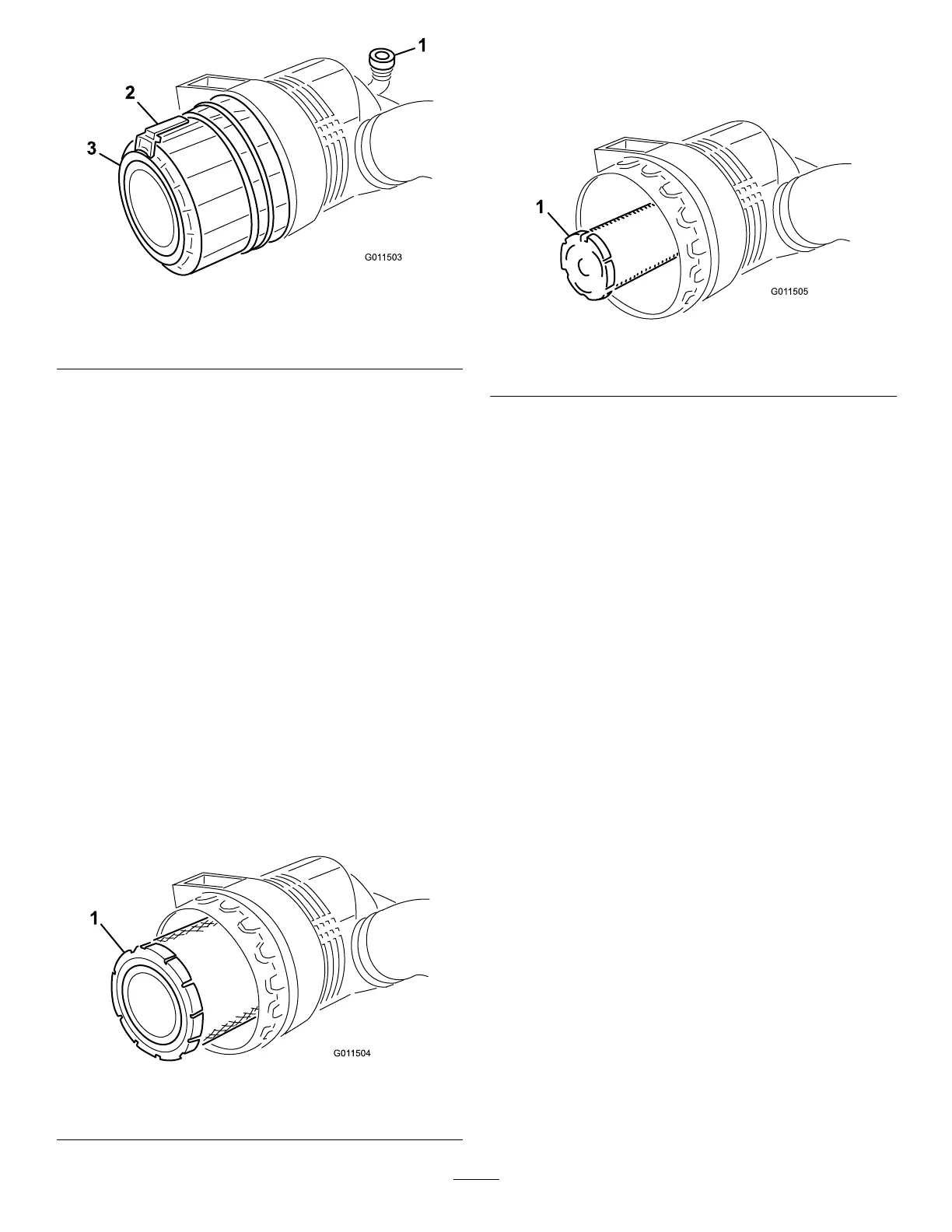

g011503

Figure47

1.Serviceindicator3.Cover

2.Latch

3.Removethecoverfromtheair-cleanerbody.

4.Beforeremovingthelter,uselow-pressure

air—275kPa(40psi),cleananddry—to

helpremovelargeaccumulationsofdebris

packedbetweenoutsideofprimarylterand

thecanister.Avoidusinghigh-pressureair,

whichcouldforcedirtthroughthelterinto

theintaketract.

Thiscleaningprocesspreventsdebrisfrom

migratingintotheintakewhentheprimarylter

isremoved.

5.Removeandreplacetheprimarylter(Figure

48).

Cleaningoftheusedelementisnot

recommendedduetothepossibilityofdamage

totheltermedia.Inspectthenewlterfor

shippingdamage,checkingthesealingendof

thelterandthebody.Donotuseadamaged

element.

Insertthenewlterbyapplyingpressuretothe

outerrimoftheelementtoseatitinthecanister.

Donotapplypressuretotheexiblecenter

ofthelter.

