Checkingthe

Hydraulic-FluidLevel

ServiceInterval:Beforeeachuseordaily

Thereservoirislledatthefactorywith56.7L(15US

gallons)ofhigh-qualityhydraulicuid.Thebesttime

tocheckthehydraulicoiliswhentheuidiscold.The

machineshouldbeinitstransportconguration.The

recommendedreplacementuidis:

ToroPremiumAllSeasonHydraulicFluid(Availablein

19L(5USgallon)pailsor208L(55USgallon)drums.See

thePartsCatalogoryourToroDistributorforpartnumbers.)

Alternativeuids:IftheT orouidisnotavailable,

otherconventional,petroleum-baseduidsmaybe

used,providedthattheymeetallofthefollowing

materialpropertiesandindustryspecications.Check

withyouroilsuppliertoseewhethertheoilmeets

thesespecications.

Note:T orodoesnotassumeresponsibilityfor

damagecausedbyimpropersubstitutions,souse

onlyproductsfromreputablemanufacturerswho

standbehindtheirrecommendation.

HighViscosityIndex/LowPourPointAntiwearHydraulic

Fluid,ISOVG46Multigrade

MaterialProperties:

Viscosity,ASTMD445cSt@40°C(104°F)

44to48

cSt@100°C(212°F)

7.9to9.1

Viscosityindex,ASTM

D2270

140orhigher(high

viscosityindexindicatesa

multiweightuid)

Pourpoint,ASTMD97-36.7°Cto-45°C(-34°Fto

-49°F)

FZG,failstage

11orbetter

Watercontent(newuid)500ppm(maximum)

IndustrySpecications:

VickersI-286-S,VickersM-2950-S,DenisonHF-0,

Vickers35VQ25(EatonATS373-C)

Theproperhydraulicuidsmustbespeciedfor

mobilemachinery(asopposedtoindustrialplant

usage),multiweight-type,withZnDTPorZDDP

anti-wearadditivepackage(notanashless-typeuid).

Important:Manyhydraulicuidsarealmost

colorless,makingitdifculttospotleaks.A

reddyeadditiveforthehydraulicsystemoilis

availablein20ml(2/3oz)bottles.1bottleis

sufcientfor15to22L(4to6USgallons)of

hydraulicoil.OrderPartNumber44-2500from

yourToroDistributor.

Synthetic,BiodegradableHydraulicFluid(Availablein

19L(5USgallon)pailsor208L(55USgallon)drums.See

thePartsCatalogoryourToroDistributorforpartnumbers.)

Thishigh-quality,synthetic,biodegradableuidhas

beentestedandfoundcompatibleforthisT oro

model.Otherbrandsofsyntheticuidmayhave

sealcompatibilityproblemsandTorocannotassume

responsibilityforunauthorizedsubstitutions.

Note:Thissyntheticuidisnotcompatiblewiththe

ToroBiodegradableFluidpreviouslysold.Seeyour

ToroDistributorformoreinformation.

1.Positionthemachineonalevelsurface,lower

thecuttingunits,andstoptheengine.

