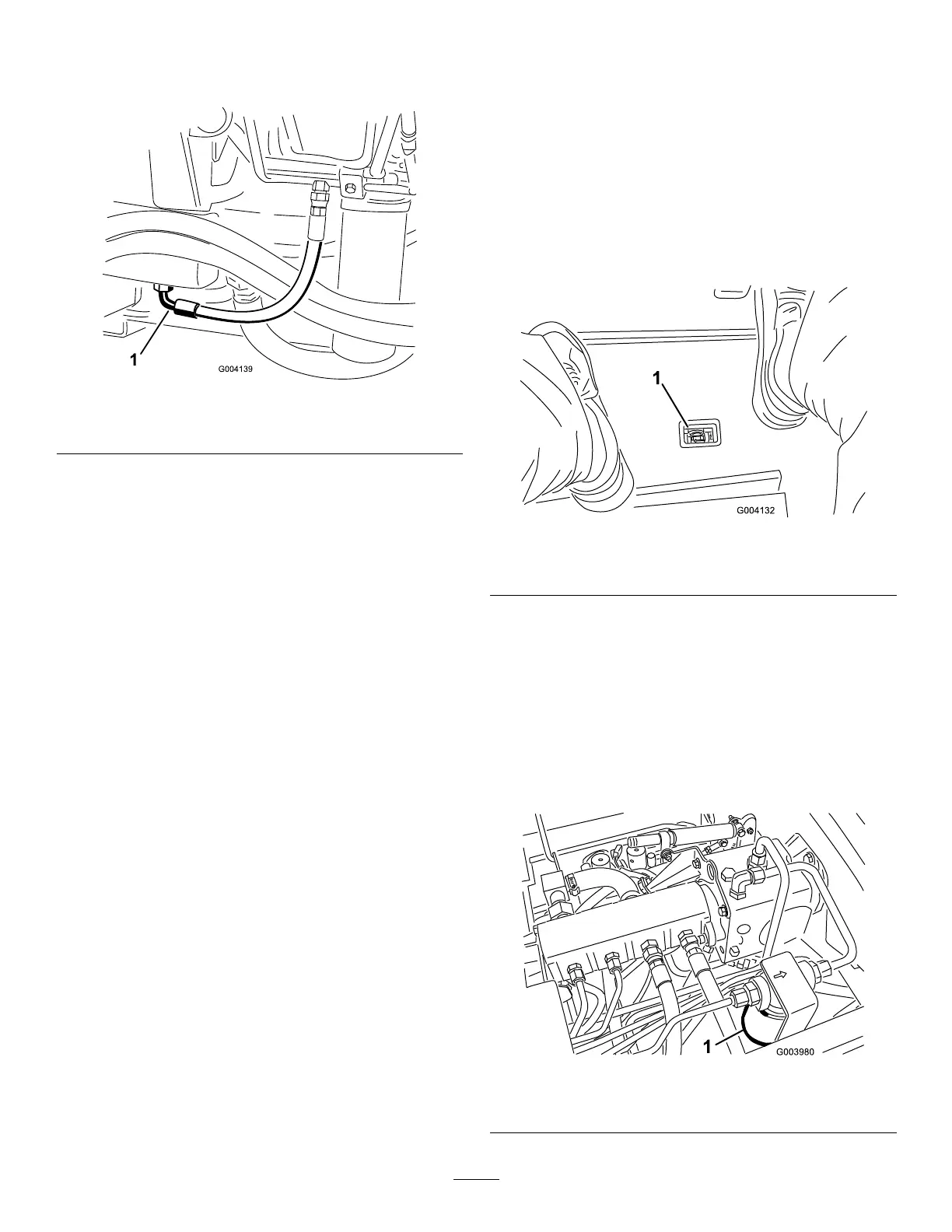

2.Placealargedrainpanunderthettingsecured

tothebottomofthehydraulic-uidreservoir

(Figure65).

g004139

Figure65

1.Hose

3.Disconnectthehosefromthebottomofthe

ttingandletthehydraulicuidowintothe

drainpan.

4.Installthehosewhenhydraulicuidstops

draining.

5.Fillthereservoirwithapproximately56.7L(15

USgallons)ofhydraulicuid;refertoChecking

theHydraulic-FluidLevel(page48)

Important:Useonlythehydraulicuids

specied.Otheruidscouldcausesystem

damage.

6.Installthereservoircap.

7.Starttheengineanduseallofthehydraulic

controlstodistributehydraulicuidthroughout

thesystem.Alsocheckforleaks.

8.Stoptheengine.

9.Checkthelevelofthehydraulicuidandadd

enoughtoraiseleveltotheFullmarkonthe

dipstick.

Important:Donotoverllthereservoir.

