OPERATING MANUAL 7. MAINTENANCE

ThyssenKrupp Aufzugswerke GmbH

7.6 Replacing of pulse generator

Disassembly:

• Remove cover at rear bearing bracket of machine.

• Remove connector plug on generator board (printed circuit board)

• Unscrew rotary support screw M3

• Unscrew locking screw on straining ring by means of hexagon socket

screw M2.5

• Grasp generator on bearing flange and carefully remove from shaft end

In the case of SA1 (2. generator) disassemble and remove 2. generator in

the same way.

Assembly:

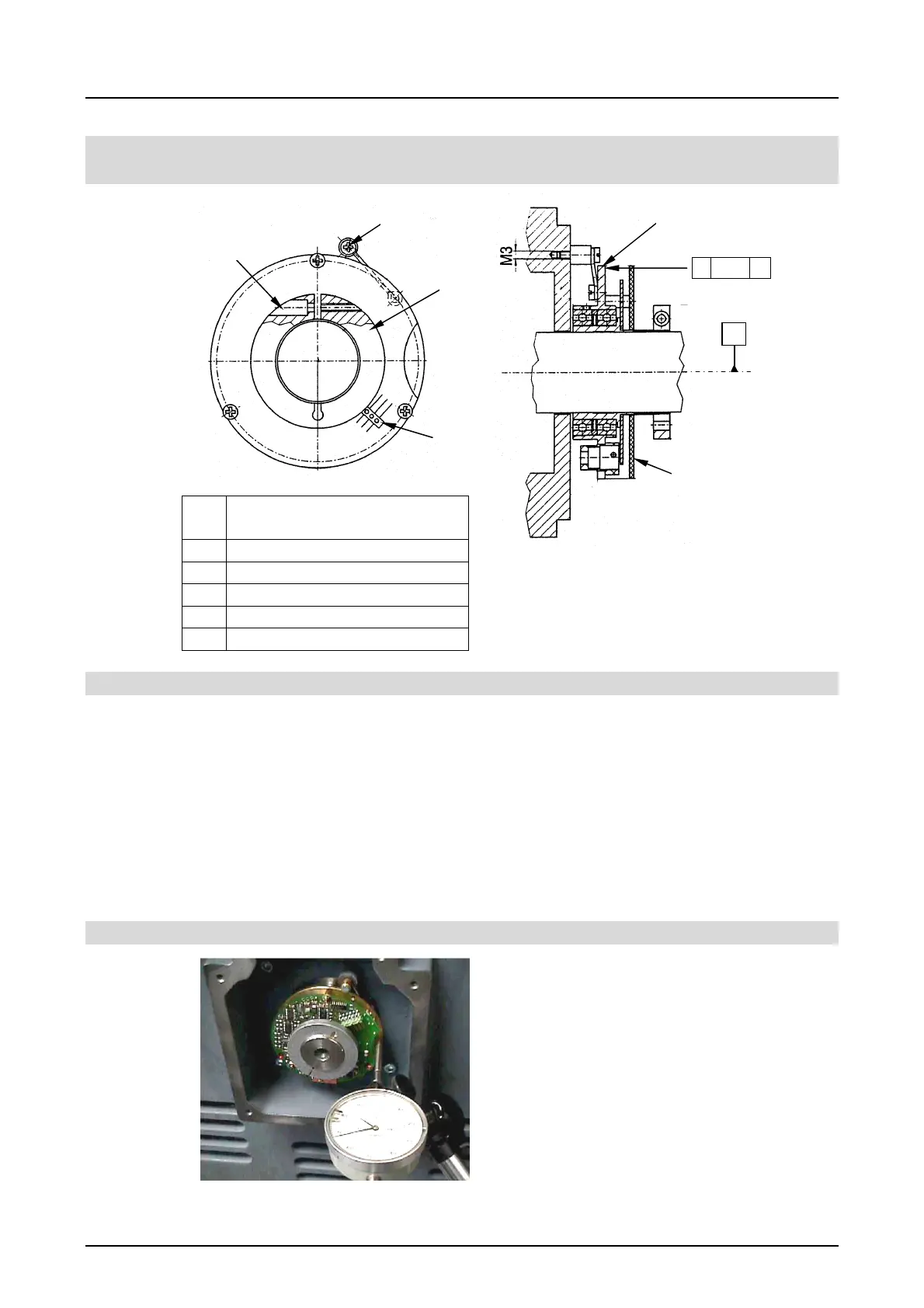

For mounting the generator a dial

gauge with indiator accurate to 0.01

mm incl. magnet holder is necessary.

