MEP S.p.A.

5--6

31

Use and maintenance manual TIGER 370 CNC--MR

Lubricant/coolant fluid supply

It is possible to select the operating mode of the coolant by means of the specific

buttons on the control panel:

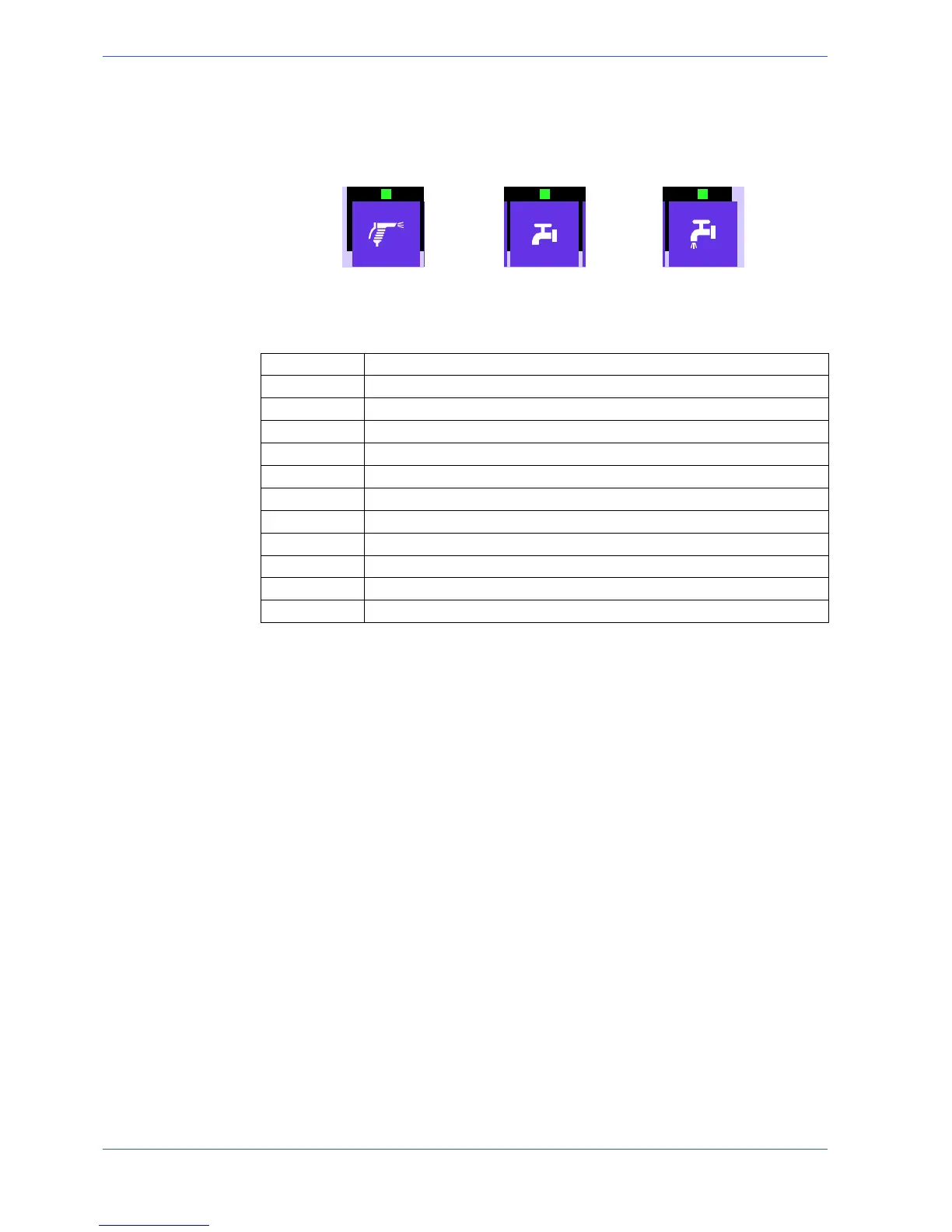

Technological control parameters

The following table indicates the control parameters which are shown on the

displays of the semi---automatic, automatic and Automatic Loop operating cycles.

X =1000,5

X---axis dimension (position of feeder carriage)

θ =00,00

Nonoperati ng

W =000.0

Nonoperati ng

F=0

Cutting head descent speed potentiometer

S=15

Disc rot ation speed (rpm)

Kg=000

Nonoperati ng

DL=0

Nonoperati ng

SL= 3

Blade thickness (depends upon machine model)

AM=5,8

Max. blade motor absorption

A =0,7

Amperometer

T =00,00

Partial cutting time

TT=00,00

Total machine time for the cutt ing cycle

Preliminary check list for cutting operation

To guarantee complete safety dur ing cutting cycles, the operator should work

through a check list of the entire apparatus, checking:

" ensure that the disk guard completely surrounds the tool when it is not in use;

" that the work piece is properly clamped in place;

" ensure that the blade teeth are appropriate for the material being cut;

" that the speed selected is right for the kind of piece to be cut;

" that all protections are in place and correctly locked;

" lubricant/coolant level and activation of the electropump;

" the blade downstroke speed must be correct.

Loading...

Loading...