

T90084

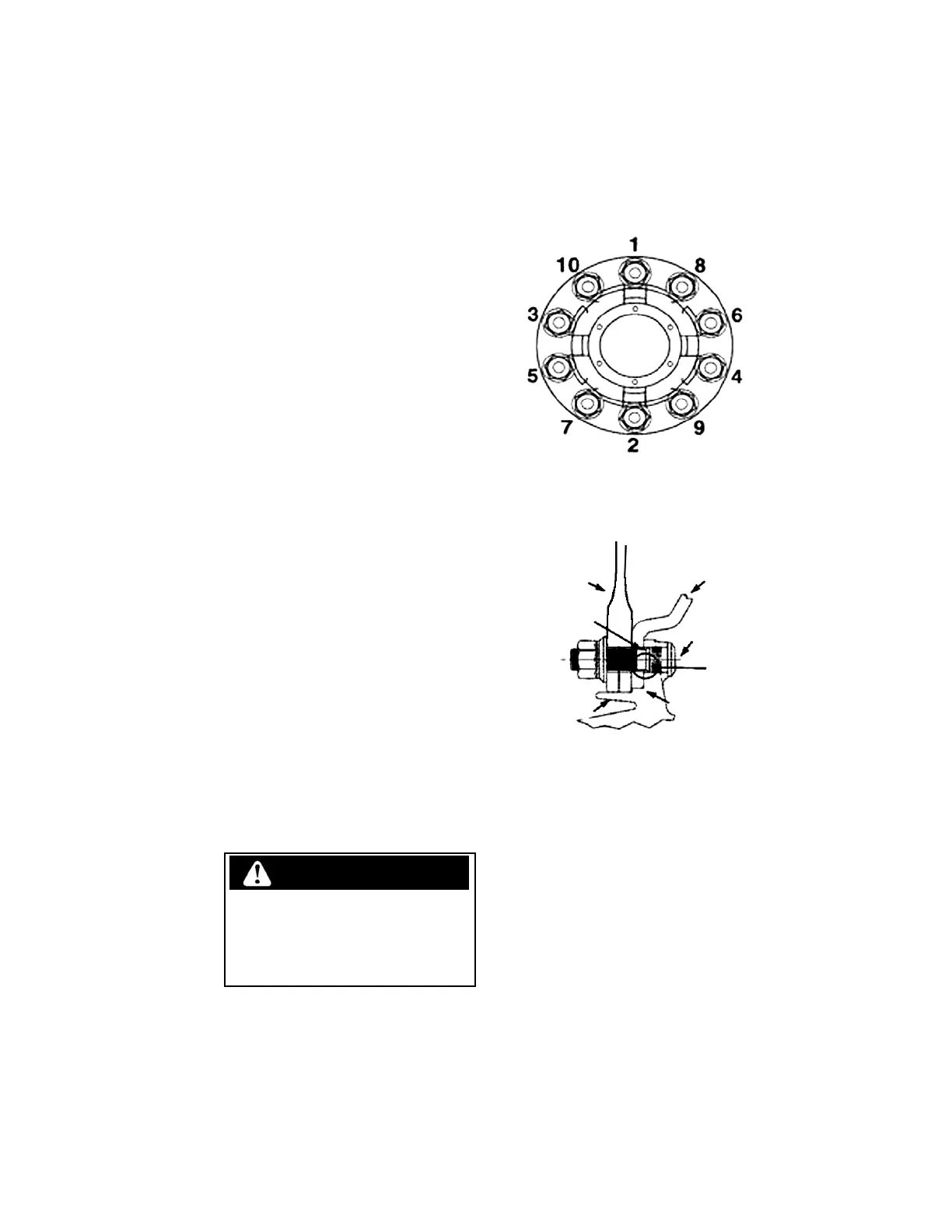

Clearance

22mm

Stud

Drum

15/16” (.94)

Dia. Bolt Hole

Disc Wheel

Disc Wheel Pilot

Drum Pilot

Pilot Mounted Disc

Loading...

Loading...