Left and Right Chambers – can be set to any

temperature at or between 50° – 75°C

(122°–167°F); each chamber can be used for one

of the following at any one time (preference

depends on your chosen work flow direction):

Q

warming area for various sized base molds (close

lid to keep heat in and dust out)

OR

Q

paraffin bath to keep processed tissue specimens at

the appropriate temperature (close lid to keep heat

in, and dust out, when embedding process is fin-

ished or temporarily stopped).

Transfer Tray – may be used to transfer

processed specimens to the Embedding Module

or may be half-filled with paraffin and then used

as a paraffin bath.

Waste Drawers – catch molten paraffin that drains

through two holes in grooves around hot plate

area.

Cold Spot – cools liquid paraffin at the bottom

of a base mold so tissue can be correctly posi-

tioned.

Hot Plate – ensures that paraffin does not solidi-

fy during embedding process; can be set to any

temperature at or between 50°– 75°C

(122°–167°F); factory set at 62°C (143°F). This

temperature setting is also used for the Forceps

Warmer Holders.

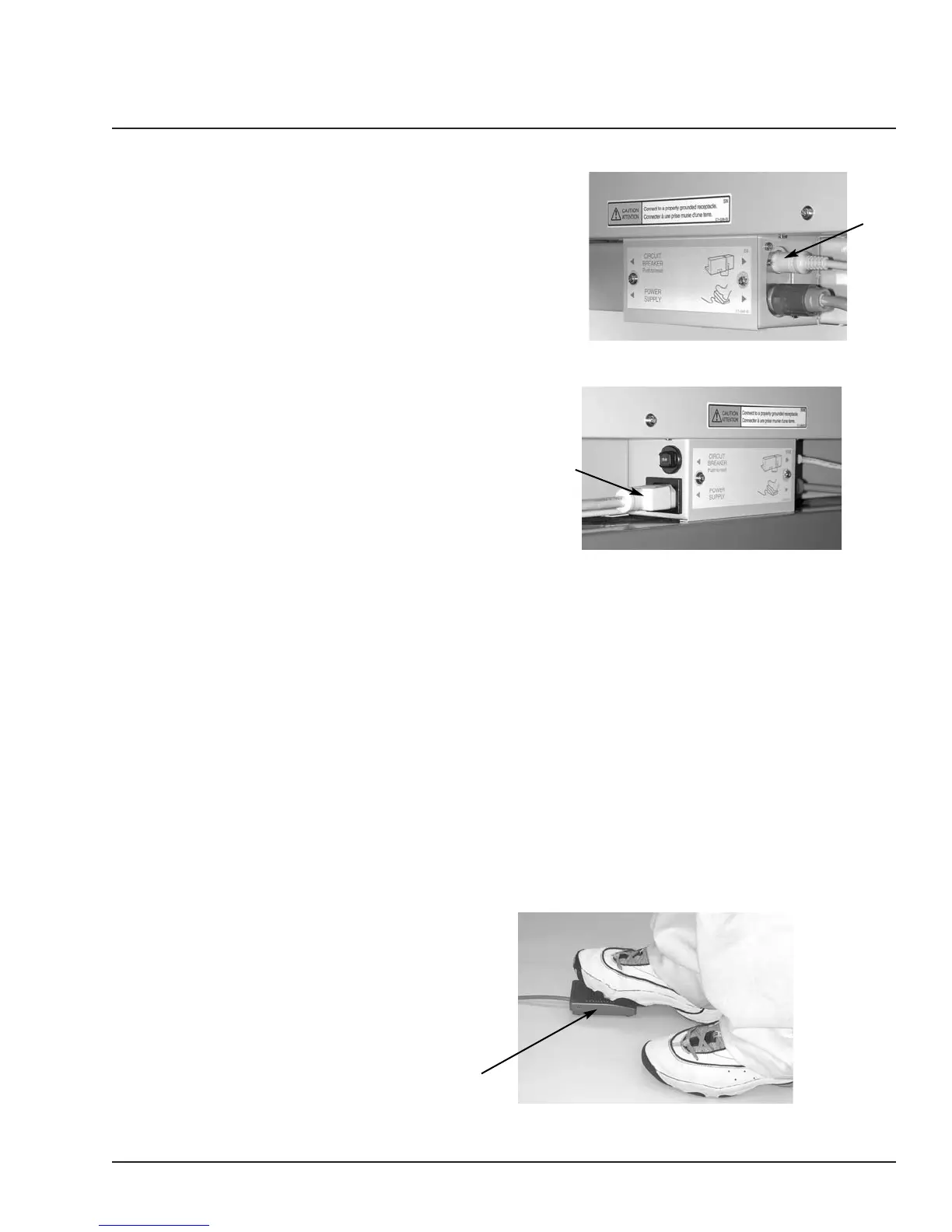

(Optional) Foot Pedal – for hands-free paraffin

dispensing.