ReplacingtheHydraulic

Filters

ServiceInterval:Every800hours(Ormoreoftenif

theservice-intervalindicatorisin

theredzone).

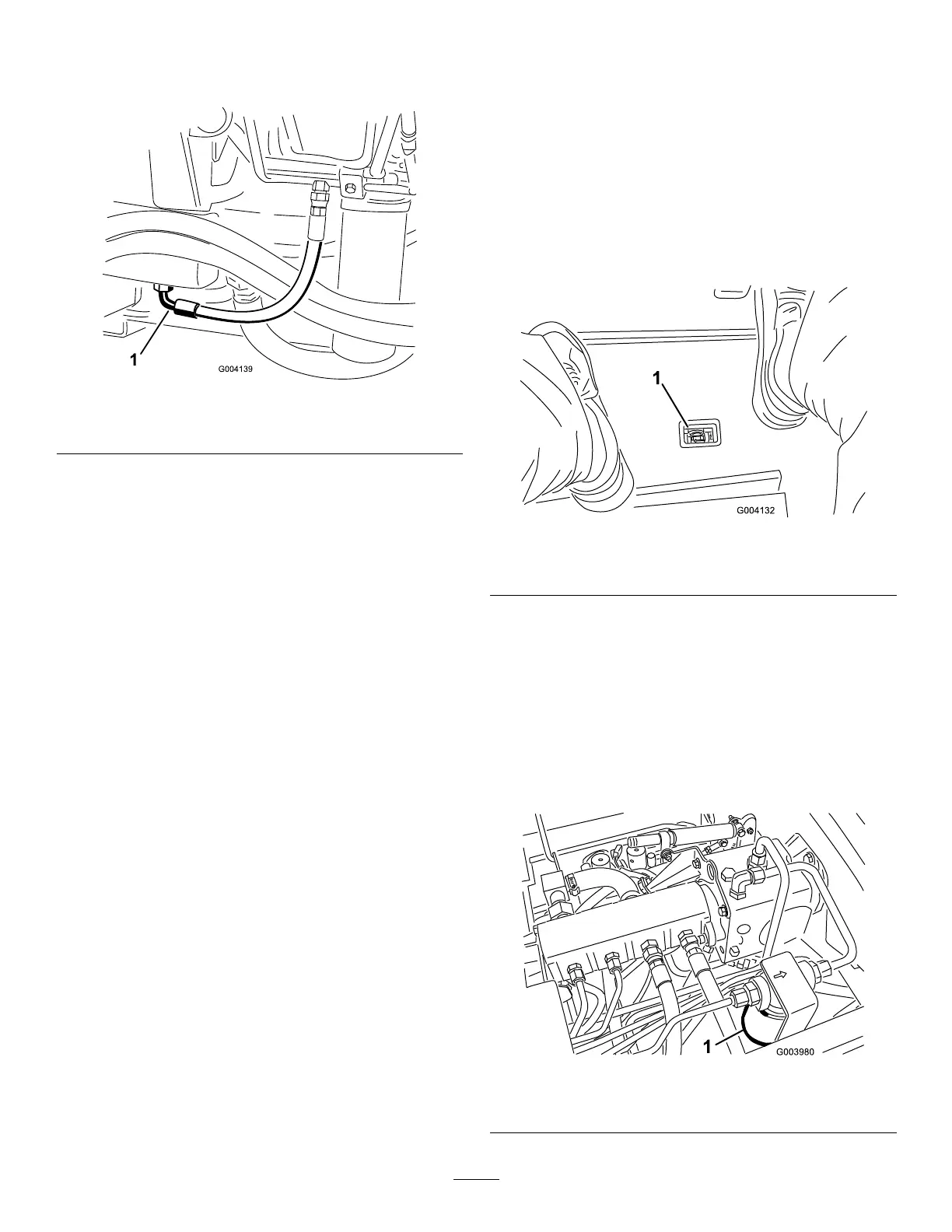

Thehydraulicsystemisequippedwitha

service-intervalindicator(Figure66).Withtheengine

runningatoperatingtemperature,viewtheindicator,it

shouldbeinthegreenzone.Whentheindicatorisin

theredzone,changethehydrauliclters.

g004132

Figure66

1.Hydraulic-lter-restrictionindicator

Important:Useofanyotherltersmayvoidthe

warrantyonsomecomponents.

1.Positionthemachineonalevelsurface,lower

thecuttingunits,stoptheengine,engagethe

parkingbrake,andremovethekeyfromthe

ignitionswitch.

2.Cleantheareaaroundtheltermountingarea

andplaceadrainpanunderlter(Figure67and

Figure68).

g003980

Figure67

1.Hydrauliclter

49

Loading...

Loading...