Figure39

1.Bolts

2.Cover

2.Brushorblowoutdebrisfromtheinsideoftheshield

andaroundalltheparts.

3.Holda0.25mm(0.010-inch)feelergauge,apieceof

paper,oranotecardagainstthewallandslideitdown

behindthebelttensionspring.

Note:Ifthereisavisiblegapbetweenthegaugeand

thespring,tightentheadjustingboltandthenutuntil

thepaperbarelyslidesfreelyinandoutofthegap

(Figure40).

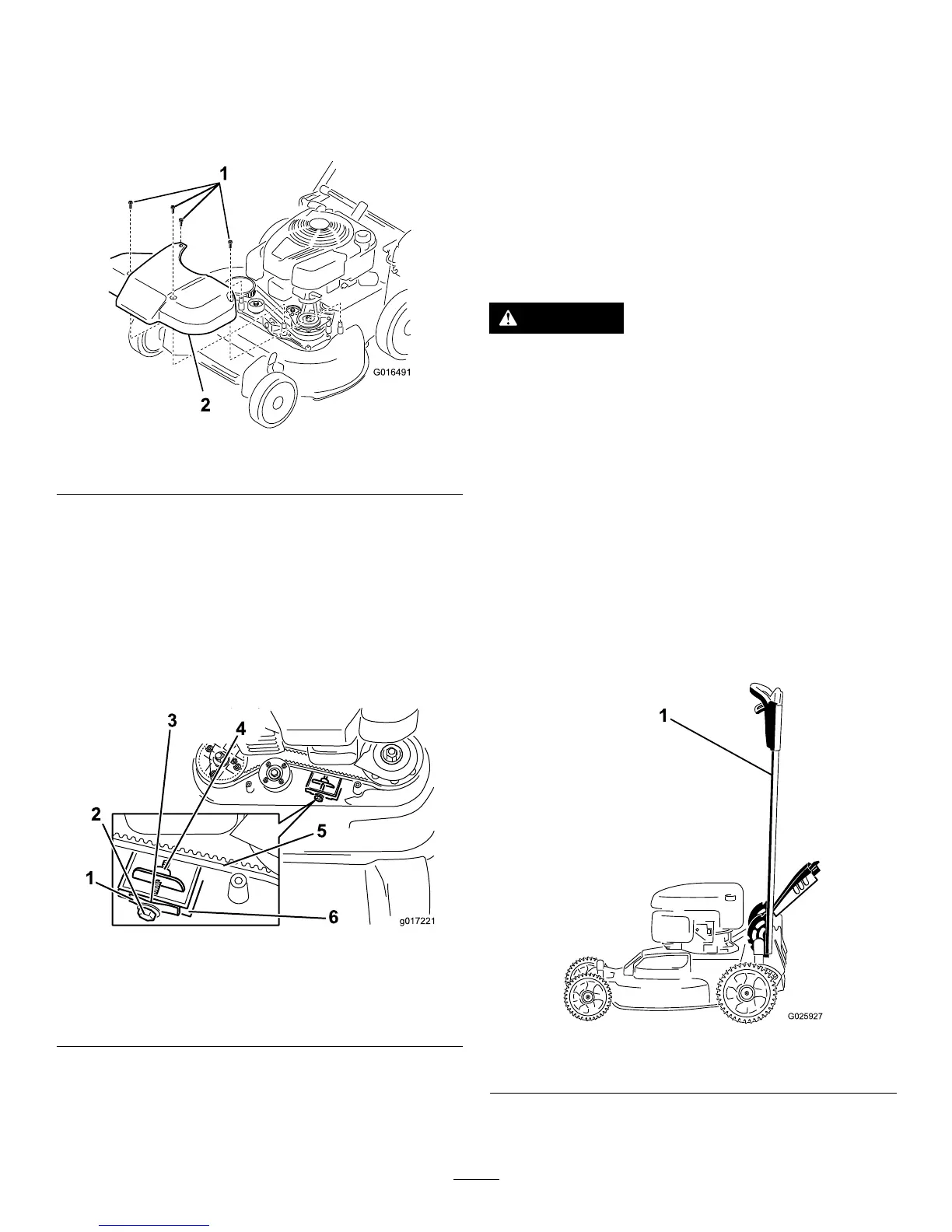

Figure40

1.Belt-tensionspring4.Adjustingnut

2.Adjustingbolt5.Blade-drivebelt

3.Gap

6.Wall

Important:Donotovertightentheadjustingbolt.

Thiscoulddamagetheblade-drivebelt.

4.Installtheblade-drivesystemcoverthatyoupreviously

removed.

ServicingtheCuttingBlades

ServiceInterval:Yearly

Important:

Y ou will need a torque wr ench to install the

blades pr oper l y .

