A.Installthebelt-driveassemblyusingthe

previouslyremovedbolts,andensurethat

thesideplaterotatesfreely(Figure6).

B.Installthelowerpulleyontothereeldrive

shaft,securingitwith2setscrewsontothe

keyontheshaft(Figure5).

C.Torquethesetscrewsto7to7.5N·m(60

to65in-lb).

D.Installthedrivebeltandtensionitas

describedinthetractionunitOperator’s

Manual.

13.Securethegroomerdrivegeartothereelshaft

ontherightsideofthereel(Figure10),and

torqueto170N·m(125ft-lb).

Note:Theuseofanimpactgunisnotenough

toensureproperinstallation.Failingtoproperly

torquethedrivepulleycanresultintheassembly

unscrewingitselfduringoperation.

14.Installandsecuretheidlergears(Figure10)and

torquethecapscrewsto13.5N·m(120in-lb).

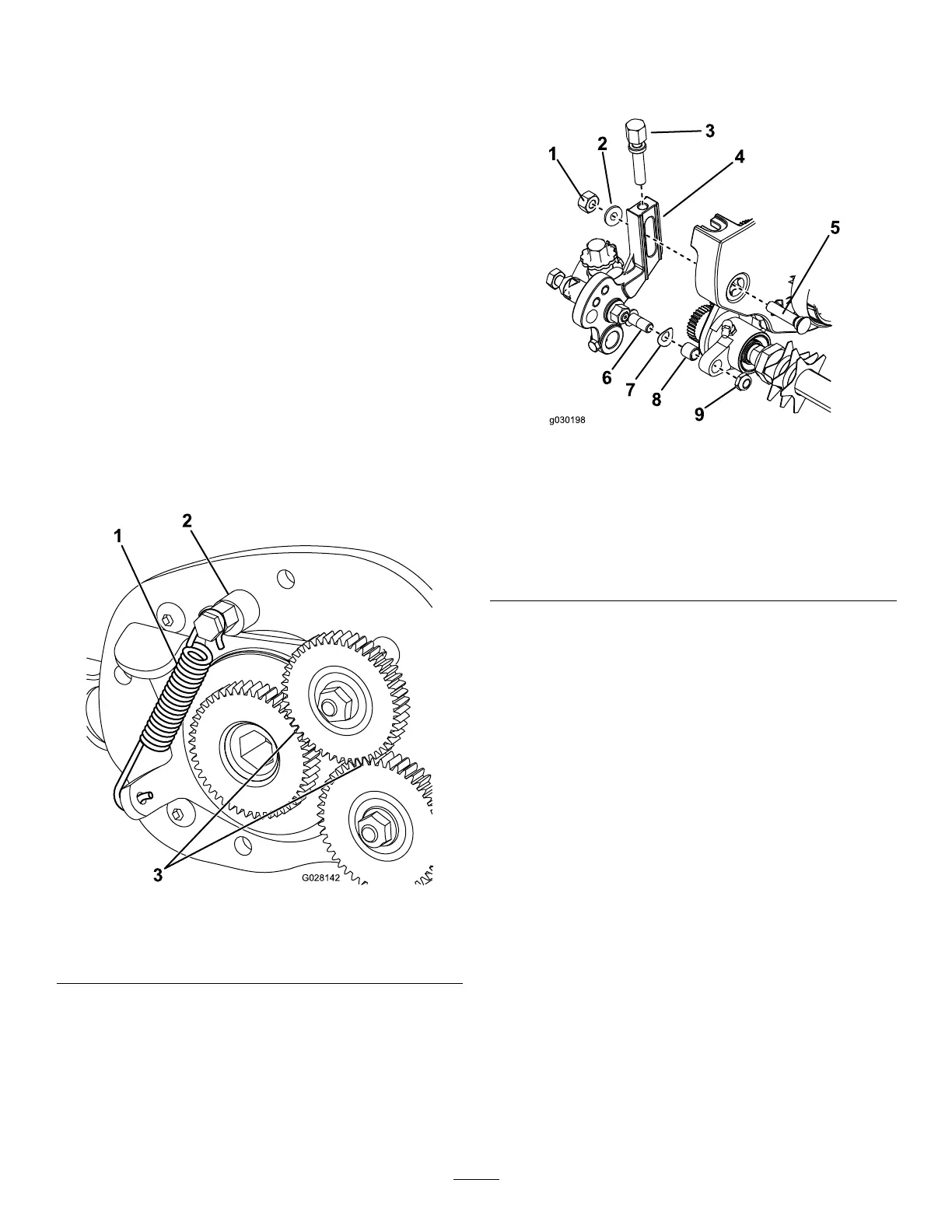

15.Installtheidlertensionspring(Figure12).

g028142

Figure12

1.Tensionspring3.Measurehere.

2.Eccentricstop

16.Withtheidlergearengaged,useasparkplug

gappingtooltocheckthatthereisa0.38to0.45

mm(0.015to0.018inch)gapbetweenthedriver

andxedidlergear(Figure12).

