50

4. MAINTENANCE

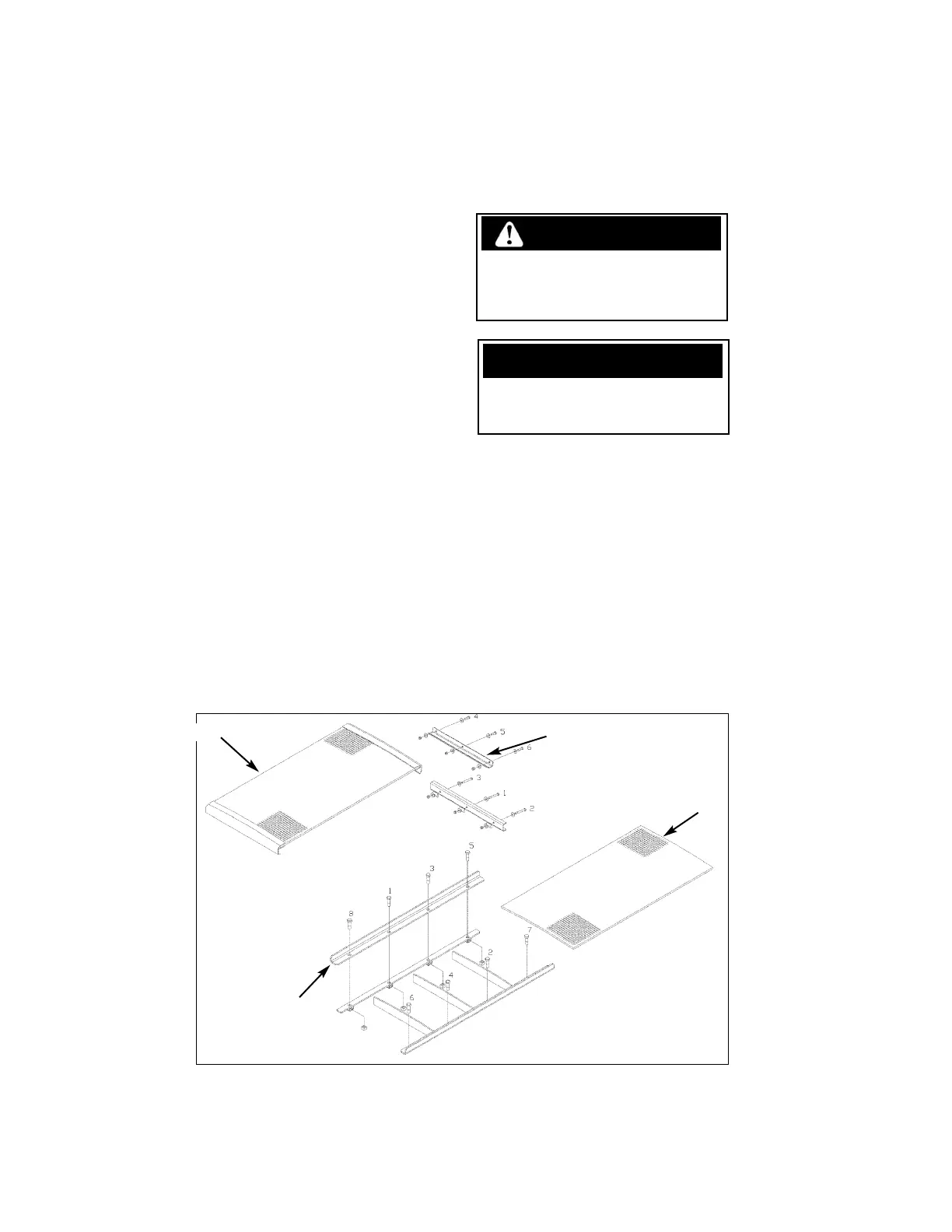

5. When replacing the screen or plate, fol-

low the torque tightening sequence

(T90034). Start from the middle, tighten

the bolts in a criss - cross pattern to

torque the top screen to 466 lbs. (632

Nm), and torque the lower screen to 120

lbs. ft (163 Nm) (T90034).

6 Ensure the screens are tight against the

crown bar rubbers. If necessary, tighten

the bolts further, in 25 lbs./ft. (34 Nm)

increments, until the screen is tight

against the crown bar rubbers.

7 Start the engine and engage the shaker

to verify. The screens must not bounce

freely on the crown bar rubbers. You

will notice if the screens are loose by

the rapping noise they will make. If

necessary, tighten the bolts further, in 25

lbs./ft. (34 Nm) increments, until the

screen is tight against the crown bar

rubbers.

Every 4 hours, torque the bolts retaining

the screens to the screen deck.

IMPORTANT

The shaker screens are very heavy.

Use a lifting aid such as a hoist to prevent

possible injury.

CAUTION

Screen bolt tightening sequence

T90034

Bottom Screen

Tension Bar

Tension Bar

Top Screen

Loading...

Loading...