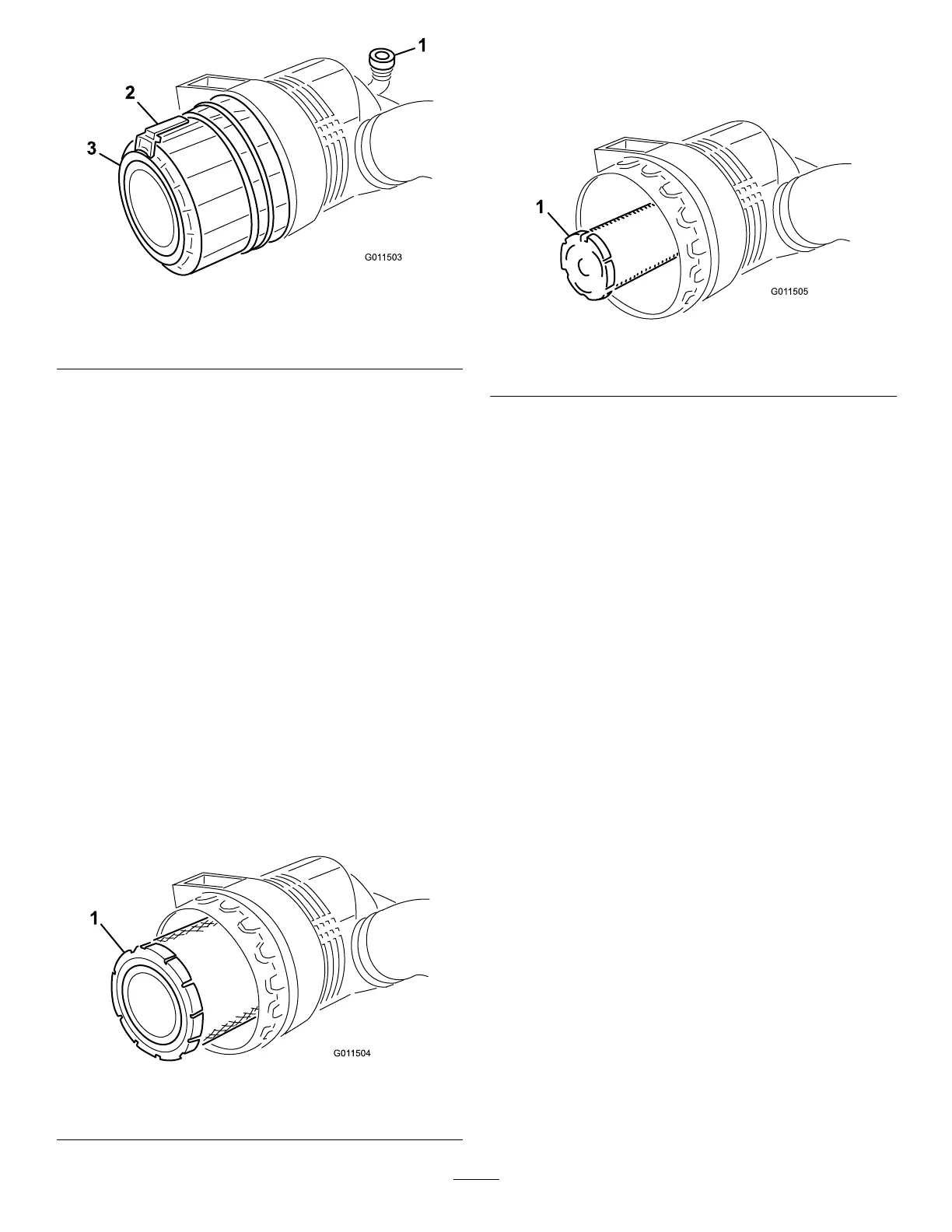

g011504

Figure48

1.Primarylter

Important:Neverattempttocleanthesafety

lter(Figure49).Replacethesafetylter

withanewoneafterevery3primarylter

services.

g011505

Figure49

1.Safetylter

6.Cleanthedirt-ejectionportlocatedinthe

removablecover.

7.Removetherubberoutletvalvefromthecover,

cleanthecavity,andinstalltheoutletvalve.

8.Installthecover,orientingtherubberoutletvalve

inadownwardposition—betweenapproximately

5o’clockto7o’clockwhenviewedfromtheend.

9.Resettheindicator(Figure46)ifitshowsred.

CheckingtheLevelofthe

EngineOil

ServiceInterval:Beforeeachuseordaily

Theengineisshippedwithoilinthecrankcase;

however,theoillevelmustbecheckedbeforeand

aftertheengineisrststarted.

Thecrankcasecapacityisapproximately9.5L(10

USqt)withthelter.

Usehigh-qualityengineoilthatmeetsthefollowing

specications:

•APIClassicationLevelRequired:CH-4,CI-4,or

higher.

•Preferredoil:SAE15W-40:above-18°C(0°F)

•Alternateoil:SAE10W-30or5W-30(all

temperatures)

Note:ToroPremiumEngineoilisavailable

fromyourdistributorineither15W-40or10W-30

viscosity.

Note:Thebesttimetochecktheengineoilis

whentheengineiscoolbeforeithasbeenstarted

fortheday.Ifithasalreadybeenrun,allowthe

oiltodrainbackdowntothesumpforatleast10

minutesbeforechecking.Iftheoillevelisator

42

Loading...

Loading...