• Clean but do not grease shaft prior to

mounting. Shaft end shall be clean

and not greasy.

• Check true running of shaft journal

and bearing flange by means of dial

gauge (max. radial run-out 0.03 mm)

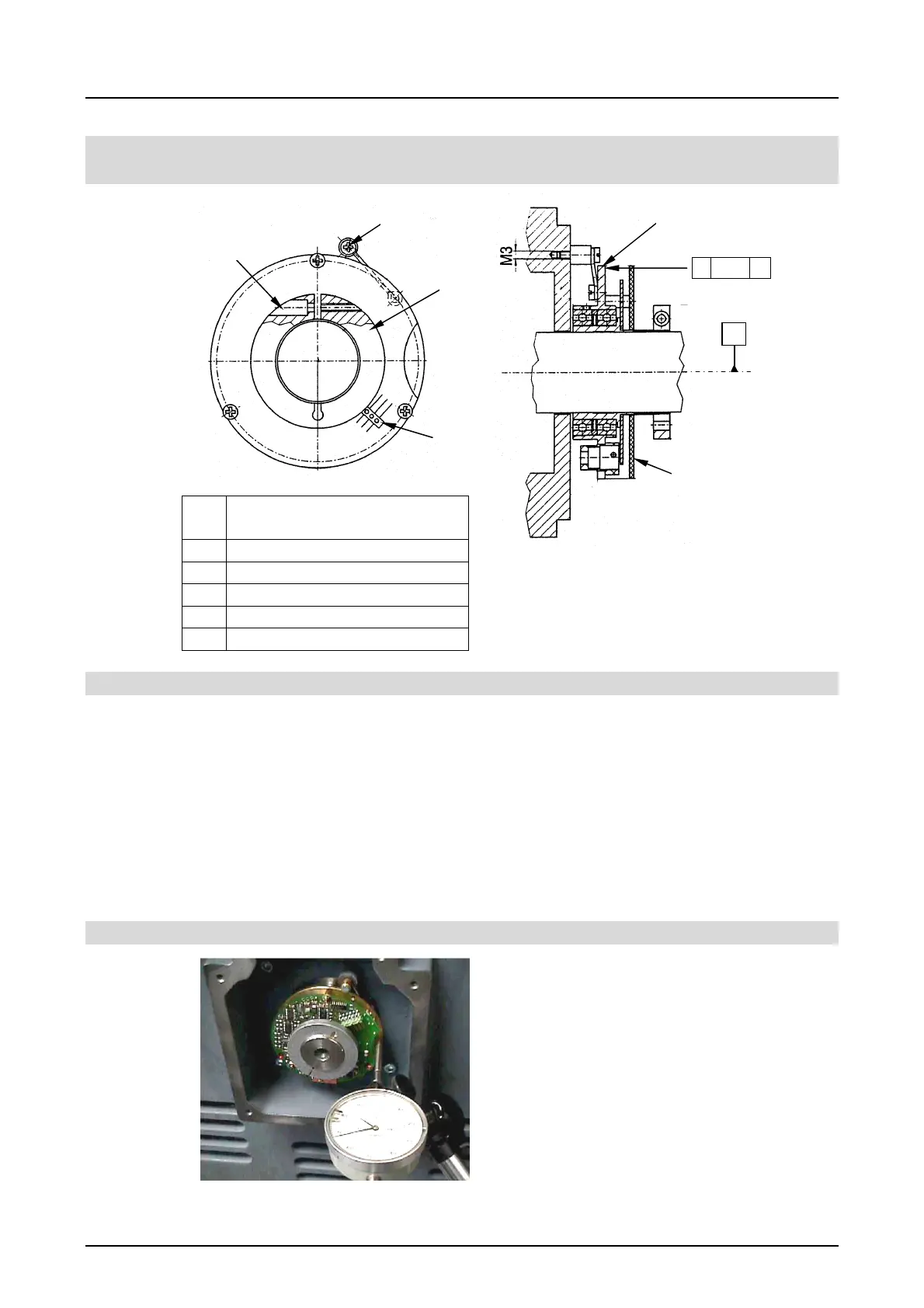

1

4

3

2

1 Drilled hole for locking

screw

2 Rotary support screw

3 Straining ring

4 Connection terminals

5 Bearing flange

6 Generator board

Fig. 16

Fig. 15

Technical data see 2.8

5

1

0.03

Loading...

Loading...