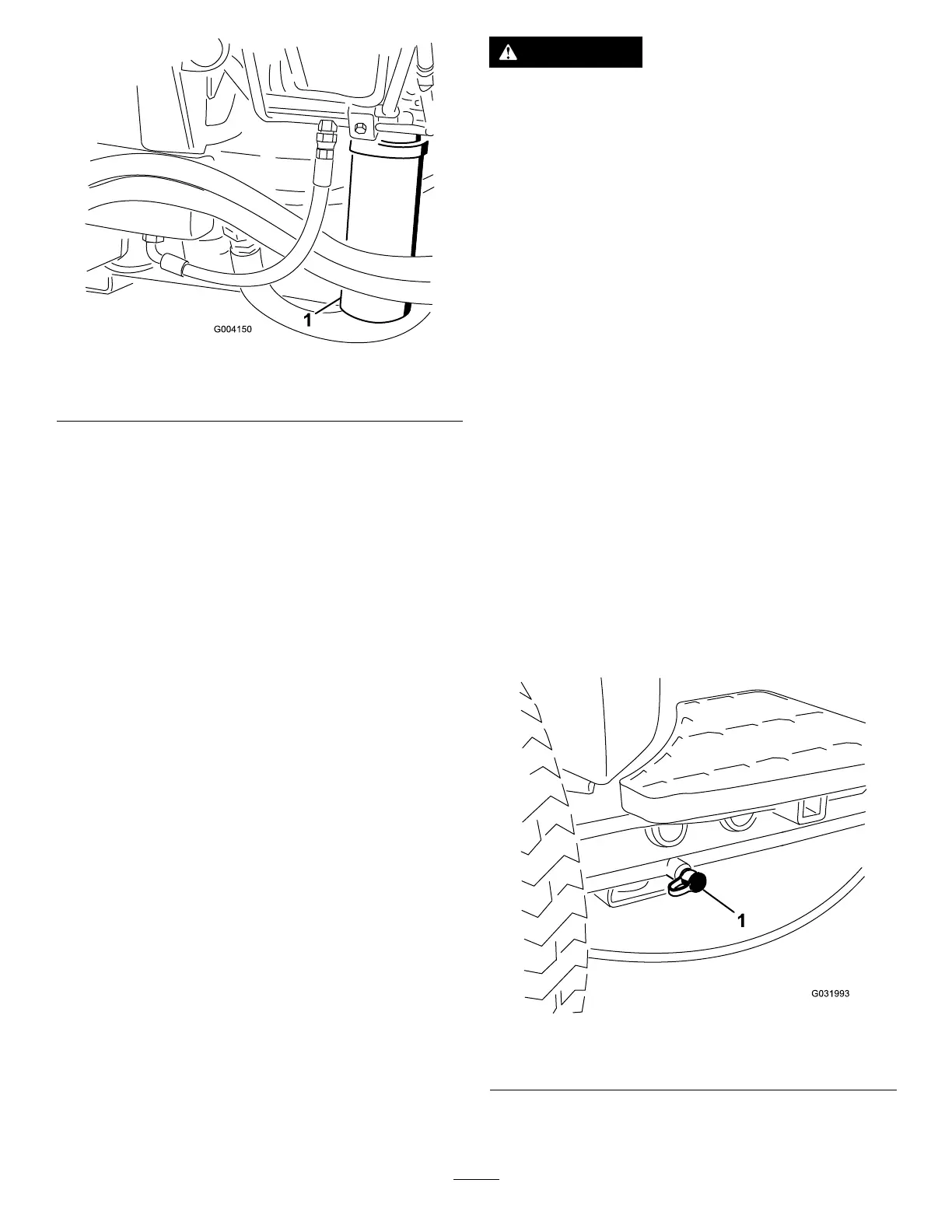

g004150

Figure68

1.Hydrauliclter

3.Removethelter.

4.Lubricatethegasketonthenewlterwith

hydraulicoil.

5.Ensurethattheltermountingareaisclean.

6.Installthelterbyhanduntilthegasketcontacts

themountingsurface,thenrotateitanadditional

1/2turn.

7.Repeattheprocedureontheotherlter.

8.Starttheengineandletitrunforabout2minutes

topurgeairfromthesystem.

9.Stoptheengineandcheckforleaks.

CheckingtheHydraulic

LinesandHoses

ServiceInterval:Beforeeachuseordaily

Checkhydrauliclinesandhosesforleaks,kinked

lines,loosemountingsupports,wear,loosettings,

weatherdeterioration,andchemicaldeterioration.

Makeallnecessaryrepairsbeforeoperating.

WARNING

Hydraulicuidescapingunderpressurecan

penetrateskinandcauseinjury.

