INSPECTION AND MAINTENANCE72

10

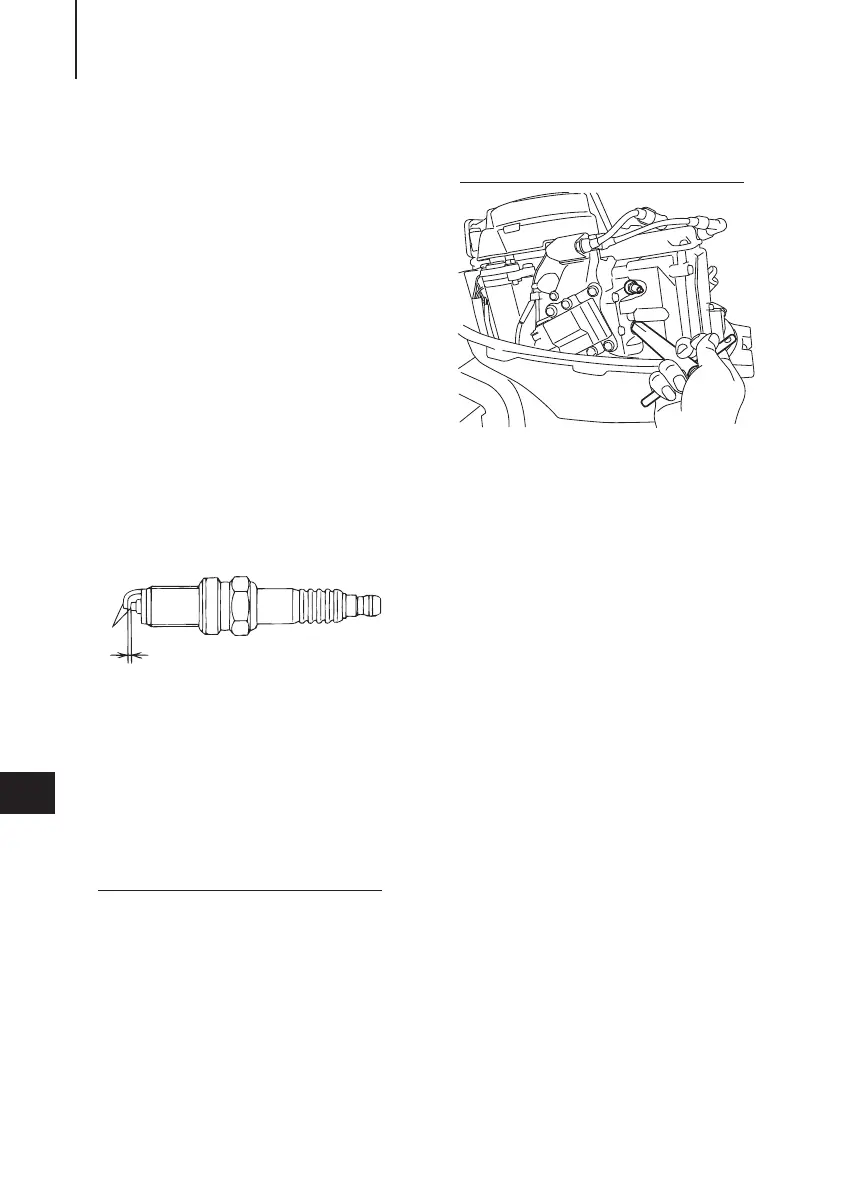

2. Remove the top cowl.

3. Remove the spark plug caps.

4. Remove the spark plugs by turning it

counter-clockwise, using a 5/8" (16

mm) socket wrench and handle that is

provided in tool bag.

