ElectricalSystem

Maintenance

ElectricalSystemSafety

•Disconnectthebatterybeforerepairingthe

machine.Disconnectthenegativeterminalrst

andthepositivelast.Connectthepositiveterminal

rstandthenegativelast.

•Chargethebatteryinanopen,well-ventilated

area,awayfromsparksandames.Unplugthe

chargerbeforeconnectingordisconnectingthe

battery.Wearprotectiveclothinganduseinsulated

tools.

ChargingandConnecting

theBattery

1.Parkthemachineonalevelsurface,lowerthe

cuttingunits,engagetheparkingbrake,shutoff

theengine,andremovethekey.

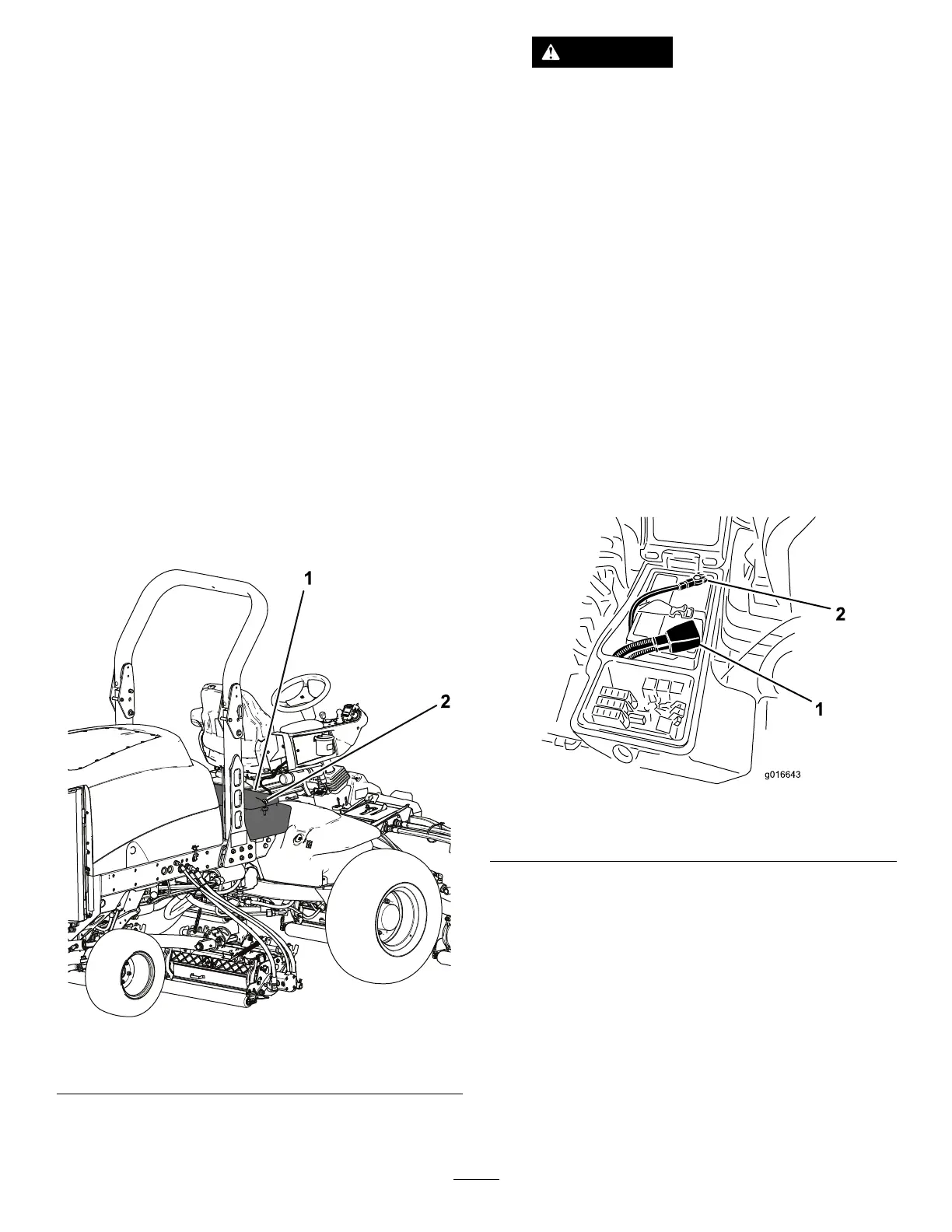

2.Unlatchandraisetheoperator'sconsolepanel

(Figure57).

g200376

Figure57

1.Operator'sconsolepanel

2.Latch

DANGER

Batteryelectrolytecontainssulfuricacid,

whichisfatalifconsumedandcauses

severeburns.

•Donotdrinkelectrolyteandavoid

contactwithskin,eyes,orclothing.

Wearsafetyglassestoshieldyour

eyesandrubberglovestoprotect

yourhands.