Display Adjustment Wheel – controls the con-

trast for the display.

Embedding Module

(BACK PANEL)

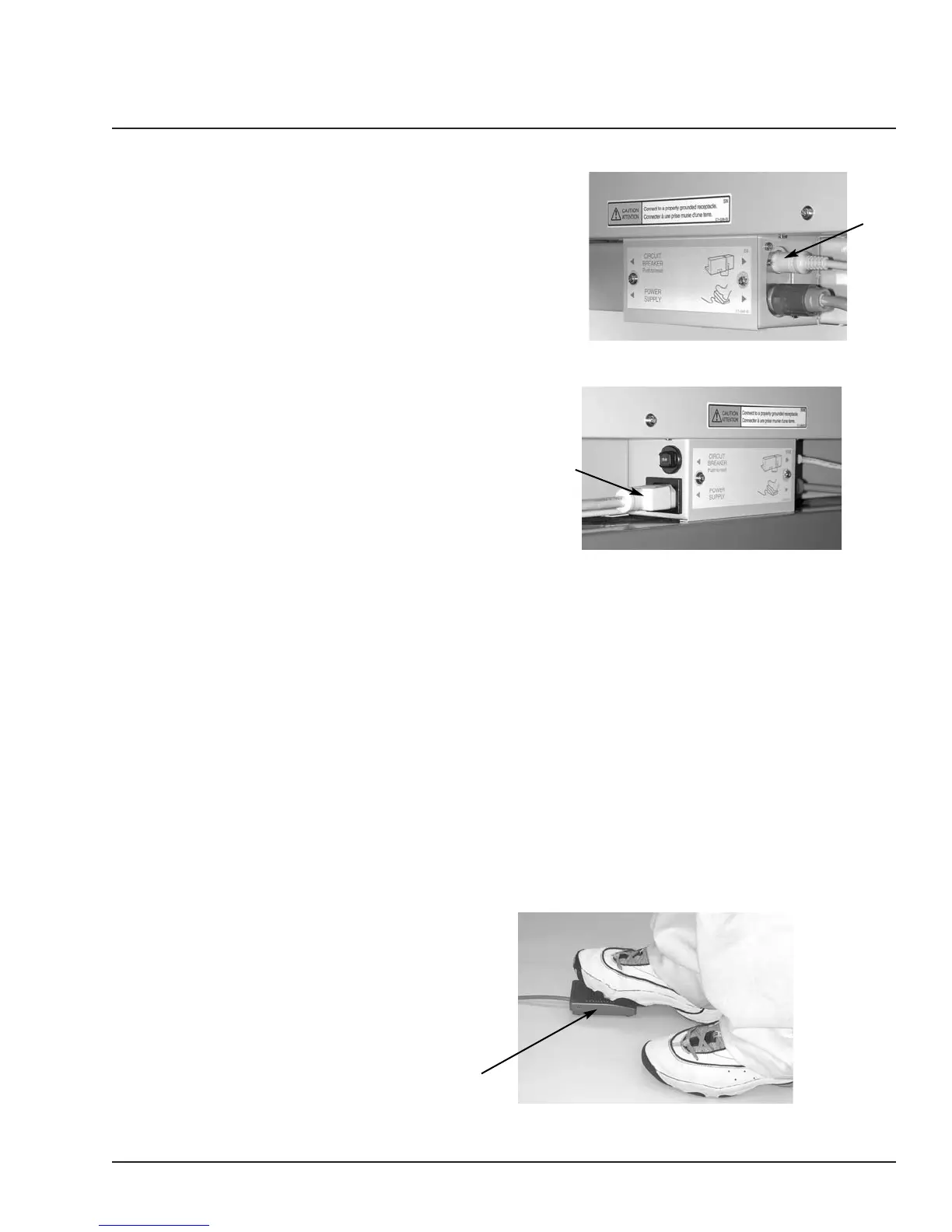

Cryo Module Connector – accepts the plug to

the Cryo Module. The Cryo Module operation is

controlled by the Embedding Module.

Power Cord Connector – accepts the plug for

connecting the power cord to the module.

Revised 07/12/11 2.3

Loading...

Loading...