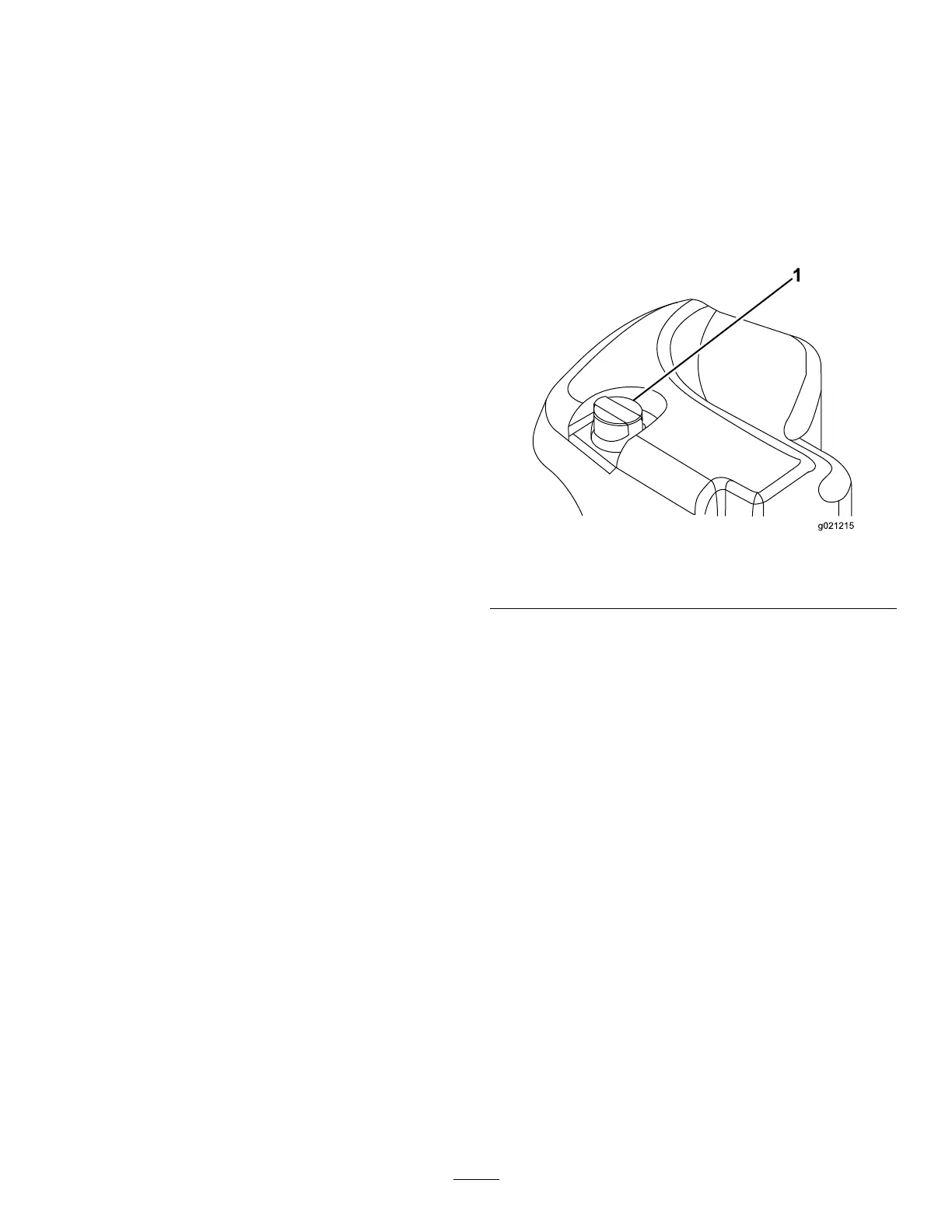

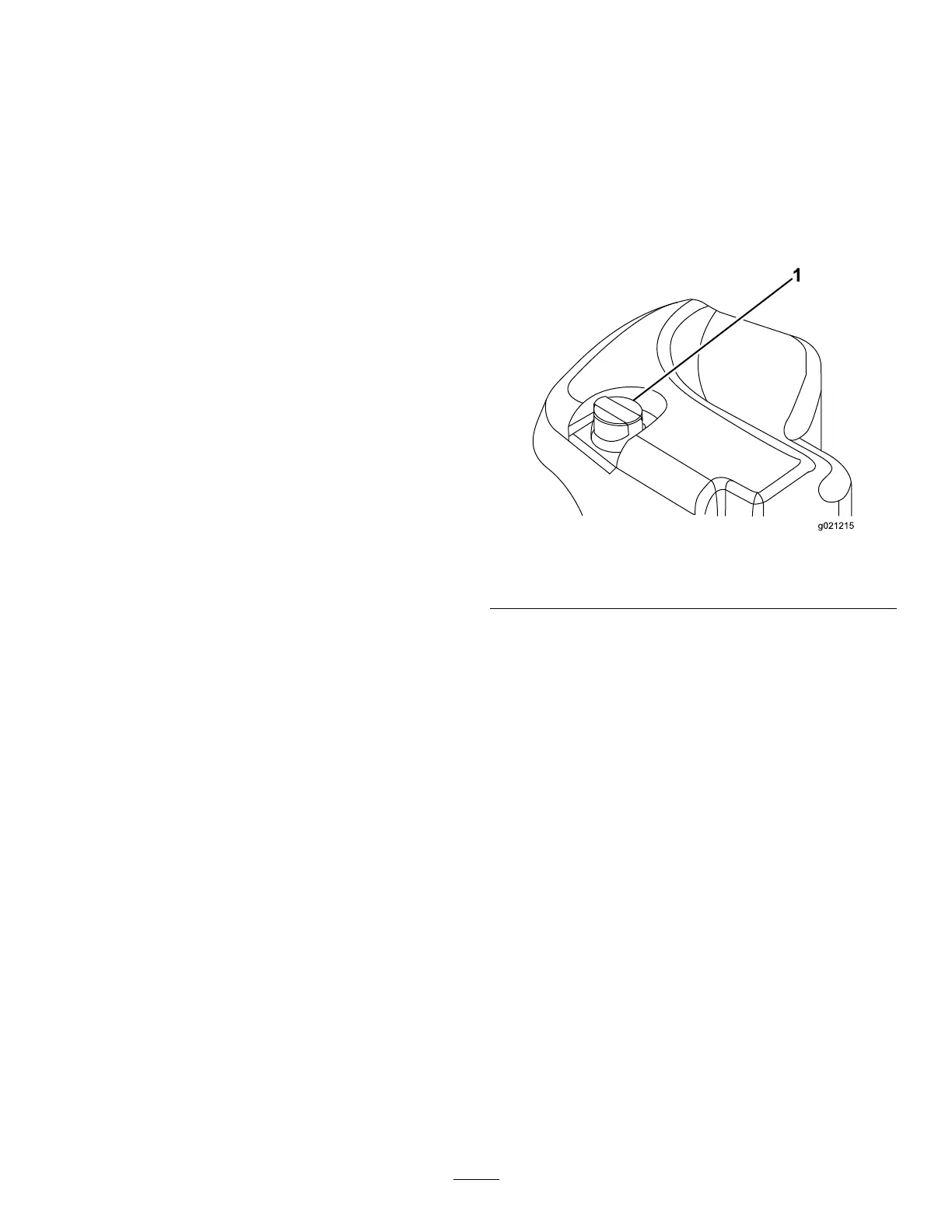

2.Cleantheareaaroundthellerneckandthe

capofthehydraulictank(Figure64).

g021215

Figure64

1.Hydraulic-tankcap

3.Removethecap/dipstickfromthellerneckand

wipeitwithacleanrag.

4.Insertthedipstickintothellerneck;then

removeitandcheckthelevelofuid.

Note:Theuidlevelshouldbewithinoperating

rangeonthedipstick.

Important:Donotoverllthetank.

5.Ifthelevelislow,addtheappropriateamountof

uidtoraisetheleveltothefullmark.

6.Installthecap/dipstickontothellerneck.

ChangingtheHydraulic

Fluid

ServiceInterval:Every800hours

Every2years—Drainandushthehydraulic

tank.

Iftheuidbecomescontaminated,contactyourT oro

Distributorbecausethesystemmustbeushed.

Contaminateduidlooksmilkyorblackwhen

comparedtocleanoil.

1.Stoptheengineandraisethehood.

48

Loading...

Loading...