OPERATING MANUAL 1. SAFETY

ThyssenKrupp Aufzugswerke GmbH

1.3 Emergency operation ″

″″

″release after safety gear

operation″

″″

″

If safety gear operation is effected on car or counterweight side the traction of

the traction sheave may be insufficient for moving the car, the ropes may slip.

The following measures are necessary:

• Disconnect drive and control.

• Remove traction sheave cover and/or rope fixing beam above traction

sheave.

• Place hydraulic jack in location hole of machine frame on tension side of

lowered traction sheave.

• Bolt pressure arm with centering pin down to end face of traction sheave.

Use thread close to jack (see fig. 2)

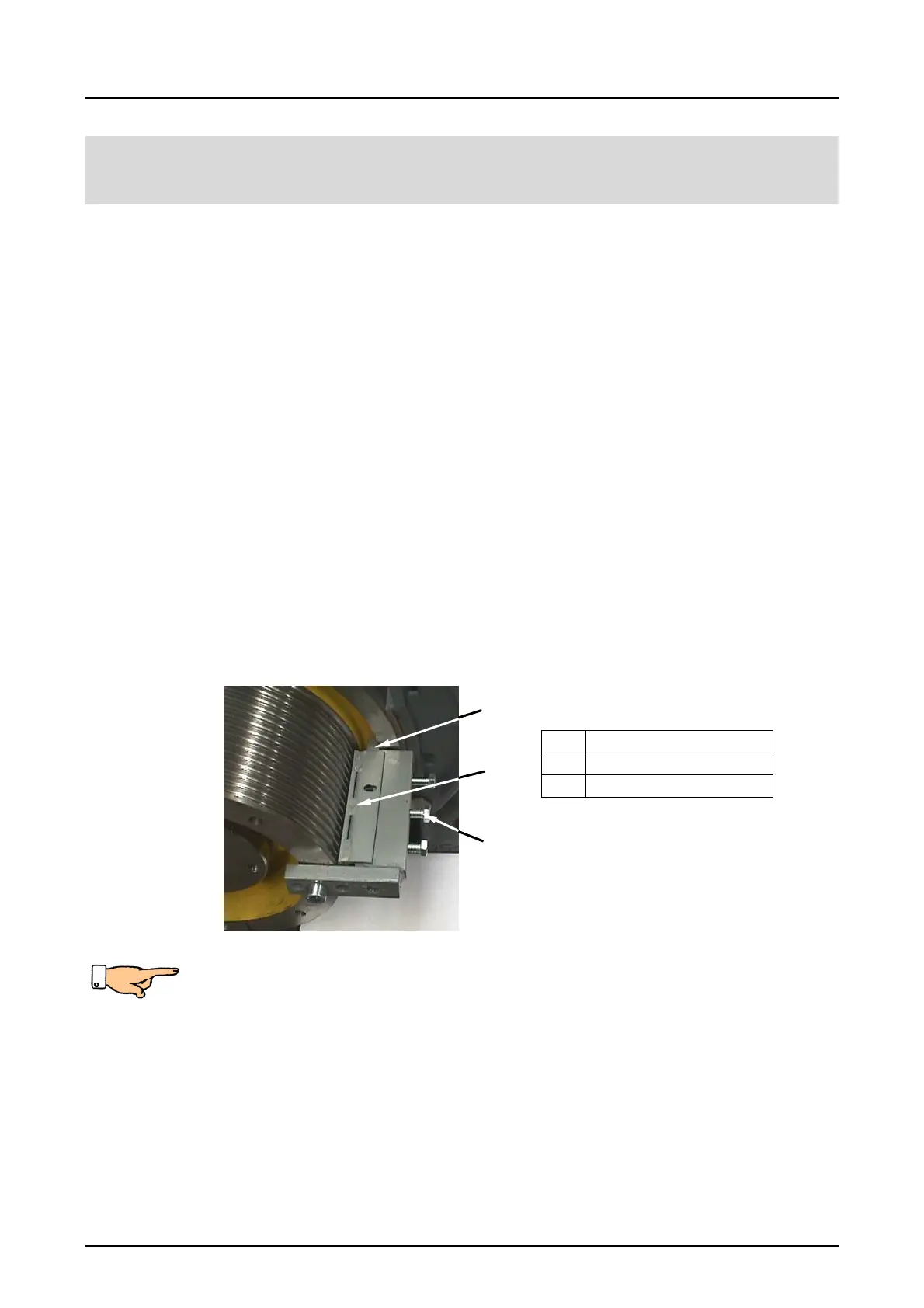

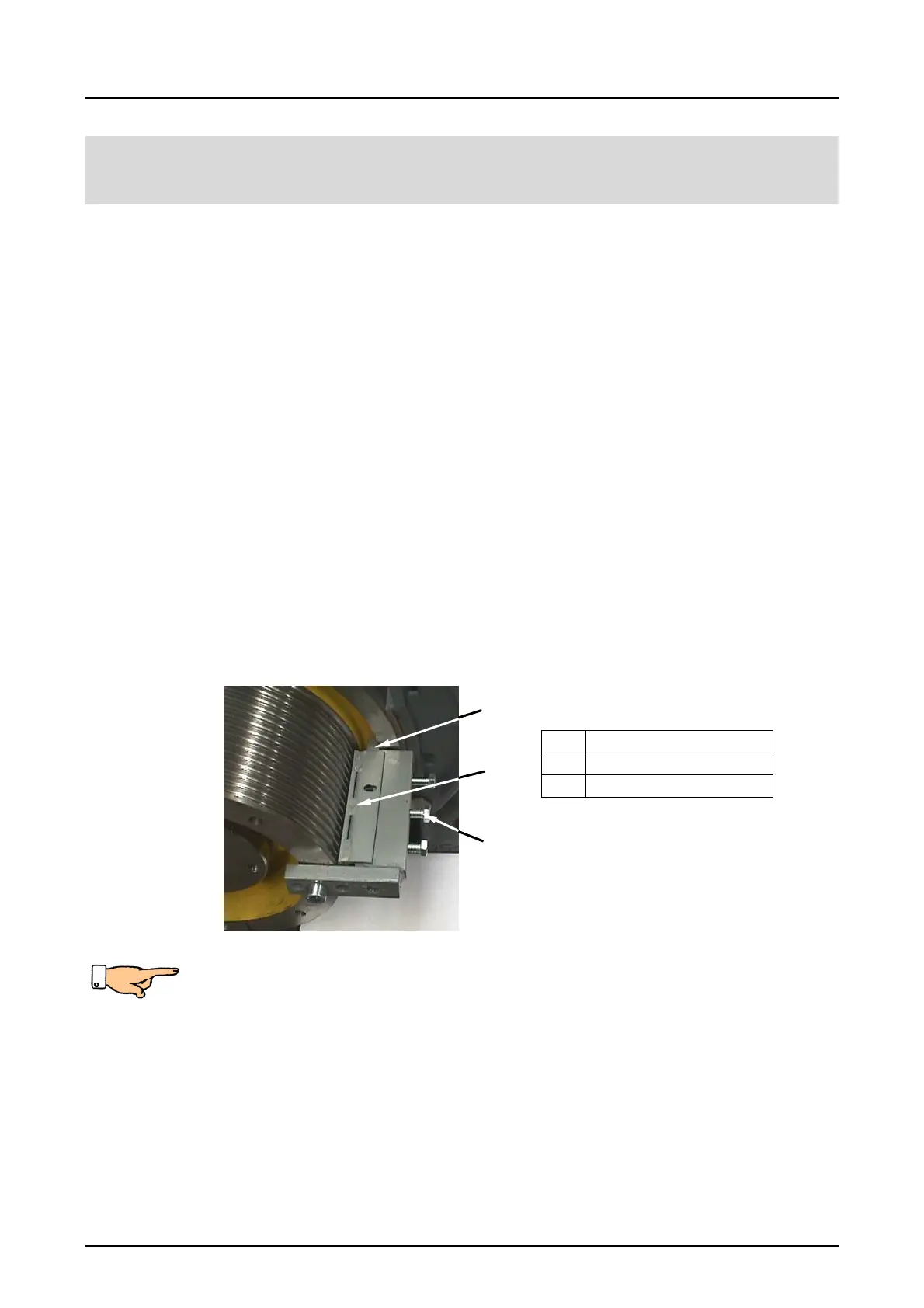

• Nest nib of blocking clamp in snap ring groove below the brake disk and

screw to traction sheave in next thread above thrust piece (see fig. 1).

• Tighten 3 pressure screws and clamp ropes by means of thrust piece.

• Operate brake release lever on brake magnet and move traction sheave

into desired direction until the grip wedge is released by pushing the lever

upwards and downwards. (See to it that the drain valve is closed and the

centering pin of the thrust piece shall rest on the groove of the lever).

• Remove the blocking clamp and install the rope fixing bracket in

accordance with the instructions after disengagement.

Installation of blocking clamp

Note: if the travel of the hydraulic jack or the travel of the traction sheave is

not enough for releasing the car, it shall be maintained in its position with the

rope clamp. The recess of the rope clamp shall rest on the machine frame

and the other rope clamp side on the welded-on bracket on the inside of the

frame.

Lower hydraulic jack, re-adjust thrust piece on next fastening thread on

traction sheave above hydraulic jack. Re-adjust blocking clamp if the travel is

insufficient.

Fig. 1

1

Nib

2 Thrust piece

3 Pressure screw

1

2

3

Loading...

Loading...