− 13 −

R-CL300-0-1204-02

2-4 Measurement Principle

CL-300 has employed the imaging system different from that in CL-2500 or the manual lens meter LM. It

enables the non-imaging system by using the two-dimensional CCD.

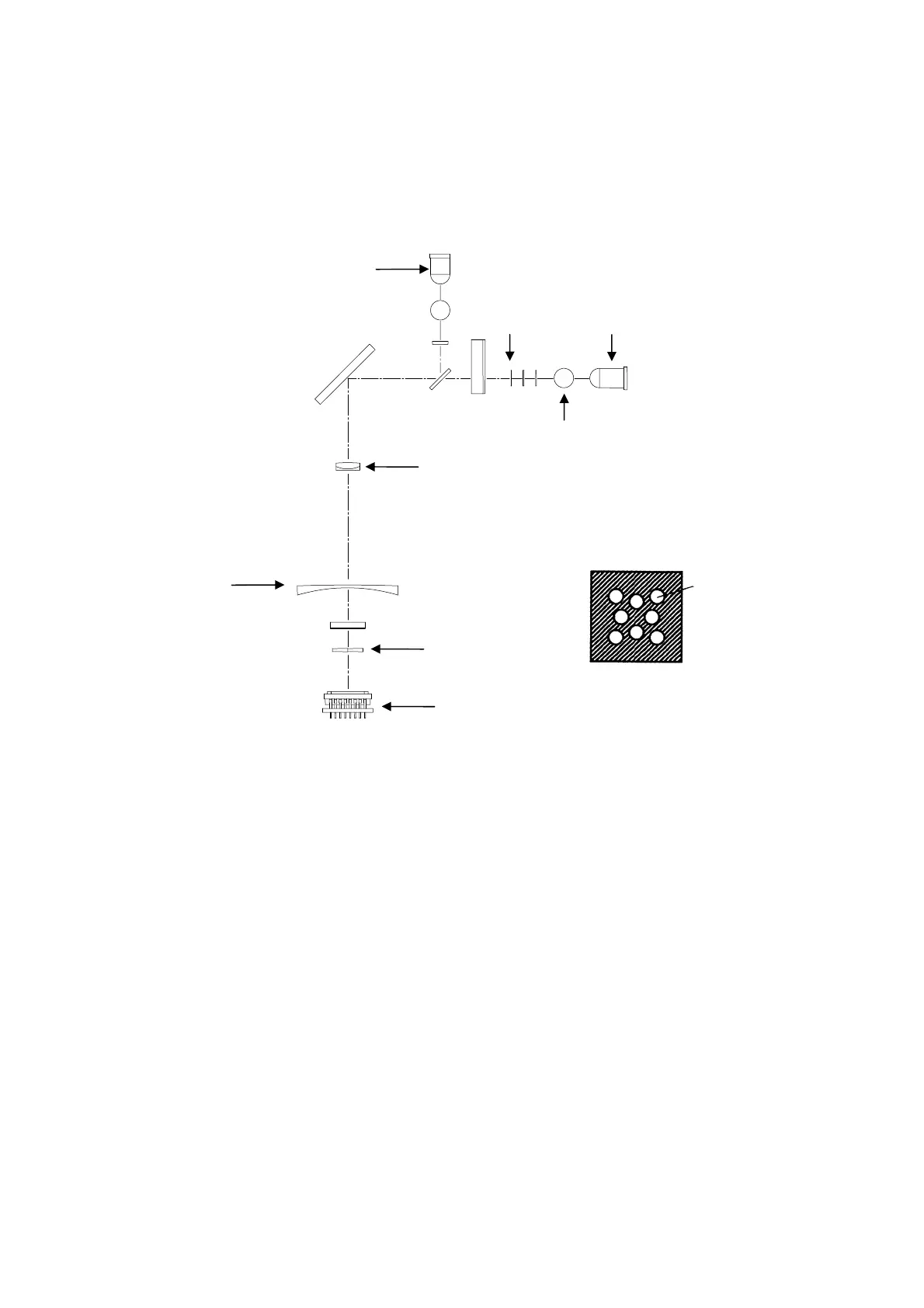

The measurement principle is described based on the following optical arrangement sketch drawing.

The light emitted from the LED is changed into the spot light using the ball lens and then, it is changed into

parallel rays using the collimator lens. These rays are sent into the lens to be tested.