•Makesurethatallhydraulic-uidhoses

andlinesareingoodconditionandall

hydraulicconnectionsandttingsaretight

beforeapplyingpressuretothehydraulic

system.

•Keepyourbodyandhandsawayfrom

pinholeleaksornozzlesthateject

high-pressurehydraulicuid.

•Usecardboardorpapertondhydraulic

leaks.

•Safelyrelieveallpressureinthehydraulic

systembeforeperforminganyworkonthe

hydraulicsystem.

•Getimmediatemedicalhelpifuidis

injectedintoskin.

TestingthePressureinthe

HydraulicCircuits

Usethehydraulicsystemtestportstotestthe

pressureinthehydrauliccircuits.ContactyourToro

Distributorforassistance.

Usethetestportsonthefronthydraulictubes(Figure

69)toassistintroubleshootingthetractioncircuit.

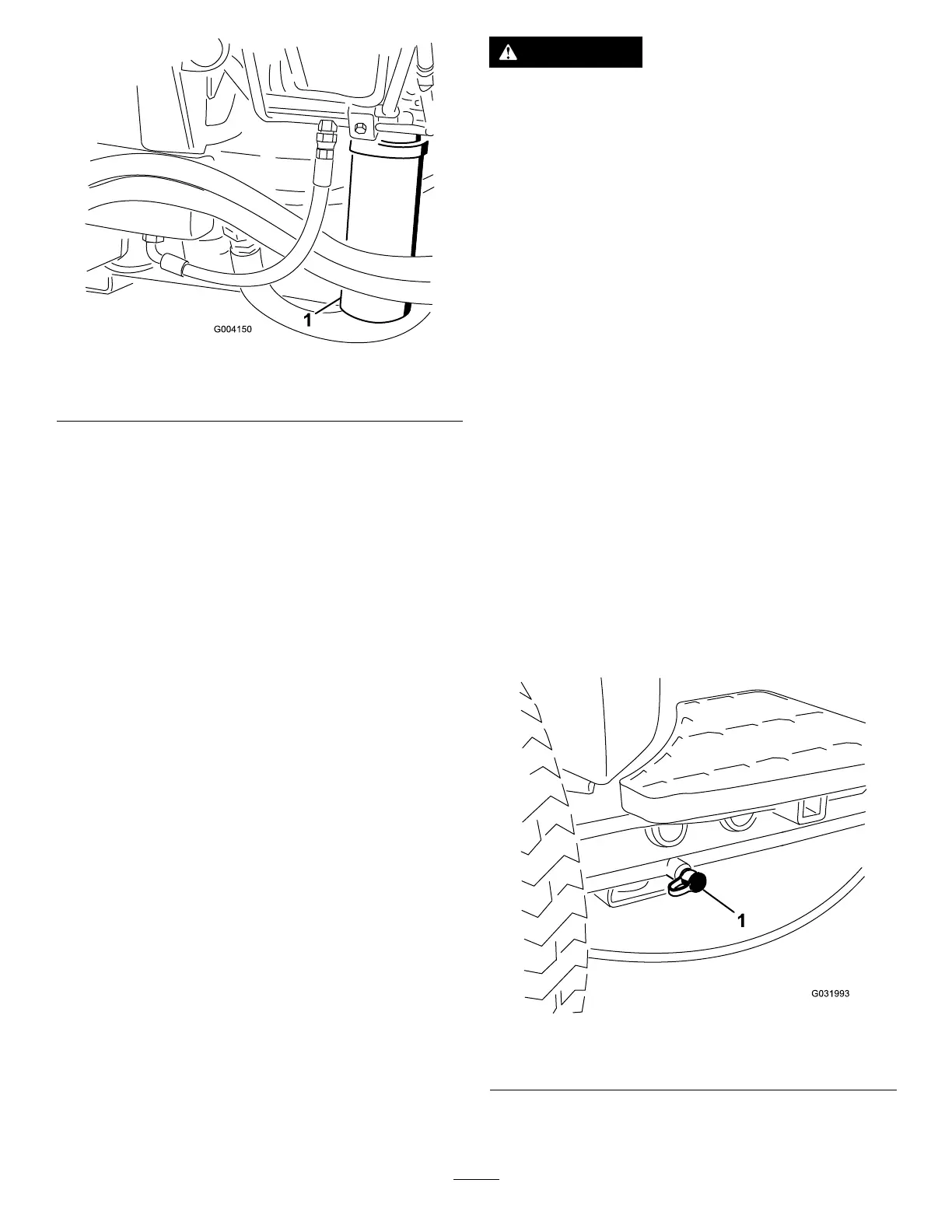

g031993

Figure69

1.Traction-circuittestport

Usethetestportsonthemowmanifoldblock(Figure

70)toassistintroubleshootingthemowcircuit.

50

Loading...

Loading...