Ifyoudonothaveatorquewrenchor

areuncomfortableperformingthisprocedure,contact

anAuthorizedServiceDealer.

Examinethebladesforsharpnessandanywearordamage

wheneveryourunoutofgasoline.Ifthebladeedgesare

dullornicked,havethemsharpenedorreplacetheblades.

Ifabladeisworn,bent,damagedorcracked,replaceit

immediatelywithagenuineTororeplacementblade.

DANGER

Awornordamagedbladecanbreak,andapiece

ofthebladecouldbethrowntowardtheoperator

orabystander,resultinginseriouspersonalinjury

ordeath.

•Inspectthebladesperiodicallyforwearor

damage.

•Replaceawornordamagedblade.

Note:Maintainsharpbladesthroughoutthecuttingseason,

becausesharpbladescutcleanlywithouttearingorshredding

thegrassblades.

PreparingtoServicetheCuttingBlades

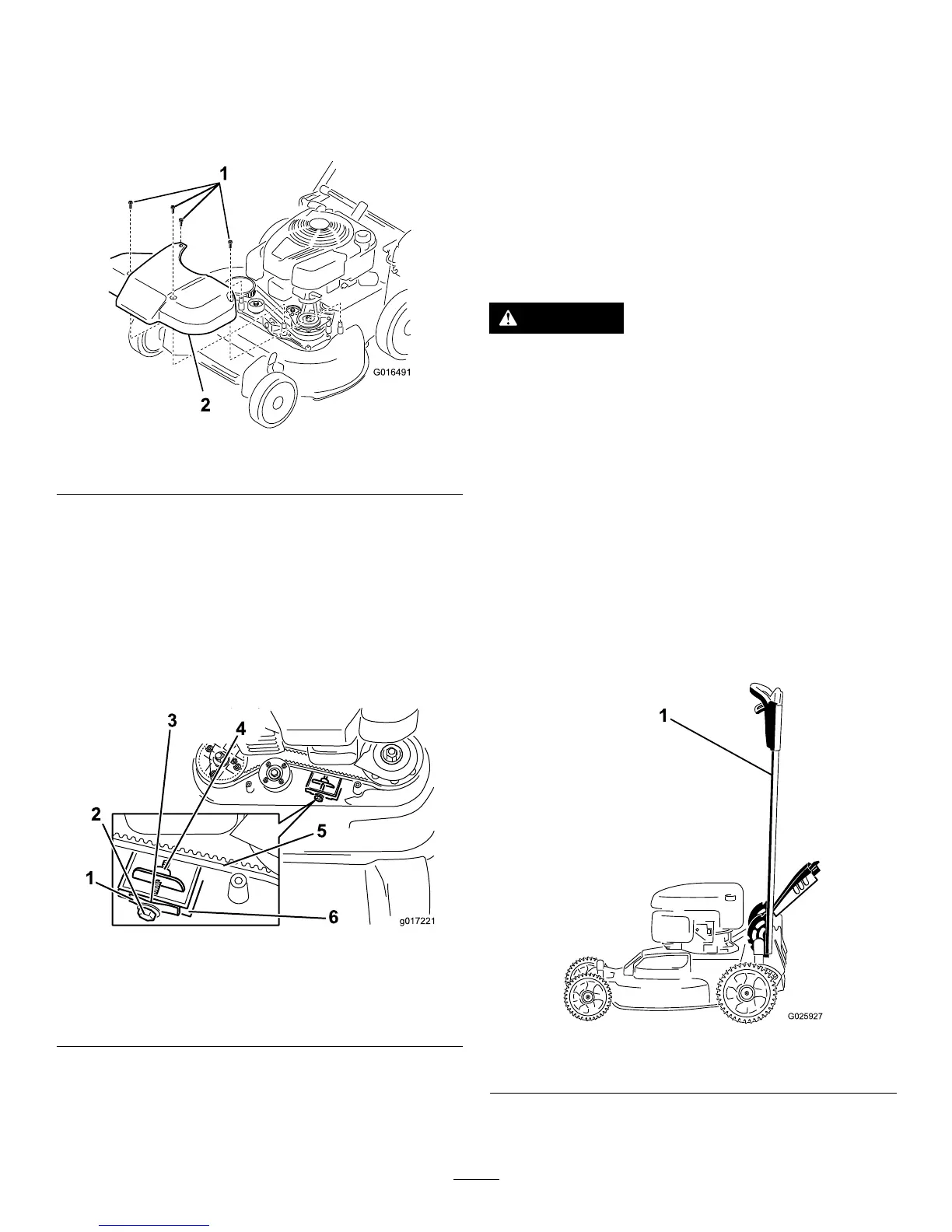

1.Lockthehandleintheverticalposition(Figure41);

refertoAdjustingtheHandleHeight(page11).

Loading...

Loading...