Note:Youcanadjustthegapbyrotatingthe

eccentricstopfortheidlergear.

InstallingtheAdjusterArms

1.Installthebushingintheholeintheright

groomer-driveassembly(Figure13).

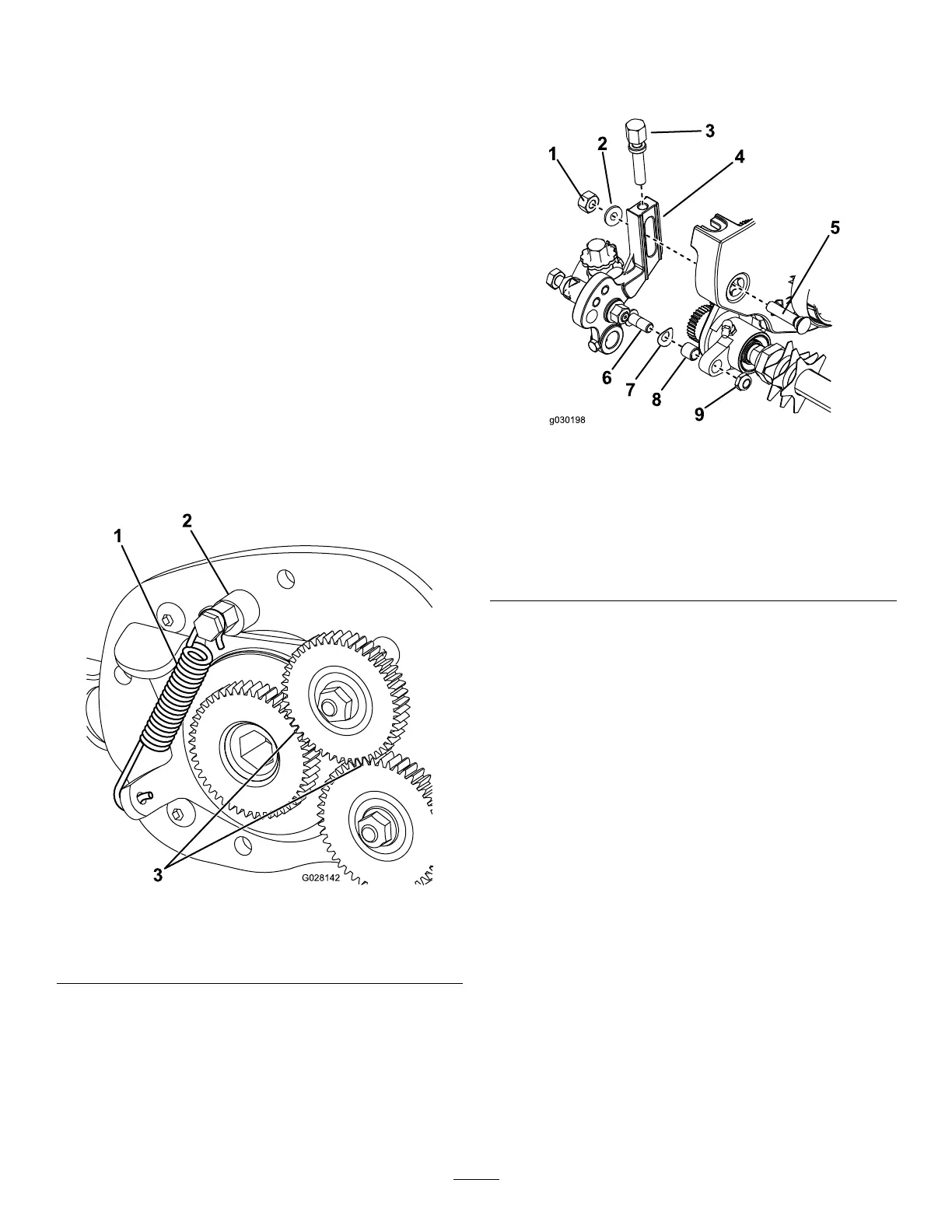

g030198

Figure13

1.Nut

6.Rodendofthe

height-of-cutassembly

2.Specialwasher7.Springwasher

3.Height-of-cutscrew

8.Bushing

4.Adjuster-armassembly9.Locknut

5.Plowbolt

2.Threadtheheight-of-cutadjustingscrewintothe

topoftherightadjuster-armassembly(Figure

13).

3.Installthespringwasherontotherodendofthe

height-of-cutarmassembly(Figure13).

4.Installtherightadjuster-armassemblytothe

cuttingunitsideplateusingaplowbolt,nut,and

specialwasher(Figure13).

Note:Makesurethattherodendofthe

height-of-cutarmassemblyslidesintothe

bushingintheholeinthegroomerdrive

assembly.

5.Securetheadjuster-armassemblyrodendto

thegroomerdriveassemblywiththelocknut

(Figure13).

Note:Donotovertightenthelocknut.The

washershouldbecompressedbutthearmmust

befreetopivot.

6

Loading...

Loading...