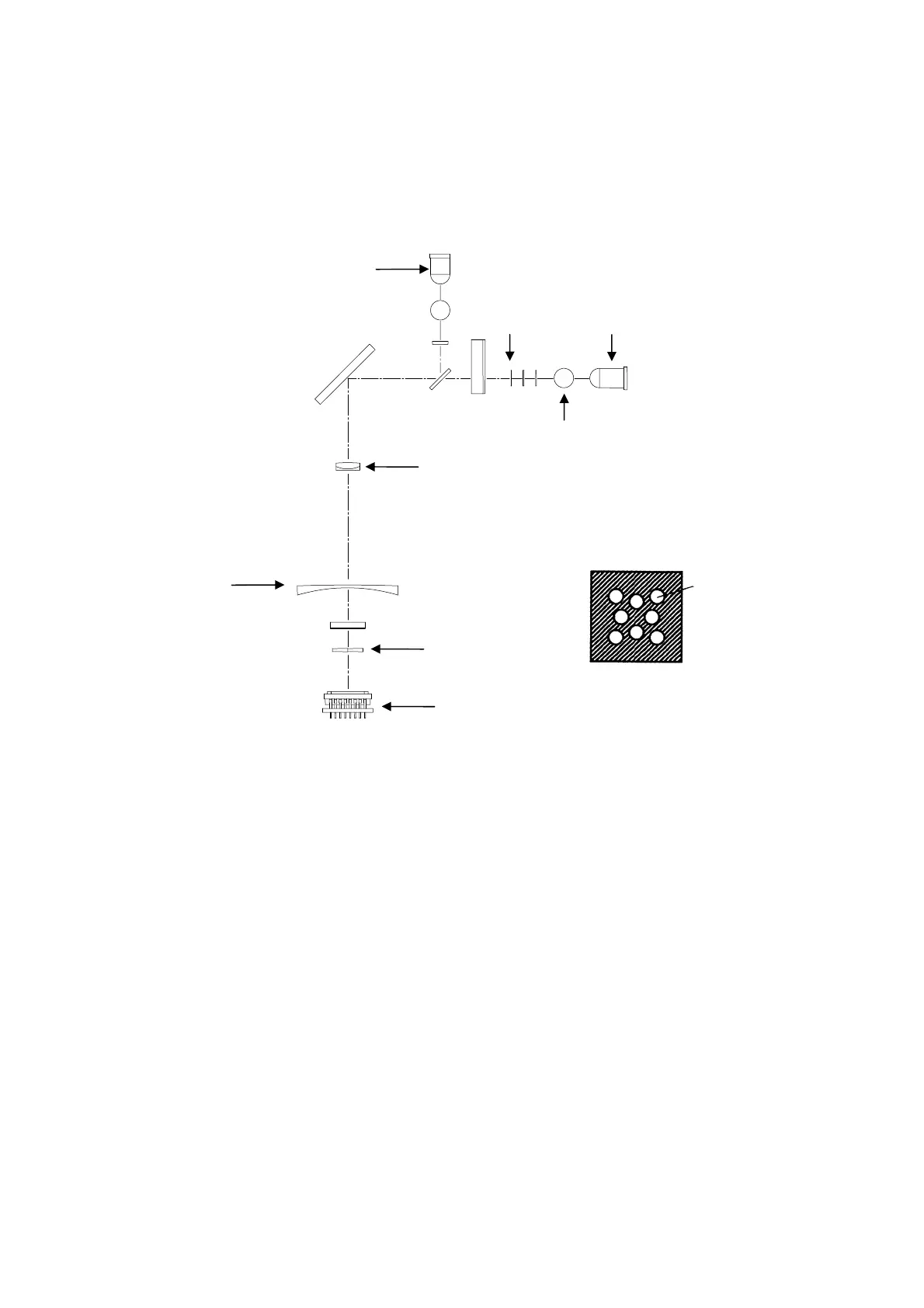

After going through the lens to be tested, the light is changed into 8-spot images using the target with the

eight circular openings and is projected on the surface of the two-dimensional CCD.

In the case that the lens to be tested has not been inserted (Fig 1), the light as parallel rays goes through the

openings on the target, and so the interval between the openings on the target is approximately equal to that

between the images created on the CCD. At that time, the positions of the images created on the CCD are

used as the reference positions.

On the contrary, when the lens to be tested with positive power, is inserted (Fig. 2), the interval between the

images on the CCD is smaller than that of the openings on the target.

In the case that the lens with cylindricality is inserted, the interval between the eight point images created on

the CCD is changed. This direction is regarded as the axial angle.

The light emitted from the UVLED is changed into the spot light using the ball lens and then, it is changed

into parallel rays using the collimator lens. These rays are sent into the lens to be tested.

After going through the lens to be tested, the light is projected on the two-dimensional CCD and is converted

into electricity. The light accumulated in the given time is calculated as the integral time.

The status without lens is regarded as “100%”. By comparing with the status with lens, transmittance is

calculated.

Diaphragm

Collimator Lens

Target

LED

Ball Lens

Lens to be tested

Two-dimensional CCD

Target

Opening

UVLED

Loading...

Loading...