•Fillthebatterywherecleanwateris

alwaysavailableforushingtheskin.

3.Connecta3to4Abatterychargertothebattery

posts.

4.Chargethebatteryatarateof3to4Afor4to

8hours.

5.Whenthebatteryischarged,disconnectthe

chargerfromtheelectricaloutletandbattery

posts.

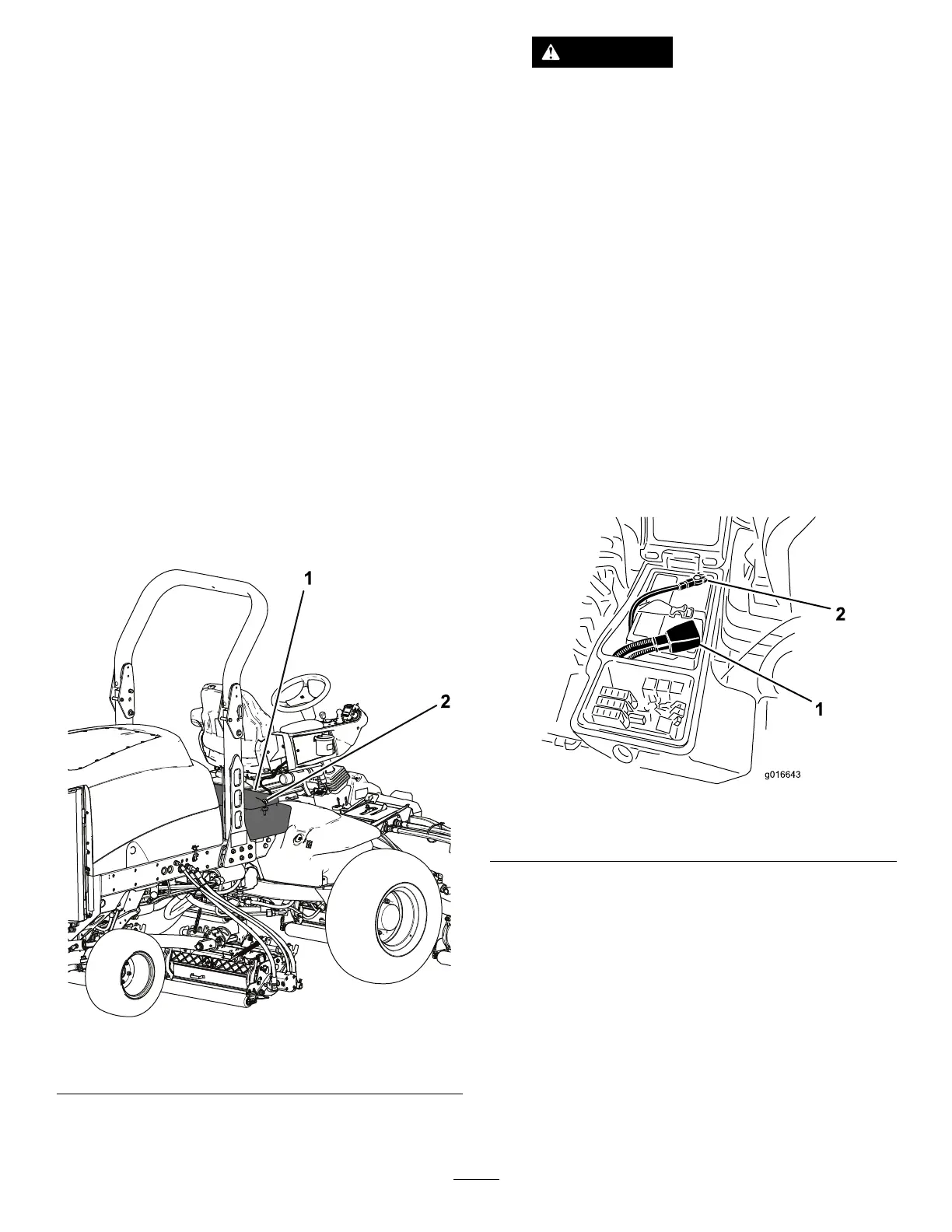

6.Installthepositivecable(red)tothepositive(+)

terminalandthenegativecable(black)tothe

negative(-)terminalofthebattery(Figure58).

g016643

Figure58

1.Positivebatterycable2.Negativebatterycable

7.Securethecablestothepostswithcapscrews

andnuts.

Makesurethatthepositive(+)terminalisallof

thewayontothepostandthecableispositioned

snugtothebattery.Thecablemustnotcontact

thebatterycover.

8.Slidetherubberbootoverthepositiveterminal

topreventapossibleshortfromoccurring.

9.CoatbothbatteryconnectionswithGrafo112X

(skin-over)grease,T oroPartNo.505-47,

petroleumjelly,orlightgreasetoprevent

corrosion.

10.Slidetherubberbootoverthepositiveterminal.

46

Loading...

Loading...