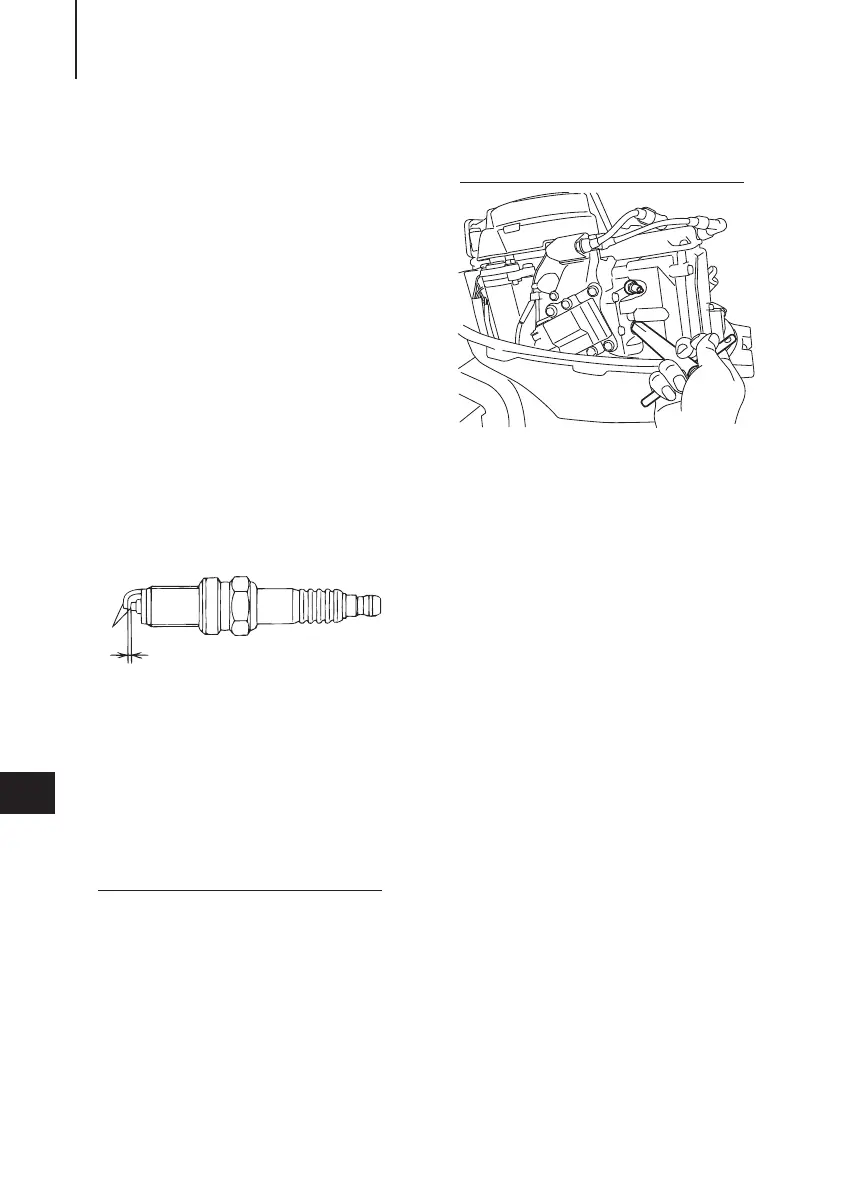

5. Inspect the spark plug. Replace the

spark plug if the electrodes are worn or

if the insulators are cracked or

chipped.

6. Measure the spark plug electrode gap

with a wire type feeler gauge. The gap

should be 0.8-0.9 mm (0.031-0.035

inches). If the gap is different, replace

the spark plug with a new one

Use spark plug NGK DCPR-6E.

1. Electrode

2. Spark gap (0.8–0.9 mm, 0.031–0.035 in)

7. Install the spark plug by hand and turn

it carefully to avoid cross-threading.

8. Tighten the spark plug to the specified

torque.

ENON00028-0

Note

z Spark plug torque:

18.0 Nm (13.3 ft-lb) [1.84 kgf-m]

If a torque-wrench is not available when you

are fitting a spark plug, a good estimate of

the correct torque is 1/4 to 1/2 a turn past

finger-tight. Have the spark plug adjusted to

the correct torque as soon as possible with

a torque-wrench.

1

2

ENOF00085-0

ENOF01427-0

0)6$B(85B(1B1ERRN࣮࣌ࢪ㸰㸮㸯㸲ᖺ㸯㸰᭶㸯㸱᪥ࠉᅵ᭙᪥ࠉ༗ᚋ㸳㸲㸷ศ

Loading...

Loading...